We caught up with the brilliant and insightful Megan Buchta a few weeks ago and have shared our conversation below.

Megan , thanks for joining us, excited to have you contributing your stories and insights. How did you learn to do what you do? Knowing what you know now, what could you have done to speed up your learning process? What skills do you think were most essential? What obstacles stood in the way of learning more?

I began learning my craft at a very young age. As a little girl, I’ve always been interested in art, and all throughout grade school through my college years I took as many art classes as I could. I loved experimenting with different media and still do! In high school I took every ceramics class they offered. We were lucky to have pottery wheels in class. I would try to throw on the wheel every chance I had! I learned how ceramic white or red clay would mold when shaping it with my hands and I’m still learning skills when working with polymer clay to this day.

After my junior year, I had a summer internship working for a hand rolled clay bead jewelry retailer. That summer I conceptualized photography, web, branding, decal applications, packaging, social media events and strategies for promoting 100% American made handcrafted beads. Not only did I get to try my hand at crafting beads I learned a lot about what it’s like to own your own business and retail storefront. It was a busy and fun summer!

It wasn’t until I attended Miami University that my interest in printing was sparked! My senior year, my professor, mentor, and now friend, Erin Beckloff, encouraged me to take a letterpress class. I remember the first time I felt the texture of the paper embossed with a deep impression and I was hooked! I couldn’t get enough of it. We carved linoleum blocks, printed postcards to posters. That summer after graduation and returning home to the Chicagoland area, I attended all things letterpress and gained more knowledge by talking to other printers in my area which sparked the idea to find my own press. Eventually it led to me buying my first printing press from the Netherlands, which I named Ruby.

Towards the end of that same summer, I packed my car with most of my belongings and Ruby and I were off to visit my boyfriend, now husband, in Texas. It was actually only supposed to be a visit but little did I know that I’d be staying. I had applied for jobs down in Texas before leaving and I accepted a position at a smaller company as a Production Manager. I oversaw print schedules, printers, calligraphers, and assembly with many simultaneous projects for weddings and other events. After working there, my husband and I moved to Portland, Oregon. While in Oregon, I worked for a big print company as a Project Manager. Even though I worked on commercial projects that had fast turnarounds and many types of printing methods, you could always find me talking with the operators near the letterpress machines.

Our next adventure brought me back to the Golden Triangle – Beaumont, TX. After moving back to Texas and working for both a small and a big company, I decided I was going to start my own business, Print Doodle Press. This meant I needed to find a bigger and heavier press, Patsy. Patsy, named after a legendary country artist, has spent most of her 112 years in the South. She is a 1910 Chandler & Price Old Style Press. She is the workhorse in the studio for the bigger items I print, such as greeting cards.

All of these experiences have led me to developing my own artwork for others to enjoy. I love what I do and I take great pride in the quality and experience I provide to my customers. I still have plenty to learn and I’m not done!

Awesome – so before we get into the rest of our questions, can you briefly introduce yourself to our readers.

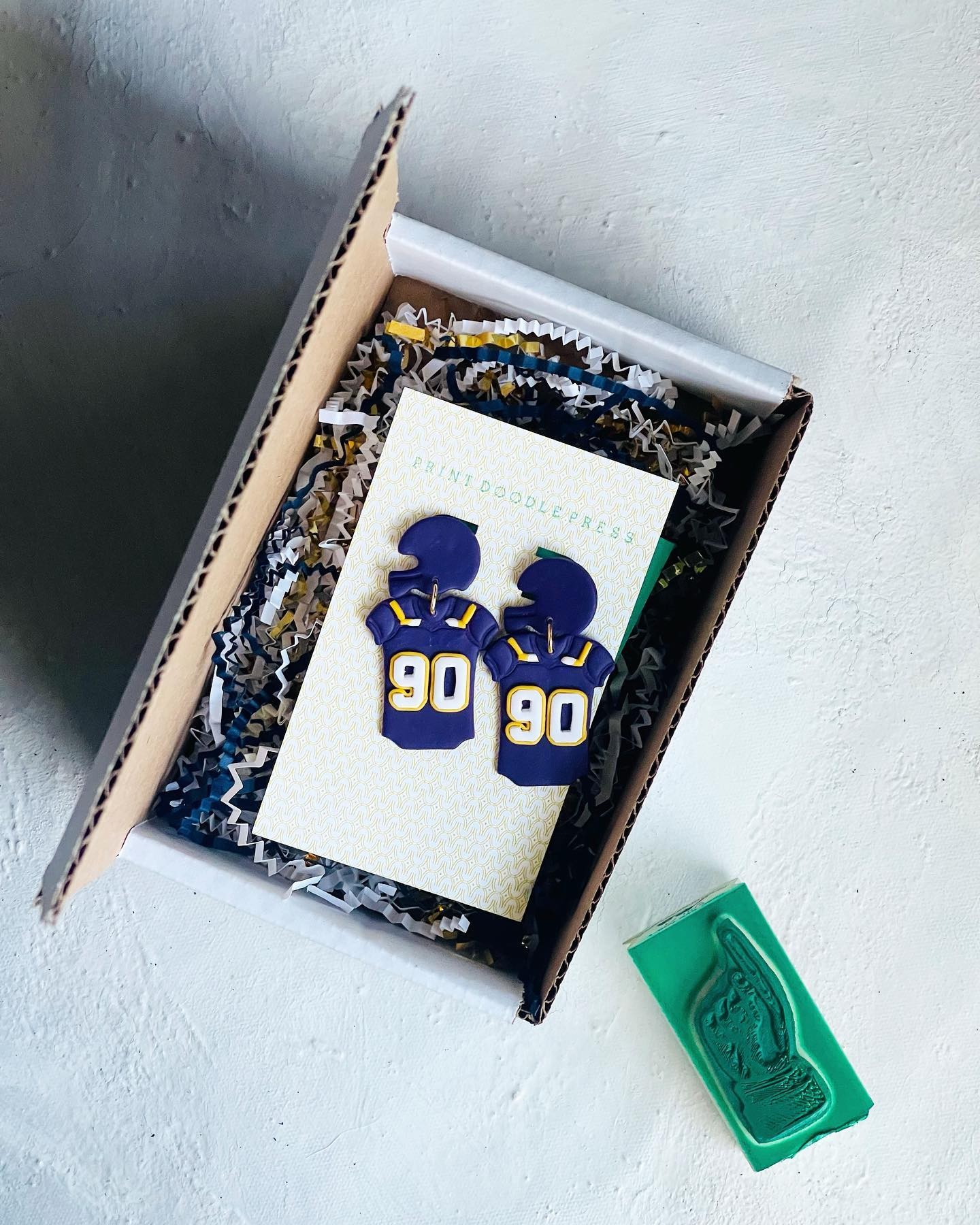

Print Doodle Press (PDP) is a small print and creative studio that specializes in handmade letterpress stationery, design & art, and jewelry. We can create designed logos, help companies rebrand their image, manage projects, and be the ultimate vendor for any print, unique accessories or jewelry-related needs.

Our name is inspired by the initial “doodles” that ultimately evolve and become the finished, polished design our clients fall in love with.

What sets Print Doodle Press apart is pushing boundaries in both the print and polymer clay fields. The amount of detail does not go unnoticed!

Print Doodle Press is home to two vintage presses, “Ruby” and “Patsy” and a large selection of movable type has been accumulated over years of working in the industry. Currently we are hand illustrating several iconic landmarks throughout the Golden Triangle. On the polymer clay side we are constantly using new techniques and styles to create a wide range of jewelry to fit with everyone’s style. All of our “Doodlers” enjoy finding exclusive products only found in our shop!

Let’s talk about resilience next – do you have a story you can share with us?

I think everyone can relate to the challenges that came with 2020 (the covid year). The impact to the wedding industry was significant and the demand for the main service I offered disappeared overnight. I knew I needed to find a way to pivot my business and that’s where my love for clay making and jewelry came back into the picture. I had no idea what was going to happen when I first posted a story sale on my social media, but when the pieces started to sell I knew I was on to something. Since then I have created countless pairs of earrings and it’s crazy to think that this change keeps my small business going. I’ve grown a small experiment at my kitchen table into a significant part of my business.

Has your business ever had a near-death moment? Would you mind sharing the story?

Yes, specifically one comes to mind. The time when the centerpiece to my letterpress operation almost literally fell to pieces… Ever since I made the decision to focus my business on letterpress, I knew I needed to find a full size letterpress to meet my clients needs, but finding a working press is a VERY hard task on its own. So when I found Patsy (only an hour away!!!) I knew I had to act fast! When purchasing a press it’s always a good idea to visit the location first to see what obstacles await.

Oh did I mention, Patsy is 1200 lbs of cast iron so moving her is not an easy task! Being an antique means there are no spare parts readily available at your local hardware store if something were to happen during transit.

At our initial visit it was love at first sight!! I had to have her. The only question now was how to get her out of the house the owners built around her.

The next week, I coordinated a time with the seller, enlisted the help of my husband and his best friend (who are both engineers and all of us former college athletes) to help draft a plan to move the press. My husband decided he was going to make his own pallet to not only fit a pallet jack underneath the press to roll it, but to lift it over a very thick door threshold. Next, we rented a trailer and pallet jack that would carry the weight of Patsy. All three of us then made our way to Patsy’s location.

Once we arrived, we ran into the first challenge getting Patsy out the door once transferred to the pallet. We had plenty of room to get Patsy up and over the threshold however, there was barely enough room to come to a stop on the narrow porch outside the door. All involved pushed her out the door and we saw her lean right on the edge of the porch as she came to a stop. I could see my dream of printing fall to pieces right in front of my very eyes, but with a mighty heave from two of the strongest men I know, we pulled her back from the brink! I knew if she fell to the ground that would have been her tragic end. My sigh of relief could have been heard around the block. Whew!!

There’s more to the story about getting her to the studio, but this was the closest call to tragedy.

Contact Info:

- Website: www.printdoodlepress.com

- Instagram: www.instagram.com/printdoodlepress/

- Facebook: www.facebook.com/printdoodlepress

- Linkedin: www.linkedin.com/in/meganbuchta