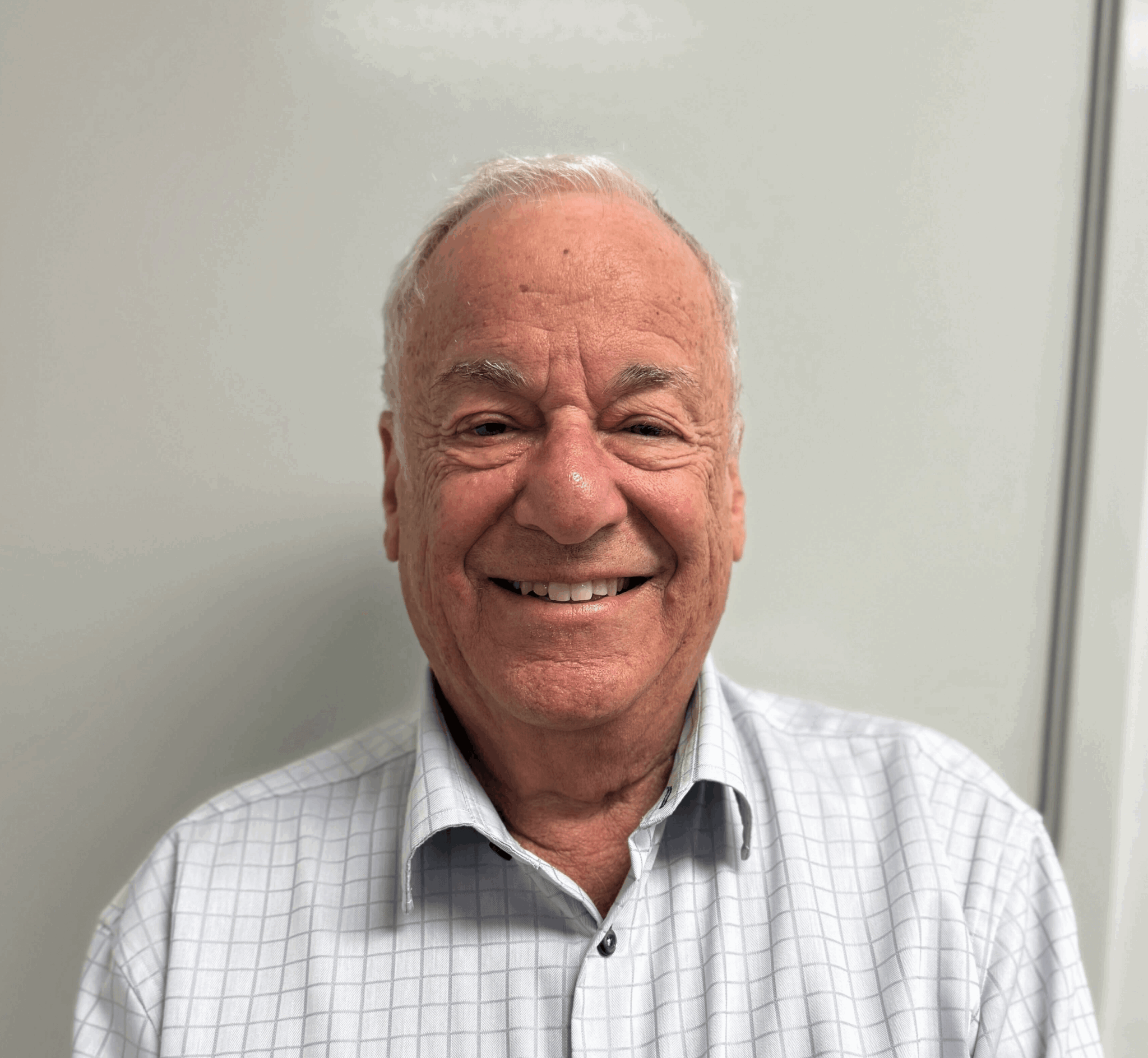

Alright – so today we’ve got the honor of introducing you to Steve Ustin. We think you’ll enjoy our conversation, we’ve shared it below.

Steve, thanks for taking the time to share your stories with us today Often outsiders look at a successful business and think it became a success overnight. Even media and especially movies love to gloss over nitty, gritty details that went into that middle phase of your business – after you started but before you got to where you are today. In our experience, overnight success is usually the result of years of hard work laying the foundation for success, but unfortunately, it’s exactly this part of the story that most of the media ignores. Can you talk to us about your scaling up story – what are some of the nitty, gritty details folks should know about?

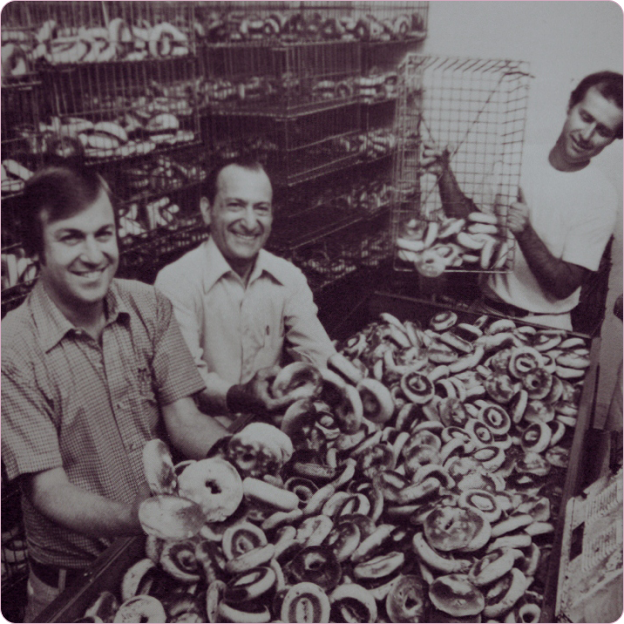

Our journey began in 1947, when my father set out to do something bold: open the first bagel company in Southern California. At the time, most people on the West Coast had never even heard of a bagel, let alone tasted one. It took nearly a month to find the right location — a modest bakery in Los Angeles — but that storefront became the starting point of something much bigger than we could have imagined.

Shortly after opening, we caught our first big break: a large local bakery took a chance on us. That single customer quickly became 70–80% of our business. While my father and his partner ran operations, I worked in the bakery every day, learning every part of the process — from mixing dough to loading ovens — absorbing everything I could.

In 1972, when I was in my mid-20s, I officially became a partner in the business. My father had faith in my judgment and allowed me to make key decisions early on. With that trust came both opportunity and hard-earned lessons.

Two of the most important lessons I learned quickly:

– Always have backups for every key employee role.

– Never rely too heavily on one customer — no matter how big or reliable they seem.

Both were tough to learn, but they helped shape how we scaled the business in the years ahead.

As we looked to grow beyond our original customer base, we made a strategic decision: to enter the grocery market. That meant long hours, countless meetings, and a lot of samples. I became our first sales rep, hitting the road across Los Angeles and Southern California, working to get our bagels into grocery chains. It worked.

We secured accounts with some of the largest grocery chains in the region, which gave us two major advantages:

1. We could diversify our production and no longer be reliant on any single customer.

2. We could scale efficiently while keeping quality consistent.

Eventually, the business grew to the point where we hired a full-time sales representative and brought on a broker to help maintain our growing portfolio and expand even further.

About 30 years ago, our work and reputation caught the attention of a major East Coast grocery chain. They became — and remain — one of our largest customers. From day one, we made a promise: we’re available 24/7. If any issues arose, my father and I would personally fly out to address them. Once, they even tested us on that promise — and we showed up in person.

That dedication earned us trust — and long-term business.

One of my proudest moments came in 1974, when I convinced my father to open our first Western Bagel retail store in Woodland Hills. He was hesitant, but I believed in the opportunity. On our first day, we sold out of bagels by noon — a clear sign that our community was ready.

From there, we opened 1–2 new stores each year, all self-funded. We hired a dedicated operations manager, secured locations in A-grade neighborhoods and shopping centers, and built a retail presence that could withstand competition. Others tried to move in, but few could match our quality, service, and loyal customer base.

We also became a staple in the community — donating bagels to local schools, organizations, and events. Today, we operate 10 retail stores across the San Fernando Valley, Santa Clarita, and Thousand Oaks.

Like any growing business, we hit our share of roadblocks.

At one point, a labor strike among our production union workers pushed us to find alternatives. That’s when we invested in a Thompson Bagel Machine — a semi-automated system that reduced labor costs while preserving quality. It marked the end of hand-made bagels in our main production facility and opened the door to future innovation.

In 1980, we installed a tunnel oven that more than doubled our baking capacity — up to 2,000 bagels per hour — and began cryo-freezing bagels, which allowed us to serve customers far beyond our region. One major national retailer became 20–25% of our business, which reinforced a critical rule we still follow today: never dedicate more than 25% of our production to one customer.

By 1994, demand had outgrown our original bakery. We needed more capacity to continue meeting orders without sacrificing freshness or service. So, we built a second production facility with all-new equipment and a new team of skilled, adaptable employees.

Of course, not everything went to plan. Our brand-new oven — designed to bake 2,000 dozen bagels per hour — initially produced only 300 dozen. We had to rely on our old-school revolving ovens to get orders out on time, but we didn’t let our customers down. We fixed the issue and kept moving forward.

To outsiders, a bagel might seem like a simple product — but anyone in the business knows better. The shape, size, texture, and taste can vary wildly. There are countless ways to make a “plain” bagel, and every customer has different expectations. Our flexibility and experience have allowed us to craft bagels that meet the specific needs of customers across the board — from delis and restaurants to schools, donut shops, and private label grocery programs.

Looking back, the journey wasn’t easy. But we’ve always relied on a few core beliefs:

– Scared money never wins.

– Optimism is essential.

– You must plan for success.

– Stay humble, always.

– Adapt with the times or get left behind.

Those lessons — combined with decades of hard work, smart decision-making, and a deep love for what we do — are what turned Western Bagel from a single Los Angeles bakery into a multi-generational business and Southern California staple.

Steve, before we move on to more of these sorts of questions, can you take some time to bring our readers up to speed on you and what you do?

You could say I grew up in the business — literally. From the time I was about 7 or 10 years old, I was going to work with my dad at the bakery. At the time, it started as a kind of punishment from my mom — but it didn’t feel like that to me. I loved it. The smells, the process, the rhythm of the bakery — I was hooked from day one.

I started learning how to roll bagels as a kid, and the more time I spent in the bakery, the more I knew this was what I wanted to do with my life. I was fortunate to discover my passion at such a young age — a gift many people spend their lives searching for.

When I got to college, I found it hard to stay focused in class because all I could think about was getting back to the bakery. The textbooks didn’t interest me the way hands-on work did. I knew my education would come from doing, not just studying.

When I officially became my dad’s business partner, I started stepping into executive decision-making roles. That’s where I really began to understand what it takes to lead a business — especially a family business. Managing people became a huge part of my daily life, and I quickly realized something that many leaders overlook: common sense often goes further than book smarts.

I learned that some employees just needed the right environment or position to thrive. I also learned the importance of setting clear expectations, creating boundaries, and maintaining respect — especially when family members are part of the team. In a family business, it’s critical to have one clear decision-maker to keep things running smoothly.

At Western Bagel, we’ve been proudly serving customers for over 78 years, making us one of the longest-standing bagel companies in California. We specialize in baking high-quality, freshly made bagels for a wide variety of customers — from retail shoppers in our stores to major grocery chains and national private-label partners.

We don’t just make bagels — we solve problems for our clients:

– We’re a dependable supplier for grocery and foodservice partners.

– We create customizable bagel options to meet private-label and branding needs.

– We help our retail customers enjoy consistent, top-quality products with friendly service every time.

What truly sets us apart is our reliability, flexibility, and hands-on leadership. We’re available 24/7 for our customers. We respond quickly. We find solutions. We adjust to changing times. And through it all, we never compromise on quality.

Without question, I’m most proud of our longevity. Running a business in California for nearly eight decades is no easy feat — especially with the strict regulations and challenges that come with operating here. But we’ve done it by staying true to our values and always putting customers first.

Even during the toughest times — including the COVID-19 pandemic — we stayed strong. We remained open, kept our customers happy, and ensured our products and services never wavered.

Whether you’re a fan, a new customer, a vendor, or someone considering working with us, here’s what you should know:

– We are loyal — to our customers, our team, and our mission.

– We are hardworking — always ready to do what it takes to deliver.

– We are reliable — you can count on us.

– We are family-driven — built on tradition, but always looking ahead.

– We’re proud of what we’ve built — and even more excited about where we’re headed.

We’d love to hear about how you keep in touch with clients.

While I’ve always preferred face-to-face meetings — and believe there’s nothing more powerful than a handshake and a real conversation — I recognize that today’s world makes those moments harder to come by. That’s why staying in regular contact with our customers through email, phone calls, and occasional in-person visits remains a top priority for me and our team.

Our sales and retail departments are active daily on social media and email, engaging with fans, sharing product news, and keeping our community up to date on what’s happening at Western Bagel. These touchpoints allow us to stay connected with our loyal customers while also reaching new audiences in a way that’s timely and authentic.

Additionally, we’ve partnered with Society22, a PR firm that’s helping us expand our reach. Through their efforts, we’ve been featured in national and local publications, participated in community events, and even had the opportunity to share our story on podcasts — all of which help build deeper brand awareness and trust.

Whether it’s online, over the phone, or in person, we believe consistent, honest communication and showing up for our community are the keys to long-lasting relationships and brand loyalty.

Okay – so how did you figure out the manufacturing part? Did you have prior experience?

Yes, we proudly manufacture all our own products — and we’ve done so from the very beginning.

Fortunately, my father already knew how to make our signature bagels when he started the business, and he passed that knowledge down to me. I learned directly from him, hands-on, and over the years, we’ve continued to refine and improve our processes while still staying true to our roots. Manufacturing in-house has always been our preference because it gives us full control over quality, production capacity, and growth.

Producing everything ourselves allows us to:

– Maintain strict quality standards

– Adjust quickly to customer demand

– Scale responsibly and sustainably

– Work only with trusted equipment vendors and repair specialists

Of course, there are real challenges to manufacturing your own products — including high capital expenses, ongoing equipment maintenance, regulatory compliance, and hiring and retaining a strong, skilled workforce. But despite those challenges, manufacturing in-house has helped us build trust and confidence with our customers — they know we can deliver.

One of the biggest lessons we’ve learned along the way is this:

Never promise anything you can’t deliver.

Being realistic and honest in manufacturing timelines and capacity has been key to maintaining long-term relationships and our reputation in the industry.

Contact Info:

- Website: https://westernbagel.com/

- Instagram: https://www.instagram.com/westernbagel/

- Facebook: https://www.facebook.com/WesternBagel/

Image Credits

Western Bagel