We’re excited to introduce you to the always interesting and insightful Michelle Nguyen. We hope you’ll enjoy our conversation with Michelle below.

Alright, Michelle thanks for taking the time to share your stories and insights with us today. What was it like going from idea to execution? Can you share some of the backstory and some of the major steps or milestones?

I’ve been a lash artist since 2008 and have worn lashes myself for over a decade. But a few years ago, I developed an allergy to traditional lash glue. It was frustrating. I had spent my entire career in the lash industry, and suddenly, I couldn’t wear the very thing I loved. Because I’m sensitive to a lot of products, I turned to cluster lashes as a gentler alternative. But they weren’t perfect either: they were uncomfortable, stiff, and just didn’t feel like something I would want to wear every day.

That’s when the idea hit me: what if I could create a better version of the cluster lash? One that was more comfortable, lighter, and actually felt wearable. That was the moment TAD was born, not as a business yet, but as a concept.

Because I had been working in lash manufacturing since 2019, I actually own 5 Lash Manufacturers in Vietnam, I felt confident. Up until that point, there hadn’t been a lash design I couldn’t bring to life. So I thought this would be easy.

It wasn’t.

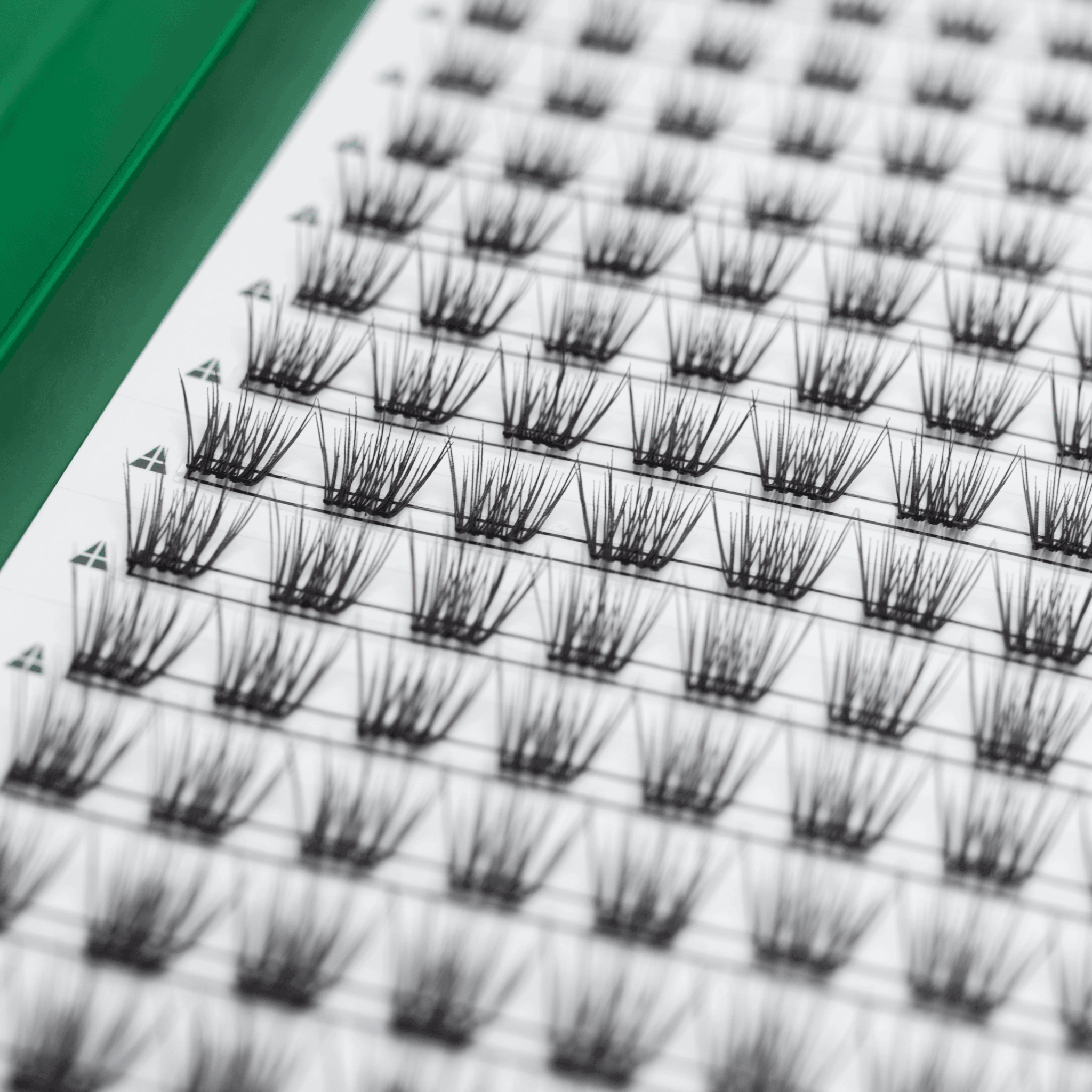

I had this vision in my mind, a lash cluster that would mimic the soft hold of velcro, with tiny micro-arms that could gently wrap around the natural lash. But no matter what we tried — new molds, softer fibers, custom designs — nothing worked. It felt impossible.

That’s when I started exploring 3D printing. I spent months researching and interviewing five different 3D printing companies across the U.S., and every one of them said the same thing: it couldn’t be done. The lashes were too small. The detail was too intricate. Impossible to print in MASS quantities.

Then I found OPT, a microprinting company in Boston that specialized in exactly the kind of precision work I needed. I flew out to visit them, and we started experimenting. What followed was a year and a half of relentless iteration — 108 different material formulations, thousands of prototypes, and countless hours at the drawing board.

All of that was just to create one lash style, the one I named DREAM. And it truly was. DREAM was the proof that innovation in beauty doesn’t have to come from a massive company, it can come from someone who deeply understands the product, the customer, and the pain points.

That was how TAD went from idea to execution: out of necessity, a refusal to settle, and a passion for better beauty. Once I held the final prototype in my hand, soft, flexible, lightweight, and made right here in the USA, I knew we were ready to launch. And from there, the brand took off.

Awesome – so before we get into the rest of our questions, can you briefly introduce yourself to our readers.

For those who don’t know me, my name is Michelle Nguyen, and I’ve been in the beauty industry since 2008, when I became a lash artist shortly after moving to the U.S. for college. I opened my first salon in 2016, focusing exclusively on lashes and nails. That experience opened the door to teaching and training other lash artists, and eventually led me into product development.

In 2017, I began sourcing my own private label products to reduce costs for my salon team and students. What started as a side project quickly grew into something more. In 2018, I officially launched PLA Pro, selling just a few packages out of my parents’ garage. By 2019, I had opened my own lash manufacturing facility back home in Vietnam, and by summer 2020, PLA really took off, thanks to our now-signature product: PLA ProMades.

My passion has always been rooted in solving problems for beauty professionals. As a lash artist myself, I understand what’s frustrating, what’s missing, and what’s possible. Product development is truly my favorite part of what I do. I’m proud to say that my sister and I have invented many of the ProMade innovations used by lash artists today.

That same problem-solving mindset carried over into our nail line, born out of the challenge I had in my salon of trying to find the right polish shade in a sea of black bottles. PLA was the first U.S. company to launch a full polish line where the bottle color actually matches the polish inside. It’s beautiful, but more importantly, it makes nail techs’ lives easier.

Our wax line was created for a similar reason. I have extremely sensitive skin and could never get waxed without a breakout. So we created one of the highest quality professional waxes in the industry, formulated specifically for sensitive skin like mine.

Today, PLA Pro is a full-service professional brand, offering lash extensions, nail supplies, and wax products. We’ve come a long way from my parents’ garage, we now operate out of a 70,000 sq. ft. warehouse and HQ in Reno, Nevada.

TAD, our consumer-facing brand, was born out of another personal need. I developed an allergy to lash extension adhesive, which meant I could no longer wear what I’d loved for so many years. That led me to develop TAD’s 3D-printed cluster lashes, a completely unique solution created through relentless testing and cutting-edge technology. The same passion and experience that helped build PLA fuels TAD. My goal isn’t just to sell products, it’s to invent things that have never been done before.

At the heart of everything I create is one goal: to make beauty easier, smarter, and more inclusive. Whether it’s a lash artist working with clients or someone doing their lashes at home, I want our products to feel like a game-changer.

How did you put together the initial capital you needed to start your business?

When I started my business, I didn’t raise money or take on investors. I took $10,000 from my personal savings. Every dollar we made in those early days went right back into the business. We didn’t splurge, we didn’t scale too fast, and I didn’t take a paycheck for the first three years. Even when I did start taking a draw, it was a very modest amount.

We worked out of my parents’ garage for two years before we ever even thought about investing in a commercial building. Reinvesting everything allowed us to build a strong foundation. When we finally found the perfect building, we were in a position to buy it outright, which opened the door for us to expand not just our operations, but into real estate.

The biggest mistake I see new business owners make is taking money out too early. It’s exciting when the money starts coming in, but pulling cash out too soon stunts your growth. You need that capital to invest in inventory, systems, talent, and infrastructure. And you need to have enough set aside for when things go sideways, or when the right opportunity comes along.

I built my companies with patience, discipline, and a long-term mindset. I truly believe that reinvesting in your business, over and over again, is the key to sustainable success.

Can you talk to us about manufacturing? How’d you figure it all out? We’d love to hear the story.

Yes, we manufacture our own products, and it’s one of the things I’m most proud of. I own and operate five manufacturing facilities in Vietnam and employ over 700 women. Building these facilities from the ground up is one of my greatest accomplishments, not just professionally, but personally as well.

When we first started, we knew how to make lashes, but not at scale. I launched my first facility with just 12 employees. From there, we built systems, training protocols, and quality control processes that allowed us to scale without compromising our standards. That’s something I’ve never been willing to do — compromise.

If there’s one lesson I’ve learned about manufacturing, it’s this: it’s never as easy as you think it’s going to be. There are always unexpected challenges, supply chain delays, labor shortages, quality issues, but the key is to stick to your vision and never lower your standards for speed or convenience. If something takes longer to get right, let it. Rushing will cost you more in the long run.

Another big lesson? Don’t follow the crowd. If you want to truly stand out in a saturated market, you have to do something different, even if it feels scary or uncertain.

When we started developing TAD’s 3D-printed lashes, it was completely uncharted territory. I partnered with OPT, a U.S.-based microprinting company, to bring this vision to life. It took over a year of development, hundreds of prototypes, and 108 different material variations. But because of my deep understanding of lash products and their commitment to innovation, we formed a true manufacturing partnership, and together, we created something no one else had done before.

Manufacturing has never been just a business strategy for me, it’s been a way to build something meaningful, create jobs, and bring truly innovative products to life.

Contact Info:

- Website: https://tadbeauty.com/

- Instagram: https://www.instagram.com/tadbeautyshop/

- Facebook: https://www.facebook.com/tadbeauty

- Linkedin: https://www.linkedin.com/company/tad-beauty/

- Youtube: https://www.youtube.com/@tadbeautyshop

- Other: https://www.tiktok.com/@tadbeautyshop

Image Credits

Samantha Bearden (wedding photos)