We recently connected with Santanna Martin and have shared our conversation below.

Alright, Santanna thanks for taking the time to share your stories and insights with us today. Risking taking is a huge part of most people’s story but too often society overlooks those risks and only focuses on where you are today. Can you talk to us about a risk you’ve taken – it could be a big risk or a small one – but walk us through the backstory.

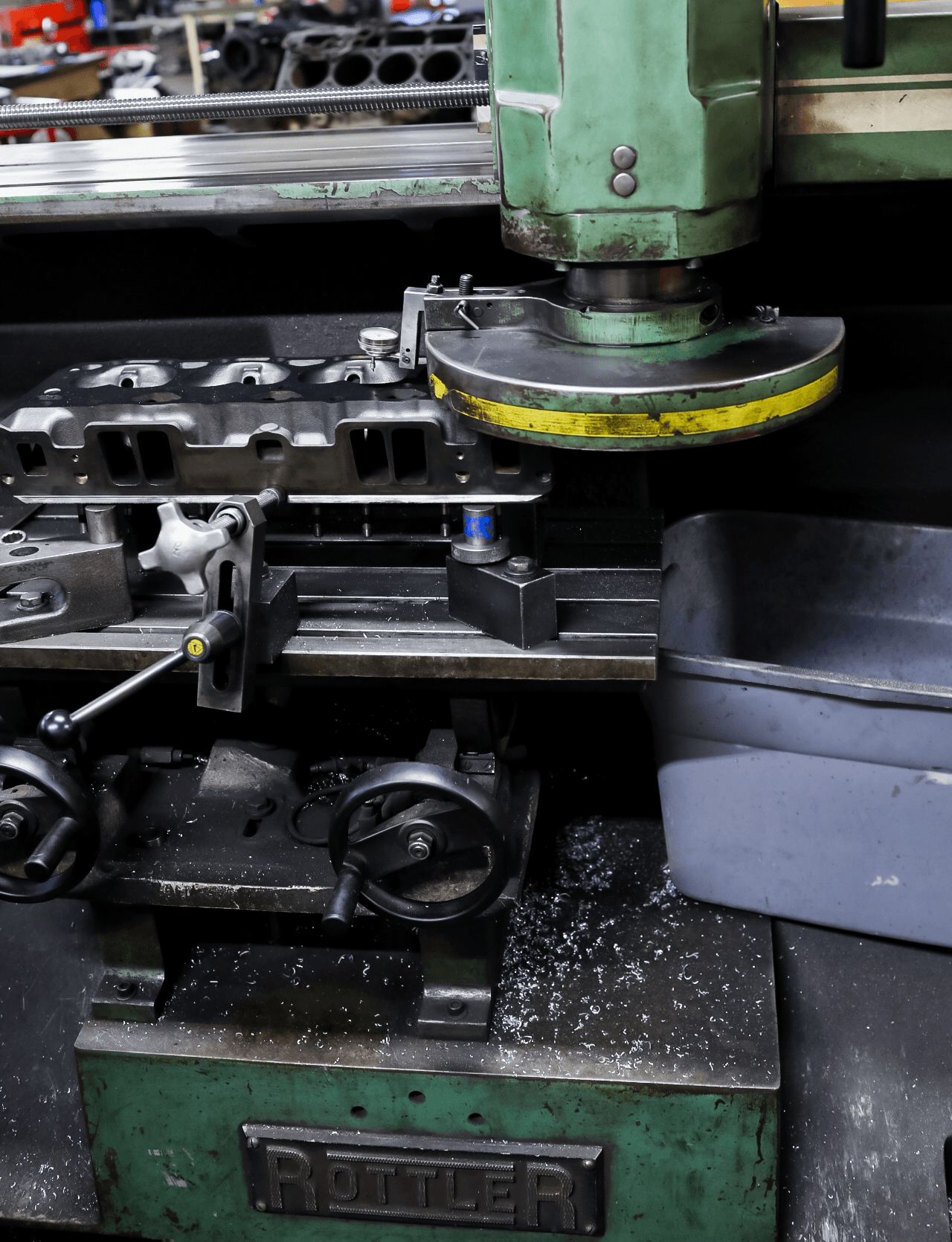

I’m going to start by being blunt: I’m a woman. This may not seem like such a big deal, except that I own an engine shop. Entering into this industry was terrifying. I had been buying, repairing and selling cars for a while before I became an engine shop owner and even selling a car that had an engine built by a woman had proved difficult. Many men, on average, in my area of the country (Arkansas) didn’t trust that an engine built by a petite woman could equal quality. Regardless of the pushback, an opportunity came up to purchase an engine machine shop – and I did! I cleaned out all of my savings and went all in on the engine machine shop, praying that I could earn the respect of the male dominated automotive industry.

As always, we appreciate you sharing your insights and we’ve got a few more questions for you, but before we get to all of that can you take a minute to introduce yourself and give our readers some of your back background and context?

When I was a young girl, my dad implemented a rule that I couldn’t get my drivers license and drive unless I could work on the vehicles myself. My dad was a retired U.S. Army Mechanic, and he was a good teacher.

My first car was a 1966 Ford Mustang (that I still have to this day). That car required a lot of work. Dad and I would work on it, and he taught me everything I needed to know to keep it on the road.

I always enjoyed mechanics, but my parents wanted me to go to college and enjoy an air conditioned career with a six-figure salary. So, that is what I did. I have a degree in Legal Studies and a degree in Psychology.

When covid hit the nation, I lost my dad. Then, two months later my husband and I welcomed our third child. I went on maternity leave and decided to resign from the corporate workforce.

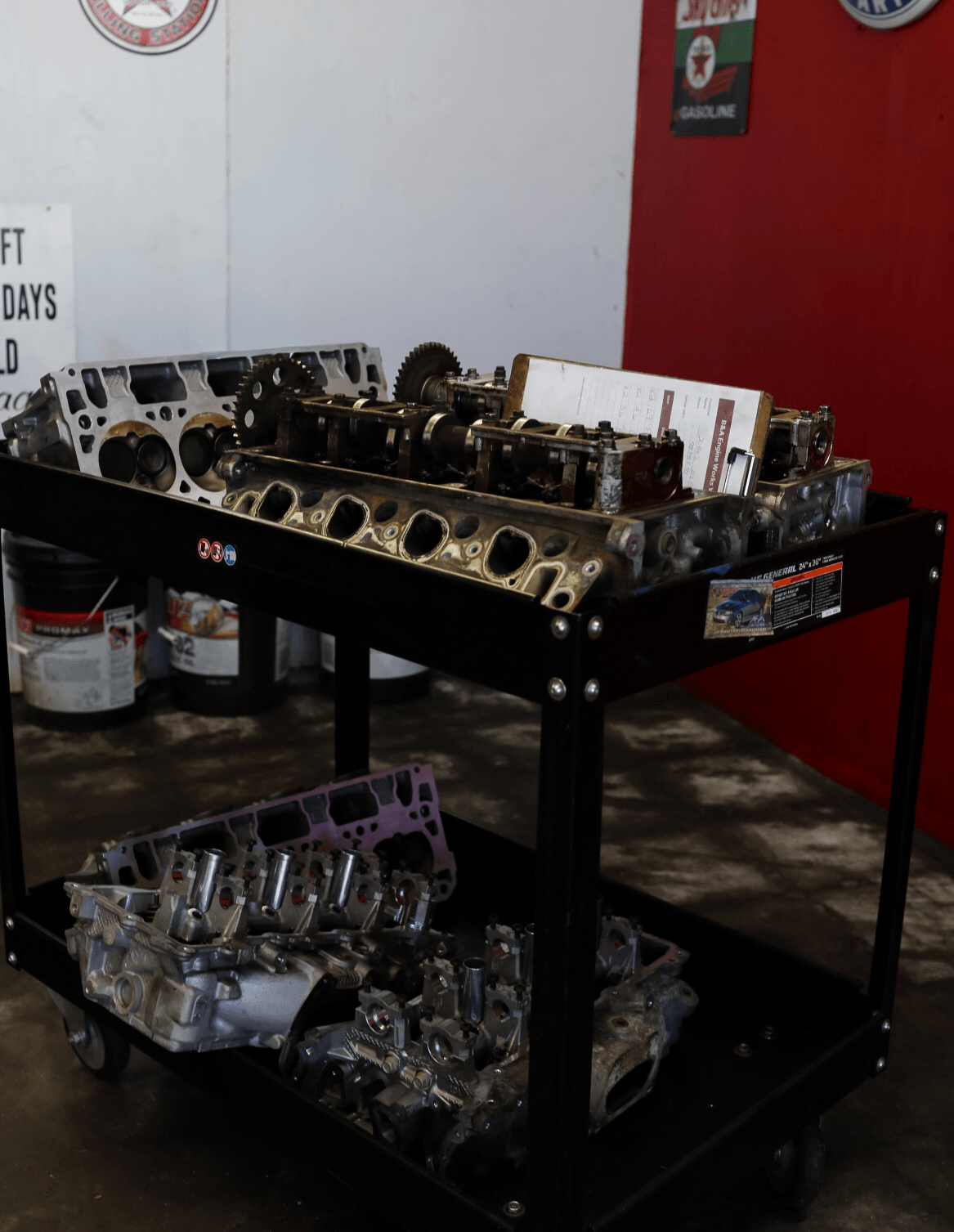

I then began buying cars with blown engines and rebuild them. I would flip a car once every three months out of our home garage. Being in the shop made me feel a strange sense of closeness to my dad.

I used a machine shop in Van Buren, AR for all of my engine machine work, B&A Precision Engine. One day, I went to pick up a set of cylinder heads after getting them resurfaced and the owner of the shop asked me if I wanted to purchase the equipment – all of it. I thought he was kidding but I eventually learned he was in stage 4 cancer and wished to enjoy some retirement until the cancer won the fight. He told me I had 24 hours to think over the opportunity and take-over the lease.

I went home and asked my husband what he thought about the proposal. My husband agreed to support me in the endeavor. I drained all of our savings and bought the machinery. I took over the lease and registered a new name of “B&A Engine Works”. The shop had been associated with the “B&A” name for the last 35 years, and I had no intention of changing a tradition.

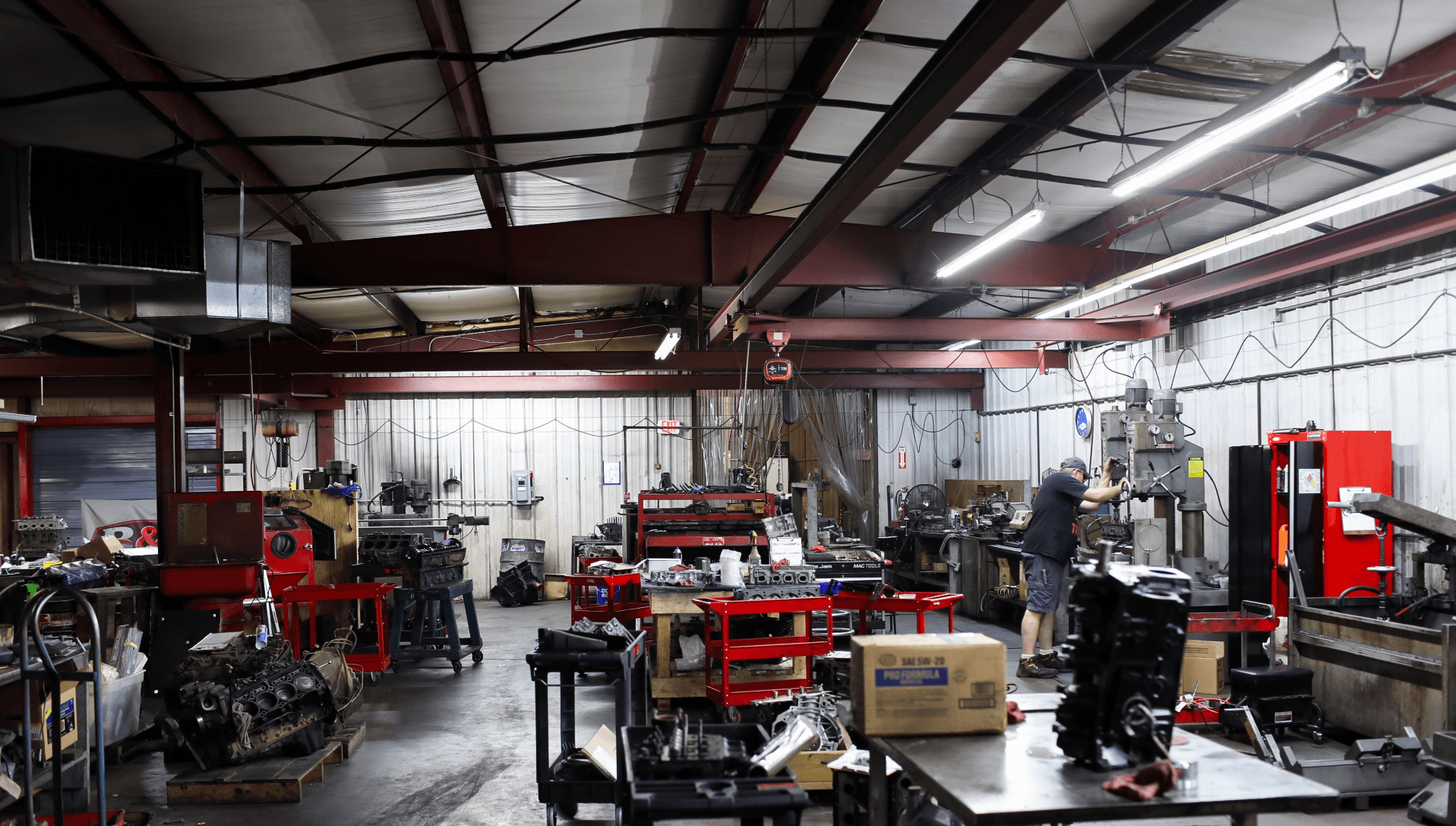

When I finally went back into the shop, as the owner, I realized that it hadn’t changed in 20+ years. I found paperwork/checks/work orders, etc. from the 1980’s. It was dark and dreary. The lighting was mostly out or inoperable, many of the machines hadn’t seen production in 10+ years, and there was a layer of oil at least 1/4 inch thick on all the work benches, the shop was cluttered and disorganized. While trying to keep up the flow of drop-off work, I was also spending my evenings cleaning, repairing and improving. I opened the space up, removed all of the clutter and scrap engine components, repaired the lighting and built out a lobby that was more suitable for work intake.

In the beginning, the shop was only offering cylinder head work (which is all it had offered for the last 10 years); however, there were machines in the shop that were designed for block work. However, looking back on it now, it’s best that it wasn’t a full-build shop at that time. This allowed me to gradually build the service offerings as I was comfortable.

Now, a year and a half later, the shop has went from cylinder head repair/rebuild only to:

Complete Engine Rebuilds

Cylinder Head Resurfacing

Vacuum Testing

Valve Recondition/Replacement

Pressure Test

Magnaflux

Aluminum/Cast Iron Hot Tank

Wrist Pin Removal/Installation

Flywheel Resurfacing

Exhaust Manifold Resurfacing

Intake Manifold Resurfacing

Camshaft Bearing Installation

Bolt Extractions

Engine Block Boring/Honing

Engine Block Decking

Crankshaft Polishing

and soon we will offer crankshaft resizing; as we have just added this machine to our shop!

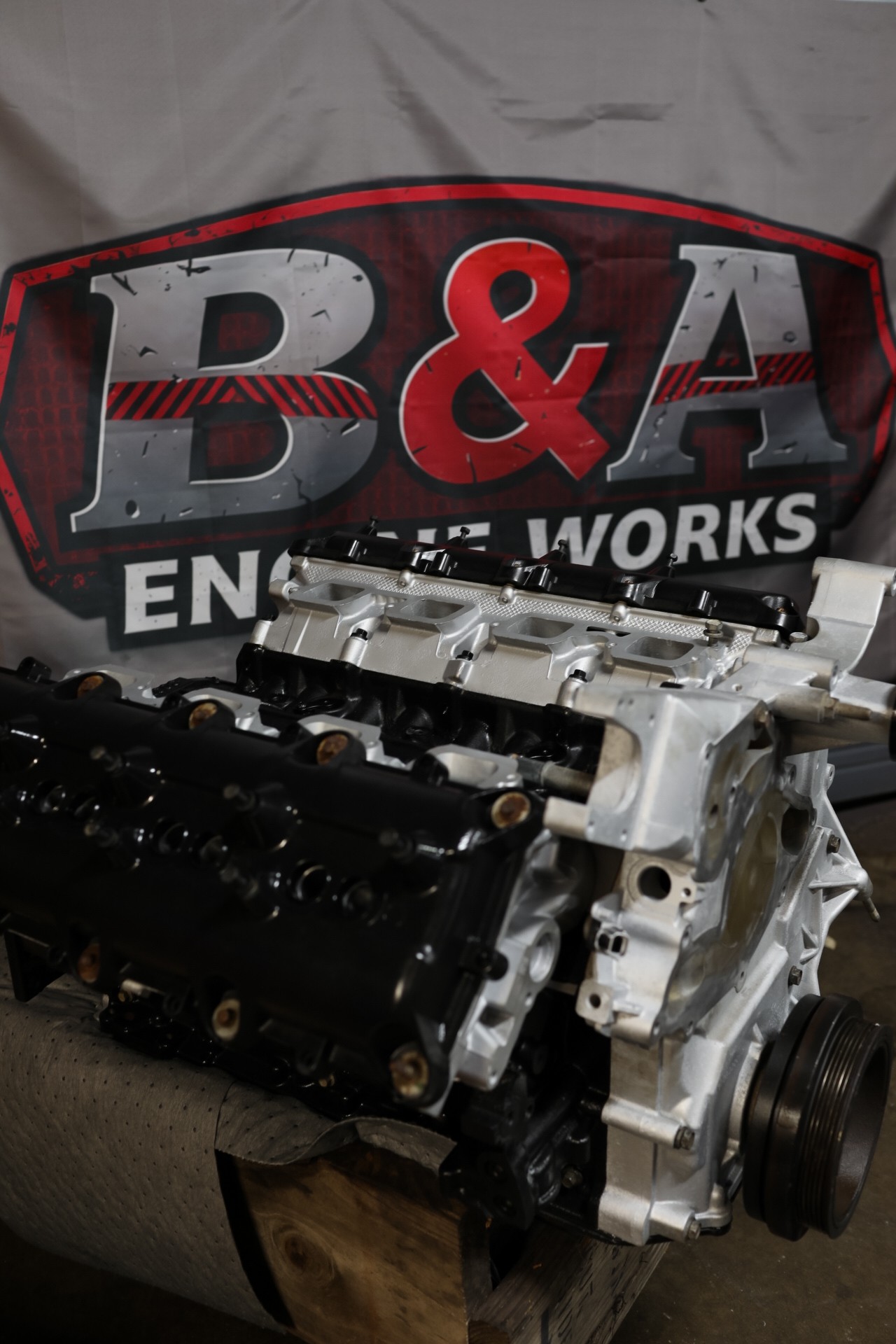

If you have an issue with the mechanical functioning of your engine, we are the solution. We can re-machine your engine to look and perform like its new again (if not better than new!).

The part of B&A that sets us apart from other machine shops, or even repair shops, is that we are friendly. We take the time to explain to you the cause/remedy for the issues you’re experiencing. Many shops will suggest a crate engine when your engine begins showing signs of failure, but we are a strong advocate for repairing what you already have.

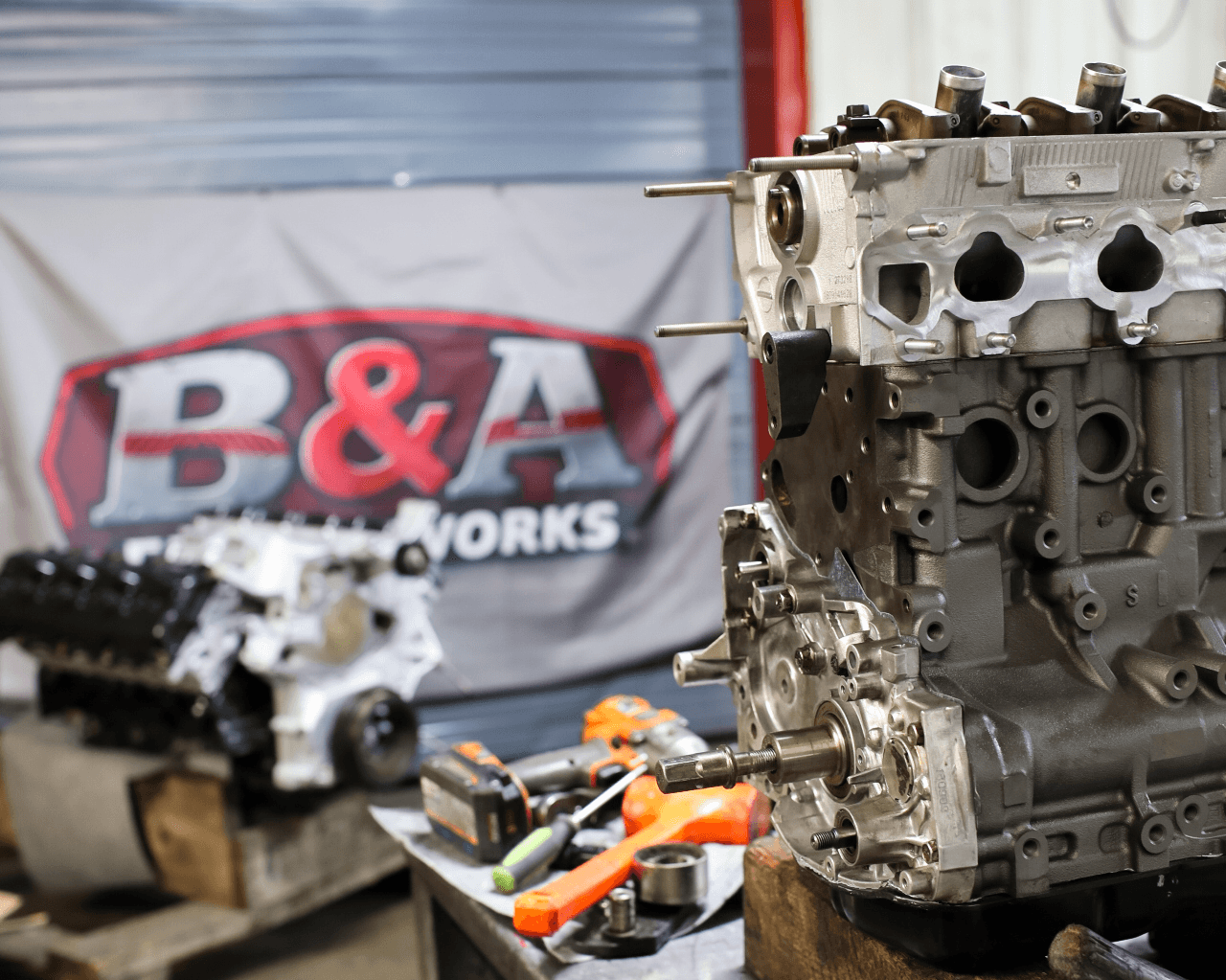

Each and every one of us working in the shop has firsthand knowledge of the inner workings of your engine, and you won’t be bounced between departments. Every engine that comes through B&A is subject to team collaboration and understanding. It’s a personalized approach, and never an assembly line business structure.

Attitude is everything and you’ll find that right attitude at B&A, with a smile and a patient machinist that is willing to explain the whole process to you.

At B&A we don’t extract or install engines, that isn’t our specialty niche. BUT, we do provide you with a rebuild that is machined with precision, and a “baby build book” that documents the whole process for your records. Whether it’s for a show car display, or your daily driver, you’ll have a great conversation piece.

Do you have any stories of times when you almost missed payroll or any other near death experiences for your business?

Toward the beginning of the business, I noticed that work had slowed down drastically. I also noticed that some customers would come in, inquire about the ownership or asked to “speak with the machinist”, and when I would inform them that I was the owner and (at the time) the machinist, they would appear confused, I’d have to explain myself again and then they would take their work elsewhere. I would like to think that these particular customers were simply adverse to change; however, I have a feeling it was because I was a petite woman standing in a man’s role that they didn’t feel I was competent for.

As word got around that the business was sold to “a woman”, business continued to fall. I was getting worried. I had started advertising, boosting online presence, creating a webpage and doing anything I could do to CHANGE my client-base. In my mind, the drop in business was okay. It didn’t mean that the work wasn’t out there, it simply meant that I had to find my own client base as opposed to piggy backing off of the previous business owner’s. Don’t get me wrong, several of the mechanic shops did give me a chance and they continued to use my services – to which, I am forever grateful. In turn, those businesses that continued to utilize my services, ended up providing referrals to new clients! I slowly built my base of customers that didn’t care that I was a woman, or that my cylinder head shelves were pink! I’m still building my base as each month I see sales growing higher and higher.

When we were in the midst of the slow time, I stopped taking pay all together. I paid my three guys, I cut back expenses but I never let the morale of the shop die. I was very transparent with the team as to where we were financially; however, instead of focusing on the doom-and-gloom, we celebrated every day and every completed job. Each week at payroll, I would smile and tell them, “We lived to see another week! Excellent job!” After a time, they began to tell me, “Hey! We lived to see another week!” and now I am responding with “of course we did!”

We had gotten behind on bills; the guys knew it. But, their paychecks continued clearing – as that is my first and foremost payment each week. Payroll MUST clear. I am nothing without my team and B&A would die without them. There was one week that I thought I would have to use my personal savings account to pay payroll. We cut it VERY close, but the business survived, and the work came back before disaster fully consumed us.

I truly feel that morale kept the shop going. Had morale dropped to a low, and had my guys given up, feeling defeated, productivity would have decreased, and we surely would have had to close.

How do you keep your team’s morale high?

My advice on how to best manage your team is not to manage it at all – lead it. The best way to lead a team is by example. I have found that the highest morale is found in teams where they are not pulled or pushed. Consider it the difference between a front wheel drive vehicle, a rear-wheel-drive vehicle and an all-wheel drive vehicle. Your team should function in all-wheel drive, where everyone is working toward the same goal.

I constantly remind my team that THEY are B&A, WE are B&A. The business is not simply – Me. The business is all of us and without any one of them, we would be at a disadvantage.

I never forget to thank them for what they do, because I truly appreciate the hard work they put in. It’s a dirty, hot, and sometimes painful job; yet, they perform flawlessly without complaint. At the end of every week I always recap with them so they know where the business stands – how we are doing.

I never ask anything of any one of my team members that I wouldn’t be willing to do myself. For example, a few months ago we were changing the plastic door curtains between the washroom and the production floor. It’s a 14′ tall opening and I know that one of my team members, Josh, is afraid of heights. He did try to put them up, but once I noticed his struggle and how serious it was, I climbed the ladder myself. Josh assisted in the completion from below. Not once did I tell Josh to try harder, or to push through. I know my team and I respect them not only as workers, but as individuals.

When you work alongside your team, include them in progress AND decisions that would also affect them, recognize their strengths and accomplishments and show respect and appreciation, they’ll be right there with you in all-wheel drive.

Not only does this method of leading your team prove beneficial in running a business, but it raises morale and individual self-esteem. Individual self-esteem is crucial in unlocking your team’s potential. I encourage one of my team members, Steve, regularly. He is our “maybe” guy – as in “maybe I can do it”. He is the best machinist in Arkansas, so of course I have full faith that he could machine the moon if there was a work order for it; but he isn’t always as confident as I am in his abilities. Build up your team members, help them push into unfamiliar territory (but don’t be disappointed if they hit a wall either), growth is sometimes hard – that’s why it’s called “growing pains”.

I end every week on a high note, and even when it’s been a rough week, I let them know that its okay, next week’s schedule looks awesome. So, we just keep on keeping on. For the record, next week’s schedule always looks awesome, even if it doesn’t, because you never know what will walk through the door.

Contact Info:

- Website: https://www.baengineworks.com

- Facebook: https://www.facebook.com/baengineworks/

- Other: TikTok: @cheermommachinist (B&A Engine Works)

Google: https://share.google/gkyKWNEb22kxASeqd

Image Credits

Images courtesy of Kendra Grubb Photography.