We recently connected with Rosemarie and Thomas Cannell and have shared our conversation below.

Alright, Rosemarie and Thomas thanks for taking the time to share your stories and insights with us today. Folks often look at a successful business and imagine it was an overnight success, but from what we’ve seen this is often far from the truth. We’d love to hear your scaling up story – walk us through how you grew over time – what were some of the big things you had to do to grow and what was that scaling up journey like?

In order for us to scale up, we really had to streamline a lot of the processes that we had. We had to invest in new tools, new methods, and new applications, all to make us work more accurately and efficiently.

Having a social media presence and selling on different platforms has also helped us scale up. Since a lot of people shop online now, we make sure to take high quality photos of our products to accurately portray what we are selling or what we have made.

Sometimes people find us through social media and other times we’ve reached out to individuals or businesses. We really try to build good relationships and that was a big part of our expansion in this market. If someone likes the work we’ve done, then they keep coming back for more and they spread the word.

Rosemarie and Thomas, love having you share your insights with us. Before we ask you more questions, maybe you can take a moment to introduce yourself to our readers who might have missed our earlier conversations?

Thomas originally did a carpentry apprenticeship when he finished school, and then trained and worked for a cabinet maker in Newcastle, England. His passion for building kitchens eventually turned into a passion for the culinary arts and working in kitchens. For many years he worked as a chef, but was always doing renovations on our home and building furniture on the side. He eventually wanted to go back into carpentry, and when the pandemic hit that was just all the more reason to start the business.

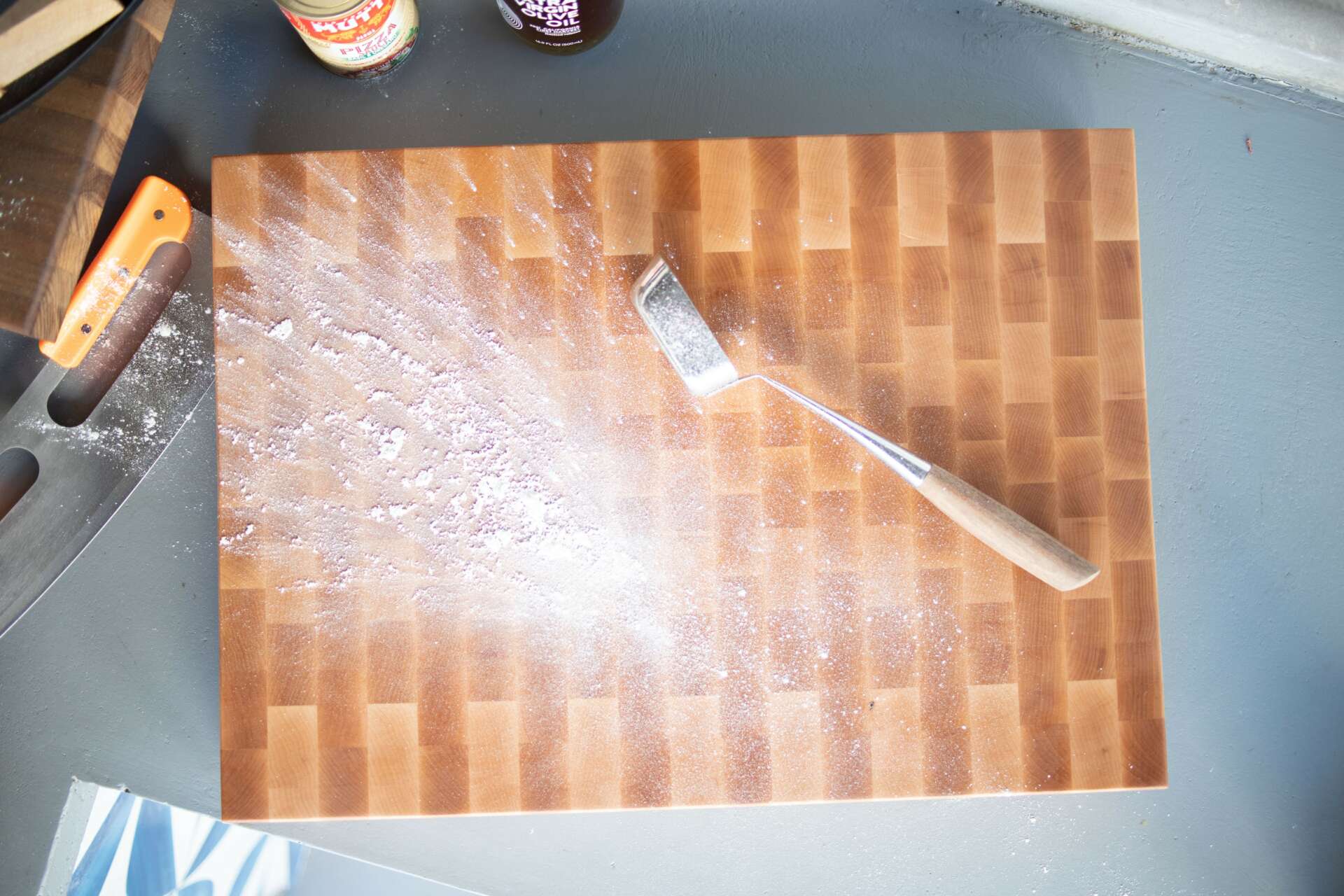

We make various woodworking pieces such as cutting boards, serving boards, and other kitchen and home goods. We also do a lot of bespoke furniture such as dining tables, coffee tables, consoles, and other products.

What sets us apart from others is not only do we design our own pieces, but we also work with clients and try to put their own ideas to fruition. We really try to make unique products and work one-on-one with individuals. We also put a lot of focus on the quality of our products and the details – to how it’s built and the finishes used, and how it’s presented. We want you to look and feel our products, and know it’s well made. We also provide care information and board waxes when customers buy boards from us, and go over care and maintenance as well for some of our furniture pieces.

We do have a new brand coming soon called Tyne Design that will be separating out our furniture and other woodworks. We’re going back to our roots and keeping Block and Bowl for our culinary/kitchen collection. We want to make sure that we target the correct audience for each of our brands, and showcase the products relevant to the name.

Can you talk to us about manufacturing? How’d you figure it all out? We’d love to hear the story.

We manufacture our own products using premium hardwoods from a local family-owned business. We knew how to make some of the products we have from Thomas’ carpentry background, but since we make bespoke pieces sometimes we have to design or think about how we’re going to put someone’s design to reality. We’ve had to make a variety of pieces of different shapes, sizes, and some of our most challenging projects have been larger curved wooden pieces. We’ve tried different methods for each piece depending on what suits it, for example one of our clients wanted a curved hallway console and it was quite a thick and heavy console. We had to use our CNC machine to cut the exact shapes and many layers of it, and then put together 30 pieces of wood for the waterfall sides. Another project that we had that was a fun challenge was a sharp V-shaped bench to go in the corner of a bakery dining area. Rather than using the CNC machine to cut each layer, we had to bend many layers of wood. What we have learned along the way, is there is more than one way to complete a design and we’ve learned which methods are best for different types of projects.

What do you think helped you build your reputation within your market?

Making high quality products built to last, and relationships with local individuals, businesses, and even other woodworkers or local makers helped us build our reputation. We’ve been so fortunate to work with amazing clients and designers who have been repeat customers, or have spread the word and introduced us to other people.

Contact Info:

- Website: www.blockandbowl.com

- Instagram: instagram.com/blockandbowl

- Facebook: https://www.facebook.com/blockandbowl

- Youtube: https://www.youtube.com/channel/UCpp2IH5vE1JiU074PYQ-bdA

- Other: https://www.pinterest.com/blockandbowl/

Image Credits

Rosemarie Cannell