We caught up with the brilliant and insightful Nat Harrington a few weeks ago and have shared our conversation below.

Alright, Nat thanks for taking the time to share your stories and insights with us today. How did you come up with the idea for your business?

Initially, Nat’s Nuts was a joke made with a college suitemate. I mentioned that no one sold cinnamon roasted almonds at a local market, and he said, “well, you’ve got the perfect name to make them and sell them… Nat’s Nuts.” A year later, I was fundraising for a missions trip to Guatemala, and thought it would be fun to make and sell nuts for the fundraiser. I bought a handheld roaster, experimented with a few recipes, and from the college dorm kitchen, Nat’s Nuts was officially born.

Great, appreciate you sharing that with us. Before we ask you to share more of your insights, can you take a moment to introduce yourself and how you got to where you are today to our readers.

I’ve always had the entrepreneurial bug, and I’ve always been fascinated by making and selling things. One of my earliest “business ventures” was during a family camping trip as a kid, when I set up a table at the front of our site and sold what could only be described as the most confusing combination of products: homemade lemonade and red-backed salamanders. My brother and I would forage in the woods, and since we weren’t allowed to keep salamanders as pets, we decided to sell them, alongside the lemonade, for $1 to anyone kind enough to entertain our pitch.

That spirit carried into my college years, where I tried just about every hustle I could think of. I fixed phone screens, hosted trivia nights, and sold shoes on eBay. What I loved wasn’t just the challenge of selling, it was the joy of creating things that people actually wanted. Even as a teenager, I was building little inventions just for the fun of it, like a string-and-pulley contraption to turn my bedroom lights on and off, or a locker rigged with a car battery and power inverter so I could enjoy warm nacho cheese between classes.

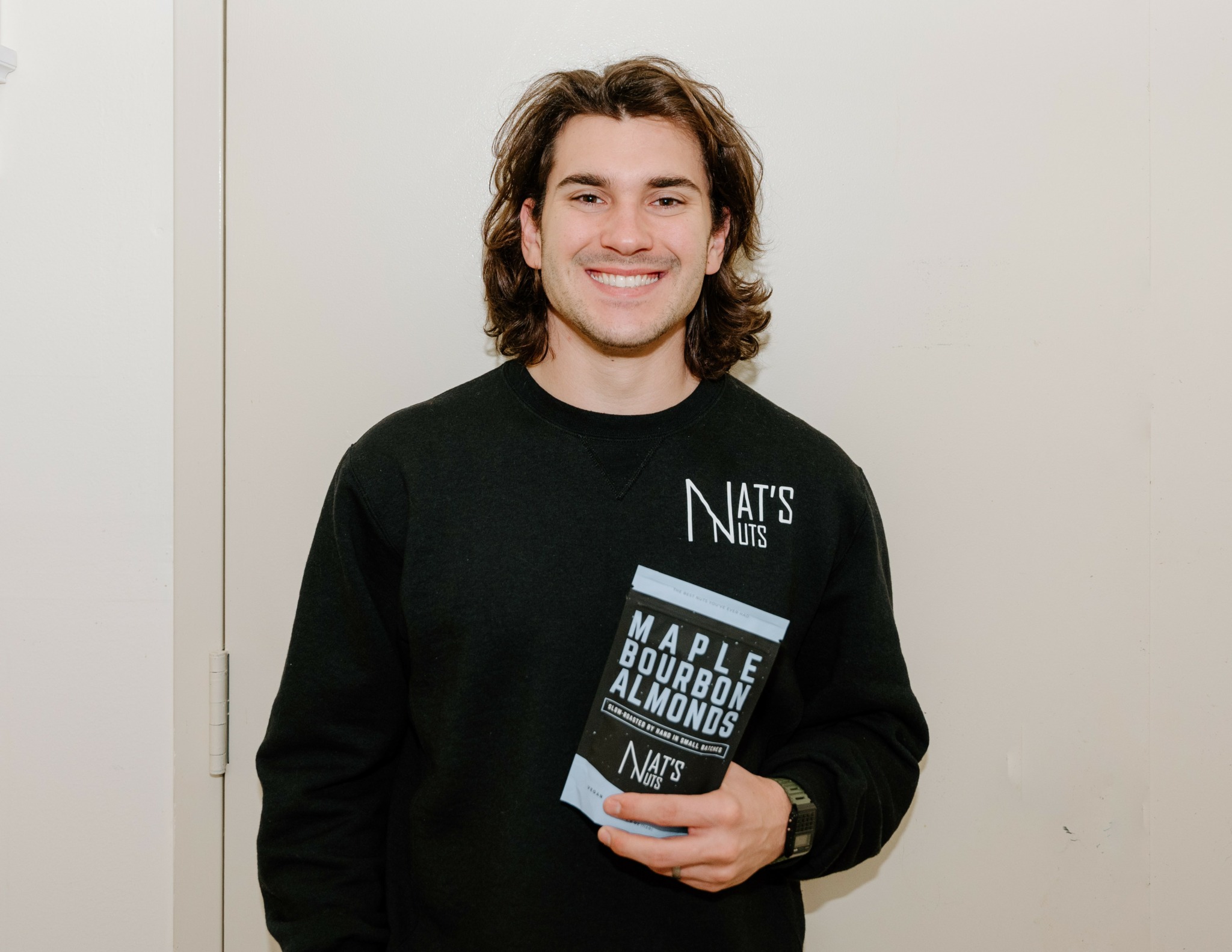

So when the idea for Nat’s Nuts came along, it felt like the perfect intersection of creativity, entrepreneurship, and the chance to improve a real manufacturing process. What began as a dorm room business quickly grew into an international nut roasting operation. Today, we’re proud to still roast every batch by hand, even as our reach has expanded around the world.

At Nat’s Nuts, we don’t take ourselves too seriously, but we take our product and customer service with the utmost care. All of our nuts are certified gluten-free, made with simple, pronounceable ingredients, and offer a healthier alternative to overly processed snacks, without ever sacrificing flavor or fun.

What I’m most proud of, though, is the opportunity to build a company that supports people. We pay our team above-average wages, and encourage them to put family first, even before the business. I started Nat’s Nuts with the goal of creating something meaningful, and supporting others has always been, and always will be, the cornerstone of what we do.

Can you talk to us about manufacturing? How’d you figure it all out? We’d love to hear the story.

Yes, we’ve always manufactured our own product, which is actually pretty unique in the food world. A lot of snack brands outsource production early on, but for us, keeping everything in-house has always been part of our DNA. It started very humbly, our very first batches were roasted in a little four-cup handheld roaster. From there, we graduated to twenty-quart pots on a stovetop, then to a converted concrete mixer, which, believe it or not, actually worked really well for small-scale nut roasting.

Today, we’ve grown into an industrial warehouse with larger-scale equipment, but we still hold on to the same principles we started with. Every batch is roasted by hand, and we maintain control over every part of the process. That’s been important to us not just for consistency and quality, but also for innovation. When you’re hands-on with manufacturing, you learn the quirks of your product inside and out, and that gives you a kind of flexibility you just don’t get when you outsource.

Along the way, we’ve learned that manufacturing is all about problem-solving and constant improvement. Early on, we had to get really creative with limited resources, like turning that concrete mixer into a roaster, but those challenges taught us resilience and how to think differently about equipment and processes. Even now, at a larger scale, the mindset is the same, we’re always tweaking, refining, and finding ways to get better.

In the end, keeping manufacturing in-house has been one of the biggest factors in what sets Nat’s Nuts apart. It lets us stay true to our values of quality, freshness, and craft, while also giving us the freedom to experiment and grow on our own terms.

How do you keep in touch with clients and foster brand loyalty?

We keep in touch with our customers through a monthly “Nutletter,” where we share business updates, nut facts, insider info, and fun content that gives people an authentic, behind-the-curtain look at how Nat’s Nuts operates. It’s our way of inviting customers into the story of the business, not just selling them a product.

We’ve also recently started using social media more intentionally to show the day-to-day operations, the people behind the brand, and the story of how we do what we do. By being transparent and authentic, we give our customers a real connection to Nat’s Nuts, which helps build trust and lasting loyalty.

Contact Info:

- Website: https://www.natsnuts.com

- Instagram: https://www.instagram.com/nats_nuts/

- Facebook: https://www.facebook.com/natsnutsofficial

- Linkedin: https://www.linkedin.com/company/natsnuts/