We recently connected with Diana Hall and have shared our conversation below.

Diana, thanks for joining us, excited to have you contributing your stories and insights. Let’s kick things off with your mission – what is it and what’s the story behind why it’s your mission?

I’m a chemical engineer and started ActivArmor in 2014 while I was running a mentoring program for children in poverty. After working in Fortune 500 companies across the country and finishing my master’s degree in Business,I moved back to my hometown of Pueblo, CO to help children on Pueblo’s east side.

Through the mentoring program, I worked with children involved in domestic violence situations and living in substandard conditions. They would frequently have casts on that would get filthy after weeks of wear – just playing on the playground like kids. The children with casts for 5 weeks could not even wash their hands to have a snack! One girl had bed bugs in her cast and another little boy, in first grade, was not able to keep his cast dry in a bag outside the shower by himself, as he was being raised by his disabled grandparents. He got his cast wet, and did not want to get in trouble, and had no transportation to get it replaced, so he did not tell and ended up with permanent scarring on his arm from the skin breakdown.

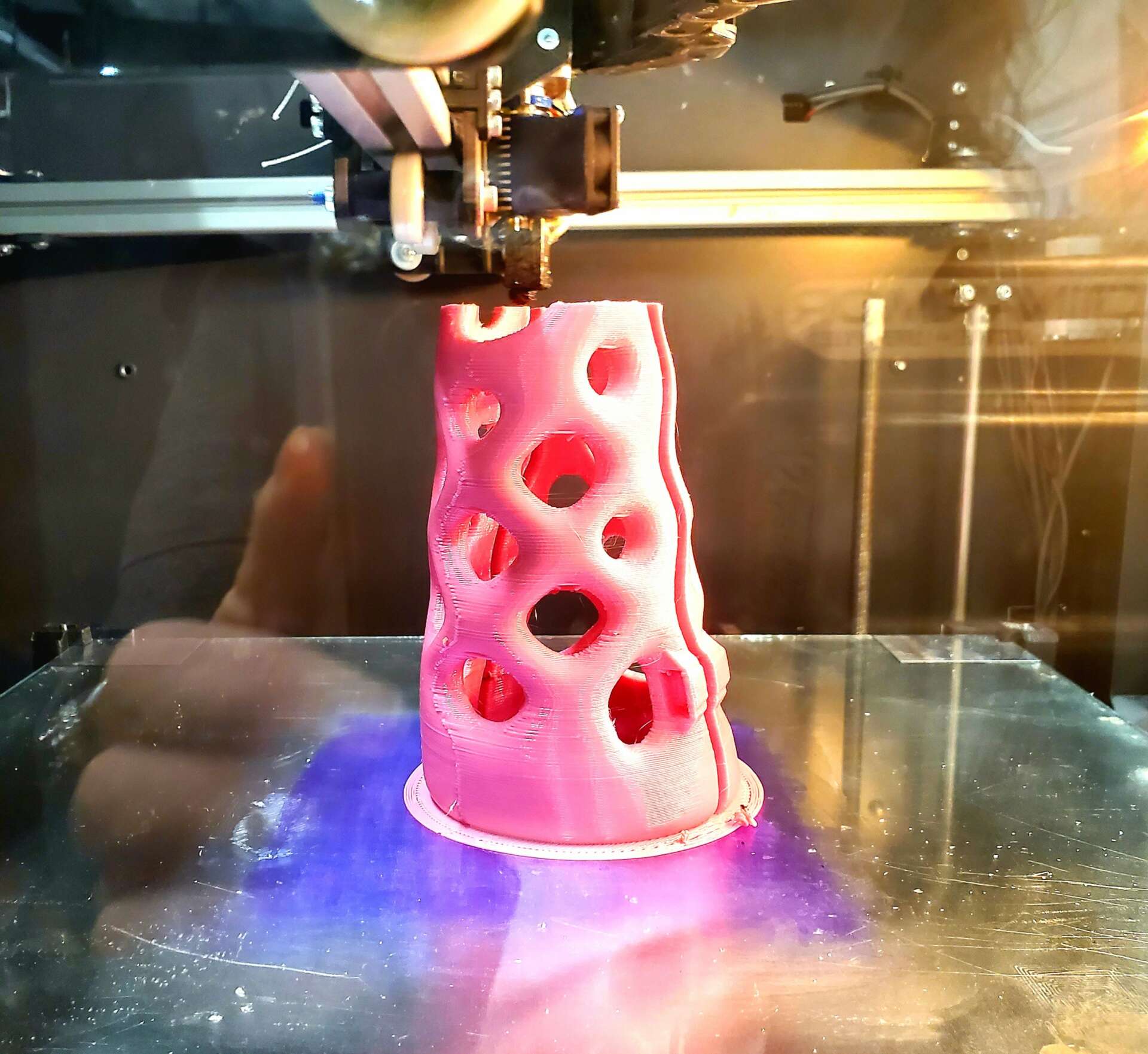

I knew that there was a better alternative to casting and splinting through the use of additive manufacturing. Hygienic materials and breathable, custom-fit designs allow for improved healing and treatment options, as well as lifestyle freedom for the patients. But there were many reasons why this technology and product was not available to American consumers.

There was the issue of time – design and fabrication of custom splints by hand takes both time and labor.

There was the issue of design – finding the ideal balance of thickness and coverage area (for protection of a broken limb) and lightweight breath-ability (for comfort and freedom for the patient).

The issue of materials – Making 3D printed products durable enough to be used in sports, while still low-profile enough to allow for maximized mobility and freedom of movement.

There was the issue of regulatory oversight – ensuring the 3D printed materials and finished product were biocompatible and non-porous (would not trap moisture or bacteria against the skin)

There was the issue of fit – using the right equipment with the right process and quality controls to ensure a precise fit to the limb for accurate immobilization of parts as small as fingers for comfort and ideal healing outcomes.

The issue of compliance – how to make them non-removable like a cast, but also removable like a splint, applicable for both acute injuries and chronic conditions.

There was the issue of clinic adaptability – exchanging a technique and process used for decades in orthopedic practice for a digital scan.

There was the issue of cost – making the latest technology in precision scanning hardware and software affordable, including the labor of CAD design unique to each patient, fabrication and hand-finishing of each device in an FDA registered manufacturing facility, and making that all available in the same price range as traditional splints, and covered by insurance.

We addressed these challenges with a team of advisors – the top orthopedic surgeons and sports medicine doctors, regulatory compliance experts, athletes and patients over 3 years of field tests and hundreds commercial sales. ActivArmor is now available in clinics across the globe, being worn by professional athletes and patients worldwide.

Great, appreciate you sharing that with us. Before we ask you to share more of your insights, can you take a moment to introduce yourself and how you got to where you are today to our readers

This is a follow-up to the last article.

We are now transitioning from a manufacturer of custom casts to a SaaS company – providing automated digital design software that allows any provider to quickly and easily custom design a cast for fabrication right there in the clinic.: https://youtu.be/NYJZk0o23FM

Have you ever had to pivot?

The two things keeping our custom casts from becoming the new standard of care for fractures were time and cost. We have spent 3.5 years in development on the digital design platform and turnkey fabrication system that gives providers the ability to fabricate custom devices in a few hours for less than the cost of a traditional cast.

How did you put together the initial capital you needed to start your business?

We have raised over $2M in investment and over $1M in sales revenues to date, and currently have a 506c round open for accredited investors who would like to own a piece of our growing company.