Alright – so today we’ve got the honor of introducing you to Paul Dufour. We think you’ll enjoy our conversation, we’ve shared it below.

Paul, appreciate you joining us today. Can you talk to us about a risk you’ve taken – walk us through the story?

Leaving a stable career to build bamboo fly rods full-time felt like jumping into a river without checking the water temp. I’d been making rods in my free time for years—late nights in the shop, weekends at fishing events—but there was always that “safe” backup plan of a steady paycheck.

The turning point came when I realized that every time I sat down to work on a rod, I lost all track of time. I’d go from splitting cane to tying silk wraps in what felt like minutes, only to look up and see it was 2 a.m. That’s when it hit me: this wasn’t just a hobby—it was my calling.

The risk? Giving up that secure job, steady income, and benefits to launch PJ’s Fine Bamboo Rods as a full-time business. I had no corporate safety net, no “Plan B” beyond making the absolute best rods I could and trusting that anglers would connect with them. I remember thinking, If I’m going to fail, I want it to be doing something I love.

The first few months were equal parts exhilarating and terrifying. I was learning how to run a business while still trying to perfect my tapers, finish my orders, and show up at events to meet customers face-to-face. But little by little, the rods started selling—not because I had the fanciest marketing plan, but because each one carried my name, my hands, and my heart in it. Word-of-mouth spread. Anglers started sending me photos of their PJ’s rods catching trout in Montana, tarpon in Florida, and grayling in Alaska.

How did it turn out? Well, I’m still here—still making rods, still loving every single moment I get to connect with this community. The risk paid off in ways I never imagined. I traded “job security” for life satisfaction, and I wouldn’t go back for anything.

As always, we appreciate you sharing your insights and we’ve got a few more questions for you, but before we get to all of that can you take a minute to introduce yourself and give our readers some of your back background and context?

I’m Paul “PJ” Dufour, founder and head Rodsmith at PJ’s Fine Bamboo Rods in Pagosa Springs, Colorado. My journey into this craft started the way a lot of good fishing stories do—on the water. I was hooked (pun intended) not just on the fishing, but on the tools that connect us to the river. When I cast my first bamboo fly rod, something clicked. The rhythm, the flex, the way the rod came alive in my hand—it was unlike anything I’d felt before. That moment sent me down the rabbit hole of learning to build them myself.

At PJ’s Fine Bamboo Rods, we handcraft custom bamboo fly rods from a single culm of genuine Tonkin bamboo. Every rod goes through over 200 steps—hand-splitting, planing, wrapping, finishing—until it’s a functional piece of art. We also carry handcrafted angling-inspired artwork from other artisans, like Martin Gerdin’s glass trout.

One of my greatest passions is keeping this centuries-old craft alive through our bamboo fly rod building classes, hosted right here in Pagosa Springs. These classes give anglers the chance to spend a week in our shop, learning every step of the process, and walking away with a rod they’ve built with their own two hands. It’s more than just a class—it’s a way to connect people to the history, patience, and artistry of bamboo rod making. Watching someone cast their first self-made bamboo rod is pure magic.

What sets us apart isn’t just the craftsmanship (though we’re pretty obsessive about that)—it’s the way we connect with our clients. We’re not just handing over a rod; we’re building something that will hold memories for decades. I love hearing from customers who send photos of their rods in action from all over the world, or who bring their kids in to learn about bamboo rod-making.

The problem we solve is pretty simple: in a world of mass production, we bring anglers back to something authentic. Bamboo rods aren’t just fishing tools—they slow you down, make you more intentional, and connect you to a tradition that spans generations.

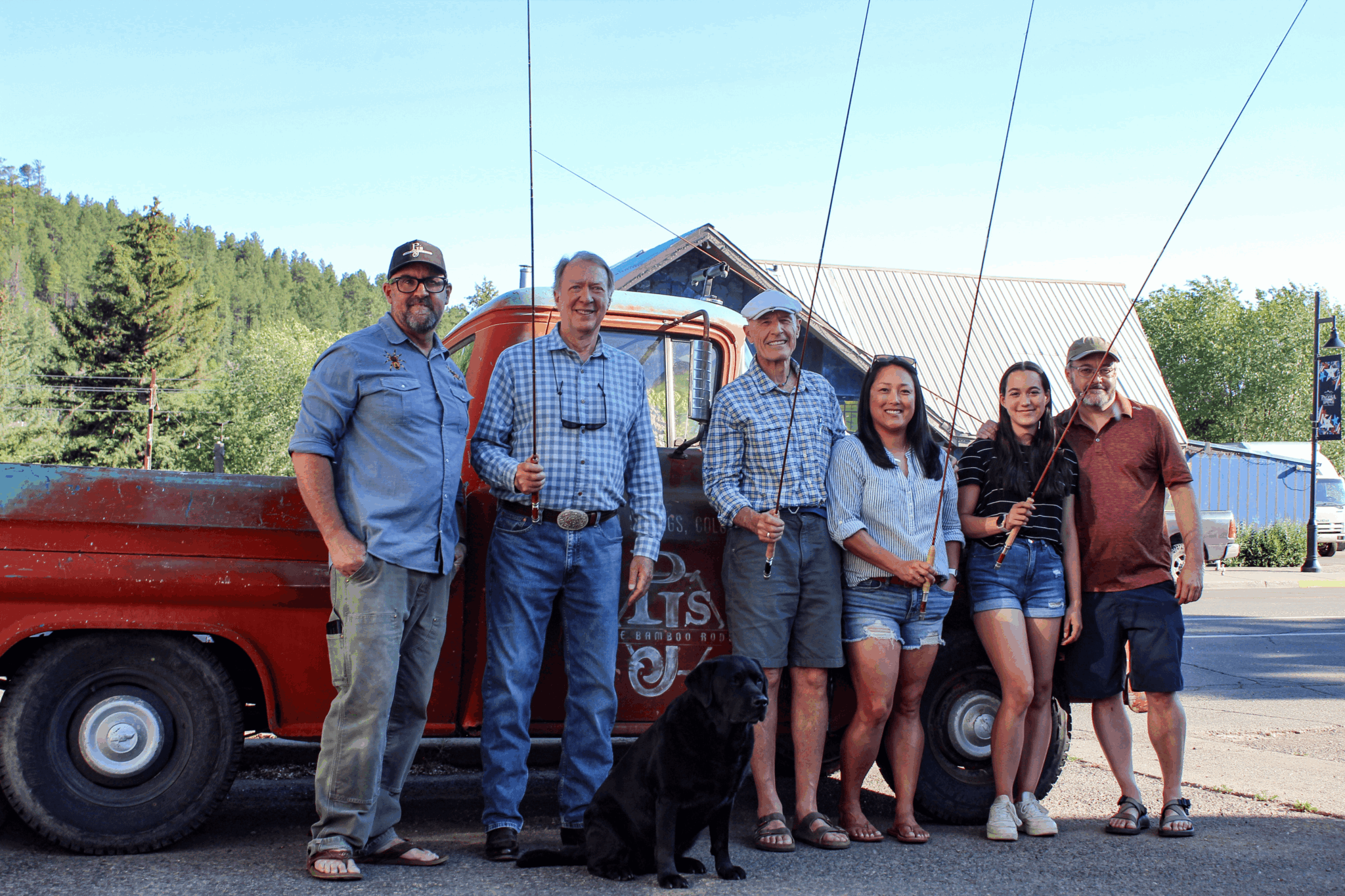

What I’m most proud of is the community that’s grown around PJ’s. Many clients become friends, and some even return for our classes just to make their own heirloom. That connection—to craft, to the water, and to each other—is what this business is really about.

If there’s one thing I want people to know about PJ’s Fine Bamboo Rods, it’s that every rod has a story, and yours is just waiting to be written on the water.

We’d really appreciate if you could talk to us about how you figured out the manufacturing process.

Yes—we make every single bamboo fly rod in-house, right here in Pagosa Springs. Our “factory” is our workshop, and our machines are our hands, planes, and a whole lot of specialized tools built for one purpose: turning a single culm of Tonkin bamboo into a rod that will last generations.

When I started, I didn’t know all the steps—it’s not like you can walk into a big-box store and buy a “Bamboo Rod Making for Dummies” kit. I learned through a mix of mentorship, research, trial-and-error, and hundreds of hours at the workbench. My early rods taught me as much about patience as they did about craftsmanship. Each mistake became a masterclass: a glue line that didn’t set right, a wrap that frayed at the last second, a finish that bubbled in the final coat. You can’t outsource that kind of learning.

We never looked for a vendor to manufacture for us—because outsourcing would erase the soul of what we do. Every PJ’s rod is hand-split, hand-planed, and wrapped in-house, so we can control every variable from node stagger to final buffing. That’s what gives our rods their unique action and character.

One of the biggest lessons I’ve learned is that manufacturing something by hand at this level is as much about discipline as it is about skill. It takes over 200 individual subtle steps to build a bamboo fly rod, and if you rush any one of them, the entire rod can be compromised. Quality is never accidental—it’s the result of doing the right thing, the right way, over and over again.

I’ve also learned that manufacturing isn’t just about producing a thing—it’s about producing a feeling. When someone picks up one of our rods for the first time and says, “Wow, this feels alive,” that’s when I know we’ve done it right.

How’d you build such a strong reputation within your market?

From day one, I decided that if a rod left my shop, it had to be something I’d be proud to fish for the rest of my life. That standard meant turning away shortcuts, rejecting anything that didn’t feel “just right,” and obsessing over the details—down to the silk wrap tension and the perfect ferrule fit. People notice that. When an angler picks up one of our rods and it casts like a dream, that experience speaks louder than any ad campaign ever could.

The second piece is connection. I spend time with my clients—on the phone, in the shop, at the Fly Fishing Show—listening to what they want, swapping fishing stories, and making sure their rod feels like it’s truly theirs. That personal touch doesn’t just sell rods; it builds trust and turns customers into friends.

Word-of-mouth has been the biggest driver of our reputation. When someone loves their rod so much they bring it to the river and tell every angler who asks about it, that’s marketing money can’t buy. Add in our bamboo rod-building classes here in Pagosa Springs—where people get to be part of the craft themselves—and suddenly, we’re not just selling a product, we’re sharing an experience.

In short: make something exceptional, treat people exceptionally, and your reputation will follow you upstream.

Contact Info:

- Website: https://pjsfinebamboo.com

- Instagram: https://www.instagram.com/pjsfinebamboo

- Facebook: https://www.facebook.com/pjsfinebamboo

- Linkedin: https://www.linkedin.com/company/pj-s-fine-bamboo-rods

- Twitter: https://x.com/pjsfinebamboo

- Youtube: https://www.youtube.com/@pjsfinebamboo

- Yelp: https://www.yelp.com/biz/pjs-fine-bamboo-rods-pagosa-springs?osq=Pjs+Fine+Bamboo+Rods

Image Credits

In Focus Photo Co.