We were lucky to catch up with Mark Kuhn recently and have shared our conversation below.

Mark, thanks for joining us, excited to have you contributing your stories and insights. So, naming is such a challenge. How did you come up with the name of your brand?

When we first started, we were working on all kinds of projects and needed a name. I liked the word ‘Foudroyant’ — it is a cognate that means striking as with lightning or stunning; dazzling. I did some word play to rearrange the letters and that’s how we got Oat Foundry.

Now ‘Foudroyant’ is one of our Core Values and we reward to it when people on the team do stuff that is dazzlingly brilliant. One example is Charles, our Sr. Developer creating a tunnel that allowed people from all over the world to play with Split Flaps in our shop. The first group was from Tel Aviv — to see the delight on their faces as they sent messages to each other was so joyous and heart warming. Definitely Foudroyant!

Mark, before we move on to more of these sorts of questions, can you take some time to bring our readers up to speed on you and what you do?

Of all my accomplishments, I am most proud of the way we made it through the worst of the COVID-19 pandemic without laying off any employees. During the pandemic, we were feeling the slowdown from all sides, and my partners and I realized that we needed to make some heavy decisions. We decided not to lay anyone off and instead focus on building products that our community could use and redirect our sales and marketing teams to find people who need them. In the end, we created 30,000 face shields for the Philadelphia region and emerged stronger than we were before.

We started Oat Foundry in 2013 as a team of six Drexel engineers with a mission to build cool stuff. We spent our early days building a range of products from furniture for coffee shops to ice cream packaging machines, to cold brew coffee brewing systems, to THC extraction machines. In 2015, we were presented with the task to build a split-flap display using modern technology while maintaining old-school functionality. It was the first time we were properly using all that engineering training!

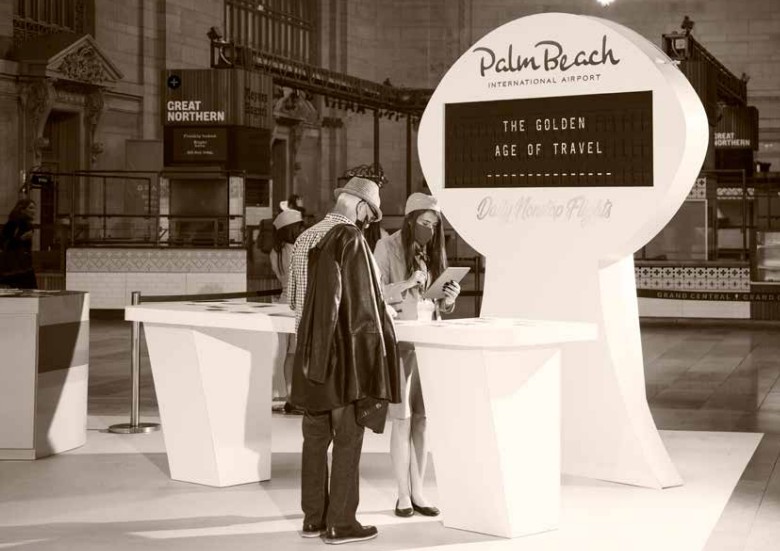

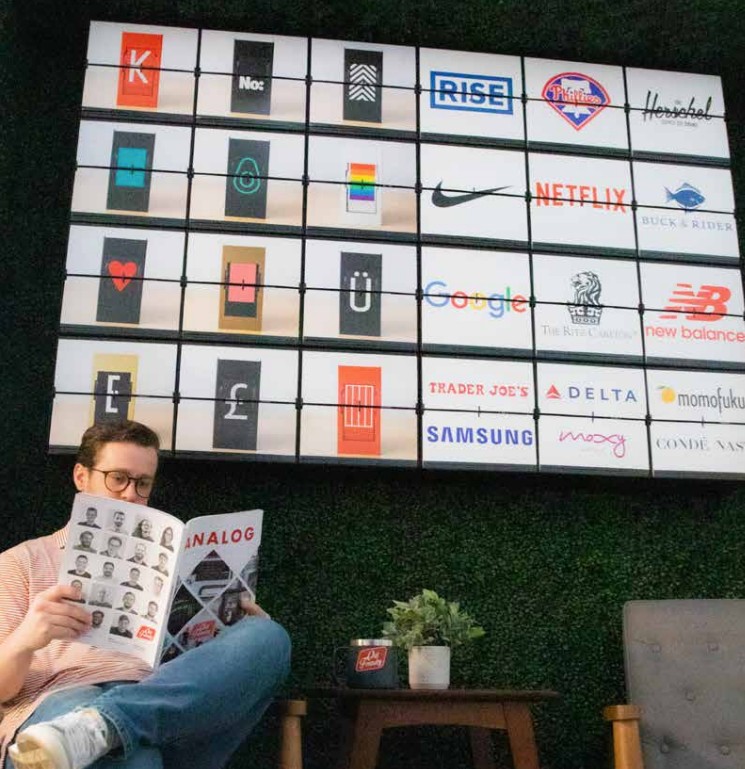

Since Oat Foundry built the first split flap, we have left our original shop in Bensalem, Pennsylvania, and grown into a state-of-the-art production facility headquartered in the heart of Philadelphia manufacturing. We are actually located in an old WWI / WWII bullet and optics manufacturing facility but now solely produce analog technology with our team of 15 employees in four departments. We ship these products all over the world to everyone from Google, to Netflix, to the Institute of Contemporary Art in Chicago, to Hong Kong.

I had the benefit of growing up in the right environment to learn how to make what we categorize as cool stuff. My mother invented the crafts on the craft pages for Highlights magazine and her home office was filled with all kinds of amazing craft supplies. My father had an entrepreneurial spirit – he grew an OB/GYN practice to one of the biggest in the region before selling it. My parents are wonderful parents. They gave my brothers and me a “you can build it” courage. I was an Eagle Scout in my teens and that afforded me even more on-the-fly tinkering opportunities, and leadership training as well. Now I am training to become a pilot. Never stop learning!

Establishing Oat Foundry was an extension of that problem-solving experience. My cofounders and I graduated in June 2013. Ten days later we had an LLC, and within a month we set up our first factory space. Our early plan was to build on a pretzel-machine business we had started in college — that’s another story — but when that project evaporated, we had to pivot.

In the coming years, I project that Oat Foundry will grow to more than 30 employees and become a $15 million product development and commercialization company. We will expand our Philadelphia headquarters while decreasing our carbon footprint and continuing to be a laid-back, fun environment. Our team draws in clever, driven, motivated people that will find camaraderie and opportunities to delight, grow and influence the world.

Okay – so how did you figure out the manufacturing part? Did you have prior experience?

We manufacture both our Split Flap and Picture Flap products here in Philadelphia. Every analog technology journey begins with an idea, some sparked from seeing one of our products in the wild or some beginning with “it’d be cool if we could…”. However our products cross the minds of our clients, we work to achieve their vision of how analog technology should look, feel, and sound.

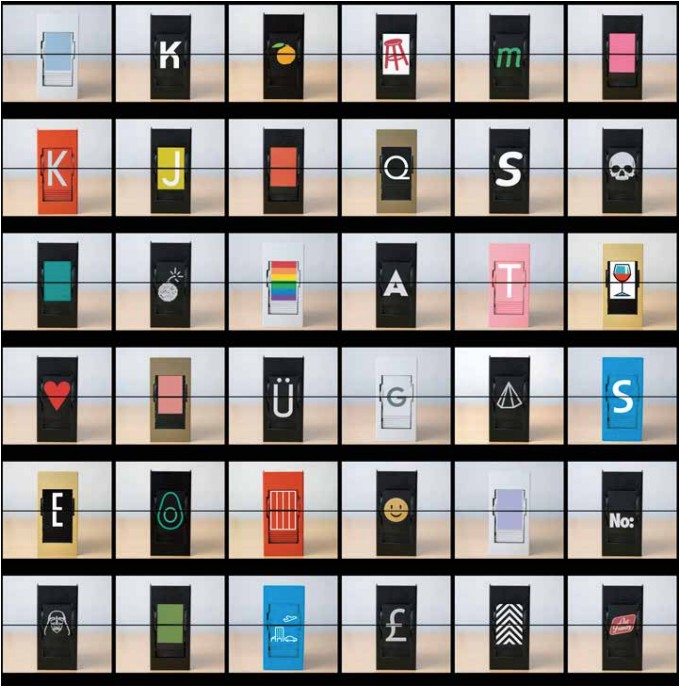

With our Split Flap and Picture Flap product lines, we work with clients from a range of industries: designers, bars, restaurants, dispensaries, and more. The journey begins with determining if the respective client wants a stock or custom display – we provide them with a variety of cost options so they can gauge what best fits their budget and ideas. Our Split Flaps fit in many atmospheres, from a retro strudel bakery in the heart of Budapest or Google’s East Coast headquarters in New York City. Picture Flap is customizable in a different way. The process starts with the client providing us with an array of individual images that form either a complete photo or collage of several different images.

Let’s start at the beginning. Our analog technology in its most basic form is an array of raw materials. These come together to form an interactive, analog display that stimulates the senses through sight and sound.

Oat Foundry has been working with General Metal Company for years. We love that they’re a local business and continuously supply us with the high quality sheet metal we rely on for both Split Flap and Picture Flap signs.

Sheets of carbon steel are rolled to size. A laser cuts out the various shapes used throughout the superstructure of each Split Flap and Picture Flap. The path the laser takes, zig-zagging through the steel, is the result of months of design and iteration work. This ensures that every piece fits into the next, as seamless and as strong as the last. Expert technicians at General Metal Company with years of experience bend these flat laser cut sheets by hand into complex geometries, forming the base part. From there, they check critical dimensions before heading off to the powder coating booth. Here, technicians spray an even coating of electrostatic particles that stick to the grounded bare metal parts. Powder coating allows us to customize the sheet metal, like the white Ritz-Carlton Split Flap and the red Kit Kat display seen later in this book. The parts then pass through a curing oven, where they are heated to change the chemical makeup of the powder, forming a durable long-lasting coating. The parts are then cooled and bagged before their 15 minute journey down the road to our assembly floor.

Screen printing is a meticulous process that we use to create the flaps for

our Split Flap displays. The hard-working team at Nu Art Graphics has been in the screen printing business for over forty years. We trust their expertise, and they’ve printed over 30,000 sheets of Oat Foundry flaps.

The flaps of our Split Flap start with a digital layout, we call it an artboard, which specifies where each artifact will land when shown on a sign. From the finalized artboard, the team at Nu Art Graphics begins the printing process. They start by creating a transparency of the print areas to use in conjunction with UV light to create a negative of the screen. At this point, all black areas allow ink to pass through and all transparent areas do not allow ink to pass through. Once their staff burns the screen, they use it for each set of flaps they will print. Each unique color requires a new screen to be made. Now that we have the tools to print, we need our substrate. Sheets of plastic are milled by hand to an exact thickness and cut to a manageable size. A trained technician aligns the plastic in the screen printing press to precise tolerances. Ink is then flowed onto the plastic substrate, then flipped before repeating the process. These printed sheets are then cured for improved adhesion. A steel rule die presses against the plastic with over a ton of pressure, setting each character on its own flap. Throughout the process, technicians are checking and adjusting for any defects. They wrap the finished flaps and ship them about an hour east to our door. The process is laborious, even considered old school, but it ensures the ink will remain prominent for years to come.

For digital printing, which is used for all of our Picture Flap signs, we work with NGS – a screen and digital printing company out of Elgin, Illinois. They are home to some of the most state of the art equipment in the printing industry. Turning massive, high resolution image files into

physical prints is no easy task and it wouldn’t be possible without the capabilities of NGS. They are home to some of the most state of the art equipment in the printing industry. The Picture Flap printing process begins with our design team laying out the clients’ images on digital artboards prior to sending them out for printing. Each of these artboards start with a template provided by NGS where we can overlay images onto the front and back of each flap. The artboards sent to NGS do not look like pictures, rather a collage of colors that will someday coalesce into a larger mosaic. NGS prints our high resolution image files digitally onto sheets of white plastic – creating our physical flaps for Picture Flap. Large scale digital printing is very similar to how your home printer works. Slowly swiping from side to side, little by little covering the plastic substrate. Once the printer is finished, the raw sheet moves over to the routing station to cut the individual flaps out of a sheet – like an automated xacto knife. The router precisely cuts each flap, some areas being as small as .01” wide. With each sheet printed and cut, a technician stacks each sheet into its respective pile, organizing each flap for each module.

The Split Flap build process begins with sheet metal and flaps in hand, along with a host of other parts. We assemble our custom-designed printed circuit board to the module sheet metal along with a hand-picked stepper motor. At the same time, flaps are being broken out and arranged into the wheels. One by one – these will give the Split Flap that distinctive look and sound as the motor rotates through each character. With module production in full swing, we can begin the build for the outer cabinet which will link each of the individual modules together within the Split Flap. Our trained technicians join a network of sheet metal with rivets and sometimes welded supports. From there we add reinforcements to provide a solid superstructure. Each component is then placed and wired together in the cabinet to finish the Split Flap assembly process.

Picture Flaps are assembled a bit differently. Modules utilize an intricate, finely tuned gear train to achieve the higher torque required to turn flaps that are six times the size of Split Flap. Once this unique, larger gear train has been assembled, it can be joined with another one of our custom-designed printed circuit boards that will drive the motor, and affixed to the module sheet metal. Before mounting modules, a network of backplanes must be wired and fastened to the wall to create the array of rows and columns, creating the aspect ratio of the larger images that will flip through on the Picture Flap. After assembly onto the wall, flaps are populated, the collage slowly but surely taking shape. From there it’s time to test — the display runs through a series of quality checks to ensure functionality, aesthetic consistency, and reliability.

Each component that goes into every one of our products has been individually tested and passed quality checks at various points along the way to becoming a full assembly – at which point we can really fine tune things. With each Split Flap or Picture Flap module in place, we calibrate the motors such that each of the flaps across the full display are perfectly synchronized. This makes animations even better. From there we do final aesthetic quality checks on characters and images as they relate to one another on the board. The displays then run through their final functional acceptance test where each module is put through its paces for thousands of rotations in a simulated use test without experiencing a single error. Now, it’s ready to pack up and start its journey.

Crates are custom made for our analog technology products to get a snug fit for the long ride ahead. We build each crate to suit, just like its contents. It starts with a foundation of thick plywood cross-braced with heat-treated pine planks atop cleats. Walls and a top are fabricated in a similar fashion of plywood with rough lumber bracing. The inside of the crate is then lined with a medium density polyethylene foam to provide some cushion for transit. Our friends over at Arrow Crating and Packaging add some finishing touches before crossing the Betsy Ross Bridge to drop the crate off at our shop.

Our analog tech may move between a myriad of trucks, trailers, planes, and containers on its journey, with dozens of touchpoints in between. Working with our local dispatch, we ensure the crate is safely loaded onto the first truck. From city to city, country to country, we monitor the movement of the crate every step of the way. We work with the on-site team to ensure everything is ready for the arrival of the display. Once it’s navigated loading docks and doorways, it’s ready to uncrate and install.

We take extra care in the handling of every display to get it to its destination safely and on time. Sometimes we work with local installers, guiding them through the install instructions and answering any questions – sometimes our team installs ourselves. From the time we put the first screw into a carousel wheel for it to hold a set of flaps to the last screw we put into the crate before shipping, there have been hundreds of quality checks along the way and thousands of touchpoints by our trained assembly staff and network of suppliers to ensure the display not only functions as designed, but that it does so for years to come. Seeing a new piece of analog tech in the wild, introducing a host of new people in a new location to something different; it never gets old.

There are no shortcuts with manufacturing. To end with beautiful, functional, long lasting products, you need to start with good design, good process, and meticulous quality control.

Have any books or other resources had a big impact on you?

I very much liked Traction EOS — even if a fledgling entrepreneur does not implement every aspect, it was helpful to build some common frameworks and KPI tracking.

Shoe Dog by Phil Knight

Getting Things Done by David Allen

Think Again by Adam Grant

The Life-Changing Magic of Tidying Up by Marie Kondo

Contact Info:

- Website: www.OatFoundry.com

- Instagram: https://www.instagram.com/oatfoundrybuilds/?hl=en

- Facebook: https://www.facebook.com/OatFoundry/

- Linkedin: https://www.linkedin.com/in/markdkuhniv/

- Twitter: https://twitter.com/oatfoundry?lang=en

- Youtube: https://www.youtube.com/c/oatfoundry/videos?app=desktop

Image Credits

I own the rights to all these images