We caught up with the brilliant and insightful Reham Tahir a few weeks ago and have shared our conversation below.

Reham, thanks for taking the time to share your stories with us today How did you come up with the idea for your business?

Palve was never just an idea — it was something that came together naturally, through people who shared the same creative heartbeat.

It really began with Harris Faisal and Anum Zafur. The two were already collaborating — Harris, a visionary creative director with a sharp eye for design, and Anum, a talented textile designer with a gift for texture and storytelling through fabric. Together, they were experimenting with unique pieces that blended culture, craftsmanship, and modern aesthetics.

When I first saw what they were creating, I immediately felt connected to it. Coming from a family manufacturing background, I had always been surrounded by fabrics, production, and the rhythm of creation — but I wanted to build something that carried meaning. Something that celebrated both artistry and identity.

When we met, it just clicked. Their creativity and design sensibility perfectly complemented my market knowledge and experience in manufacturing. We each brought something different to the table — Harris’s direction and vision, Anum’s technical craft and fabric innovation, and my understanding of how to bring ideas to life and into the market.

That’s how Palve was born — a brand built on the balance between creativity, craftsmanship, and commerce.

From day one, our mission was clear: to create pieces that represent the South Asian community in a modern, global way while reviving the artisanal techniques that were slowly fading due to mass production and technology. Palve became a way for us to tell stories — through silhouettes, textures, and details that speak to where we come from and where we’re headed.

At its heart, Palve is more than fashion — it’s a bridge between tradition and modernity, between artistry and accessibility. Every piece we make is rooted in culture but designed for today’s world.

As always, we appreciate you sharing your insights and we’ve got a few more questions for you, but before we get to all of that can you take a minute to introduce yourself and give our readers some of your back background and context?

It really came together when I connected with Harris Faisal, who’s now our Creative Director. Harris had already been creating these standout pieces — designs that carried emotion and cultural depth but still felt elevated and modern. Around that time, he was working closely with Anum Zafur, an incredible textile designer who has such an instinctive understanding of textures and how to make fabric tell a story. When I met them both, it just clicked.

We realized that between the three of us, we had the perfect balance — Harris’s creative direction, Anum’s technical artistry, and my market knowledge and manufacturing background. That blend of creativity, craftsmanship, and strategy became the foundation of Palve.

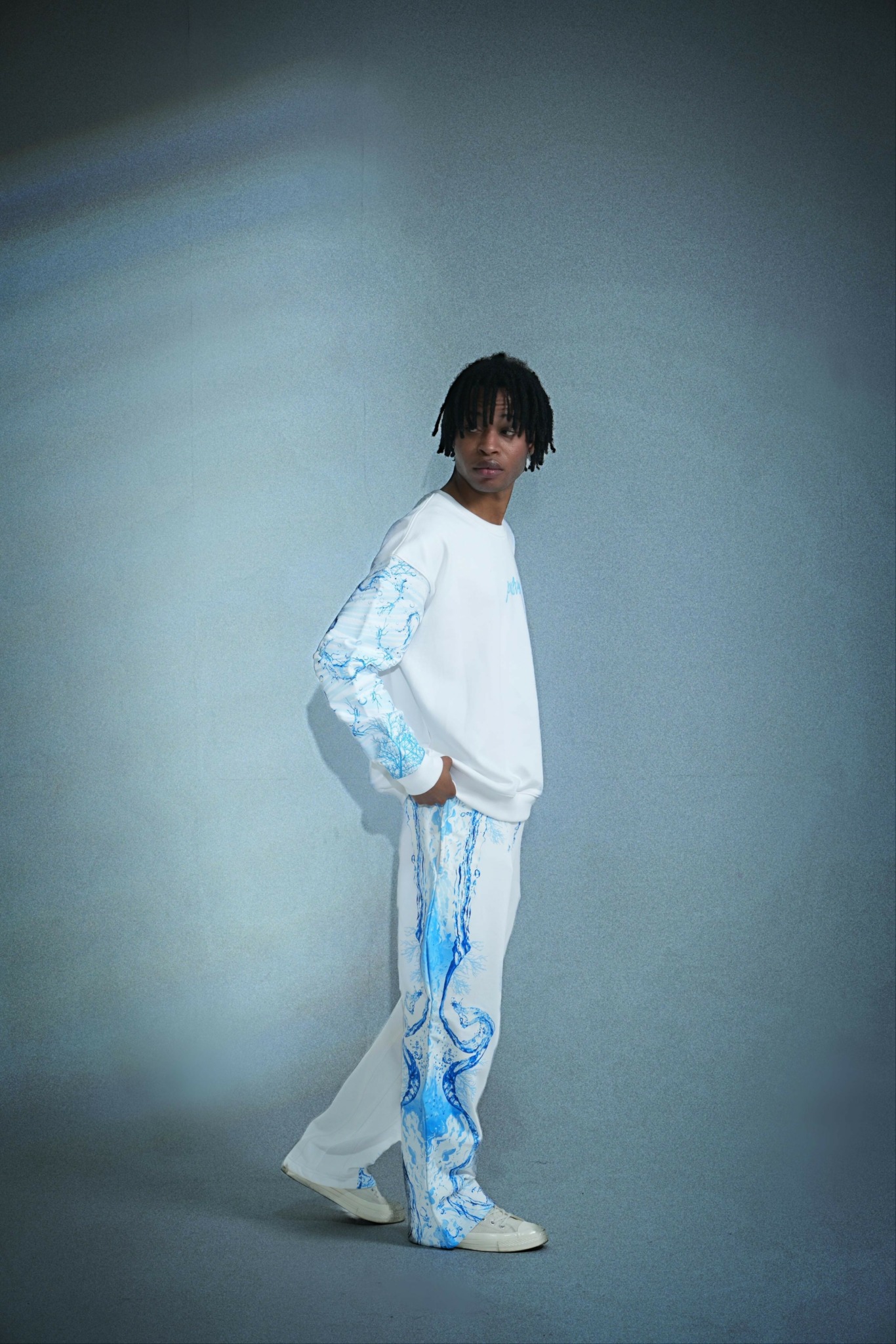

At Palve, we create premium, minimal streetwear — pieces that are rooted in culture but designed for the modern world. Our goal has always been to represent the South Asian community in a new light — not through clichés or nostalgia, but through design that feels global, confident, and refined.

We also focus on something I think a lot of brands overlook — preserving craftsmanship. With the rise of mass production and tech-enabled manufacturing, so many traditional artisanal techniques are disappearing. We want to bring that human touch back into fashion — through carefully crafted details, textures, and silhouettes that carry meaning.

What sets Palve apart is our authenticity. We don’t chase trends. We build stories. Every piece we design comes from a place of purpose — whether it’s inspired by cultural motifs, personal experiences, or the evolving identity of South Asian creatives around the world.

Honestly, what I’m most proud of is how far we’ve come organically. Seeing people across the world connect with our story — not just wearing our pieces, but feeling what they stand for — that’s the most rewarding part.

We’d really appreciate if you could talk to us about how you figured out the manufacturing process.

Yes — we actually manufacture all of our products ourselves. That’s one of the biggest things that sets Palve apart. Unlike many brands that outsource production, we have our own in-house manufacturing facility and team. That gives us a level of control and precision that’s hard to achieve when you’re relying on outside vendors.

Coming from a family manufacturing background, I was already familiar with the entire process — from sourcing fabrics and managing production timelines to quality control and finishing. So when we started Palve, it felt natural to bring that experience into our own setup rather than hand it off to someone else.

Having our own facility allows us to be completely hands-on with every piece. Harris and Anum work closely with our production team to translate their creative ideas directly onto the fabric — no middlemen, no creative dilution. If something needs to be adjusted — whether it’s a stitch line, a dye tone, or the drape of a fabric — we can test, refine, and perfect it right there on the spot.

It’s definitely been a learning curve, even with experience. Running your own production means you’re responsible for everything — the good and the bad. You quickly learn the importance of timelines, material sourcing, and maintaining consistency at scale. But the biggest lesson has been that manufacturing is an art in itself. When you understand the process deeply, you’re able to innovate more confidently because you know what’s possible and what’s not.

Can you share a story from your journey that illustrates your resilience?

Definitely — I think resilience has been one of the biggest constants in our journey with Palve.

One story that stands out is from our early production days. We were still refining our first collection, and because we manufacture everything ourselves, every little detail — from stitching to fit to fabric finishing — was in our hands. There was one particular drop that we were really excited about; it was meant to set the tone for Palve’s identity. But right before launch, we realized the entire batch didn’t meet the standard we wanted. The stitching tension was slightly off, the fabric drape wasn’t flowing how we envisioned, and it just didn’t feel right.

For a small brand, that kind of setback can be tough — financially, mentally, and emotionally. We had already invested time, resources, and energy into it. But instead of compromising or rushing to release, we made the hard call to redo everything. We went back to the drawing board, tested new materials, and restructured our production flow. It delayed the launch, but it also set the tone for how we would operate as a brand — quality over convenience, always.

That moment taught us what resilience really means. It’s not just pushing through challenges — it’s staying true to your standards even when it costs you something.

There have been plenty of other moments too — from navigating international logistics to dealing with fluctuating material costs — but that early setback shaped how we approach every decision now. We learned that growth takes patience, and that resilience isn’t about speed; it’s about staying aligned with your purpose.

Looking back, I’m grateful we made that choice. It’s the reason people trust Palve today — because they can feel that every piece was made with intention and integrity.

Contact Info:

- Website: https://www.palve.shop

- Instagram: @palveofficial_

- Facebook: Palve