We recently connected with Logan Cannon and have shared our conversation below.

Logan, thanks for taking the time to share your stories with us today Let’s start with the story of your mission. What should we know?

My mission can be summarized in one word—minimalism. It’s undeniable that Americans are overwhelmed by choices in every market from health insurance to condiments to clothing. I’ve found that by limiting my available options, I’m able to simplify my day-to-day, and my mind is more at ease. It’s a bit easier to live in the moment and it’s provided me with sustained happiness. I simply applied this principle to apparel and created a brand that men can trust for style direction and performance needs. However, dressing minimally is more complex than one might initially think (including myself).

Clothing is interesting because it exists for two reasons: performance needs and social norms, and when athleticism is the focal point of the performance needs, the results of crossbreeding it with social norms can be heinous, but it doesn’t have to be. My experience allows me to combine design, fabric technology, and style history to create an elegant collection based on the principles of simplicity, comfort, and performance. I apply my unique perspective of design to provide a solution that is chic, versatile, and long lasting. Currently I’m offering men’s underwear and traditionally-made custom suits. These products are on completely opposite ends of the spectrum but, over time, I’ll fill in the gaps. I’m brimming with ideas and excited to showcase the concept, fully realized.

Athletic and Tailored Articles aim to create clothing that is suited to the modern man’s lifestyle. Our design goal is to create performance quality and versatile athletic clothing that aesthetically blends into the sartorial tradition.

Logan, love having you share your insights with us. Before we ask you more questions, maybe you can take a moment to introduce yourself to our readers who might have missed our earlier conversations?

I don’t have a singularly-disciplined background which is something that’s kept me from getting bored or being pigeon holed. Admittedly, it’s set me back in my career at times, but it’s also given me invaluable experience. I’ve done many aspects of my business at some point for someone else and now get to do it (and more) for myself.

I attended Appalachian State University and studied a combination of graphic design and print/digital technology. I was drawn to it because of my interest in the graphic tee shirt trend. My program covered all forms of print technology, including screen printing, which gave me the resources to experiment with the entire process from ideation to a finished product.

The summer before my senior year, I was required to fulfill one more internship that applied to my degree. By this time, my interests in screen printing had moved beyond graphic tees and onto more technically challenging concepts like the four-color process and alternative substrates to cotton. I approached Carroll Companies Inc, a company just outside of Boone, N.C. that specializes in the production of leather apparel and accessories. They didn’t do any printing but offered to let me see what they did for a week—this turned into a six month internship in pattern making, cutting, and sewing. This in-depth look at how a sewing factory operates helped me discover a professional trajectory that aligned with my creative interests.

I moved to New York a few months after graduating and began working as a graphic designer, learning what I could about the fashion industry along the way. This indirect path took me through freelance and full time jobs at companies like Thom Browne, J. Press, GANT, Brooklyn Tailors, Kate Spade, Clinique, and even HBO. It gave me a wealth of knowledge in branding, marketing, retail, and product design, but I still wanted to further my skills.

I took patternmaking and illustration classes at FIT and Mood Fabrics. I did a lot of sewing in my spare time and explored industry-related opportunities anytime they popped up. There were high points and there were definitely low points. I did this for about 10 years until—driven by my long-time desire to start a company and work for myself—I landed on an idea, and then another idea. So I started two brands: Athletic Articles and Tailored Articles

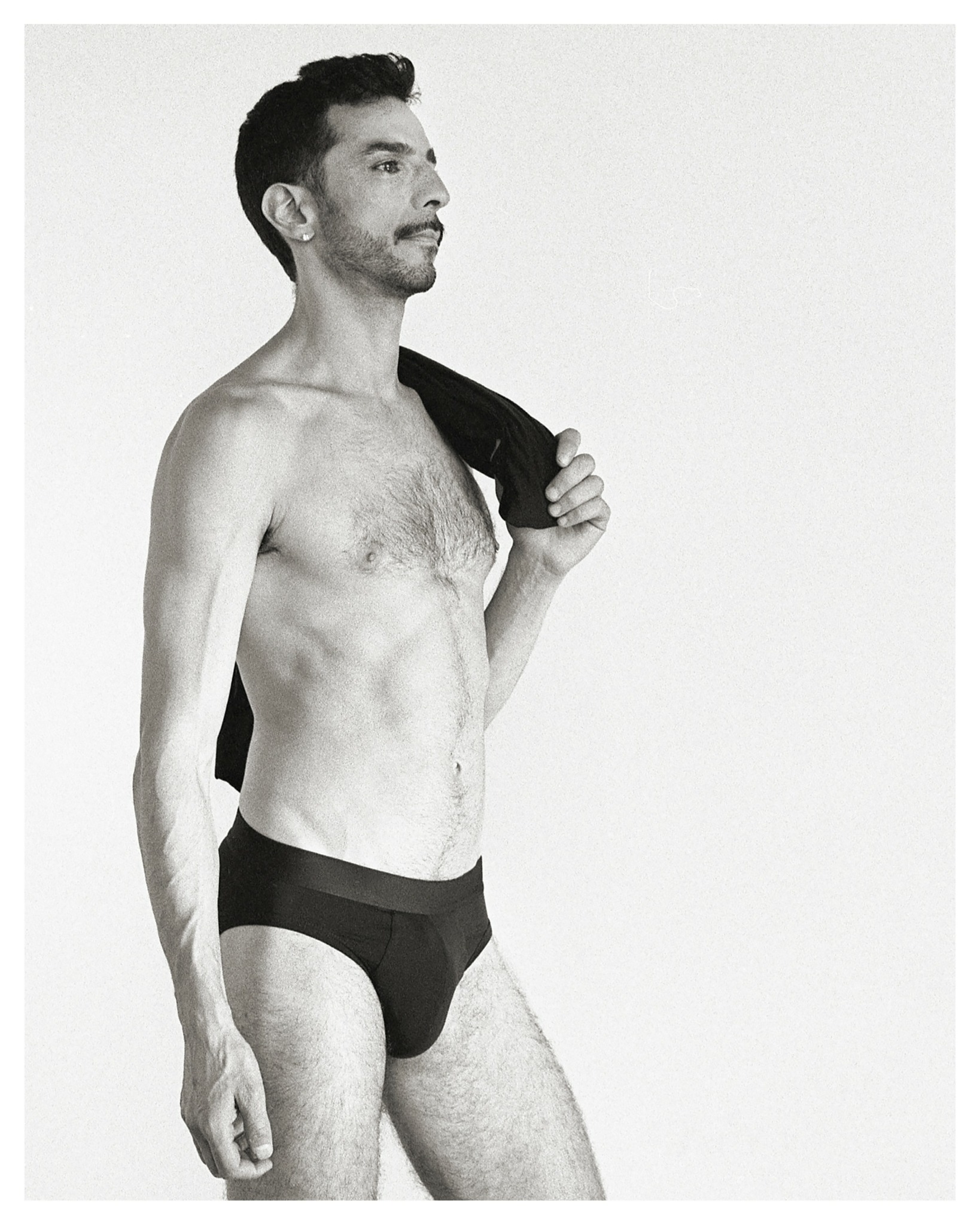

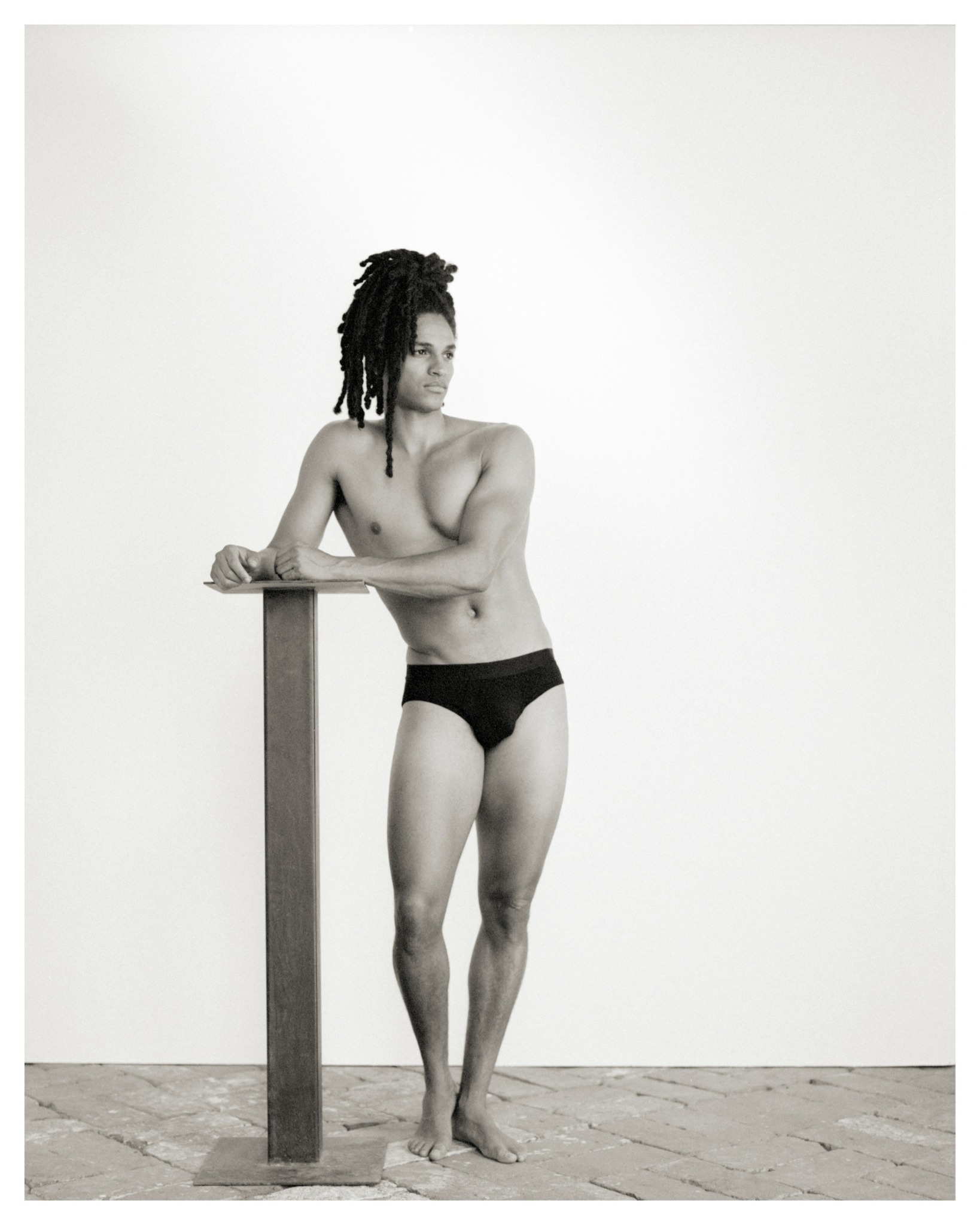

Athletic Articles is focused on athletic apparel. I’ve been a lifelong soccer player, so many of my ideas revolved around performance clothing. I first launched men’s underwear. The line solves the problem of having separate underwear for daily life and for athletic purposes by performing as both. Athletic Articles underwear is made of natural fibers, is incredibly soft, and lightweight for everyday wear. It’s also breathable, and fast drying for any athletic pursuits. Sustainability and subdued style were top of mind so they’re environmentally conscious, forgo branding on the waistband, and omit any kitschy product features.

On the other side of the spectrum is Tailored Articles, my custom suiting brand. I worked as Retail Director for Freemans Sporting Club, a custom tailoring brand that used to be here in New York. I ran store operations as well as the Made to Measure and Made to Order suiting programs. In 2021, they decided to cease operations and I saw this as an opportunity to keep what I had developed at Freemans and make it my own. I purchased the domestic Made to Measure tailored clothing program to create Tailored Articles.

These two brands are my foundation and I’ll fill in from either side of the merchandising lines over time. My goal with these two brands is to offer a combination of quality, sustainability, and versatility. Shopping for new quality clothing will be expensive; there’s no way around that. I want to make clothes that are personal and that last, making the pricepoint worthwhile. Fewer pieces of high-quality clothing are much better for everyone than an abundance of low-quality clothing. I believe this concept can be applied to most things we have and use.

We’d really appreciate if you could talk to us about how you figured out the manufacturing process.

I manufacture all of my products at the moment. Once I had decided to make underwear, I used my knowledge of the industry to start asking the right questions. Over time, I was educated on the supply chain process while my design wheels spun. I made drawings and sourced prototypes that I could use as the foundation. I was referred to a producer in LA who had worked for American Apparel. She took on my project and sampling began in mid 2019. But after three rounds of attempts and a better understanding of US apparel production, I decided the quality I wanted wasn’t going to happen domestically. It’d been nearly 40 years since US apparel companies began outsourcing their production, and in that time the US had fallen behind due to a lack of new development. I wasn’t convinced that I would be able to find the best fabrics or produce the best garment in the United States. This is where the story gets interesting.

In this time I learned of TENCEL – a patented fiber that would be ideal for what I wanted to make. I contacted TENCEL’s owning company and was graciously given an international list of the mills they work with. There was a Portuguese mill on the list that had a rep in New York. I visited him and discovered a collection of fabrics that blew me away. I told the mill I was interested in working with them and they also gave me a reference list of cut and sew factories they worked with in the Portuguese region. Coincidentally I was working for a clothing brand at the time who was also considering outsourcing production to Portugal, and coincidentally I was sent there on a scouting mission. For the record, I did my job on the scouting mission, but I also parlayed the trip into my own mission. This was by far the biggest leap in learning I’d made so far, and within a few weeks of my return, I had received samples and knew who I wanted to work with. That was March 2020. Most people have Covid stories of overcoming difficulty, but for me, Covid gave me a time to think and plan. I still needed to come up with a brand name. Being forced to slow down was probably the best thing that could have happened and I ordered my first production run about 20 months after my visit.

For Tailored Articles, however, the story is far more simple. The same company that had sent me to Portugal had also tasked me with setting up a domestic Made to Measure tailored clothing production program, since its previous one had closed during Covid. Although tailored clothing was certainly affected by apparel outsourcing, the technology is only obsolete for mass production. In fact, the best tailoring in the world is made one piece at a time and sewn entirely by hand. That said, there are only a handful of traditional tailored clothing factories left in the US. Our obvious choice was Rochester Tailored Clothing based in upstate New York. Fast forward another year and Freemans goes under and I had the foresight to acquire the tailored clothing program for next to nothing.

For both of these experiences I learned the importance of communicating a clear idea of what the intended product should look like or function as. Even though the initial idea might not be the final product, it is important that whomever is helping to execute a vision has the same vision as you do.

Do you sell on your site, or do you use a platform like Amazon, Etsy, Cratejoy, etc?

Currently I only sell DTC through Shopify’s e-commerce and POS platforms. I was able to do the design and website build myself, so the barrier to entry was quite low. Shopify’s platform tools and available integrations are incredibly insightful and allow me to run detailed reporting, manage inventory, and many other important operations with one service. I see no cons in investing in and maintaining this channel as it will be an invaluable tool to already have in place once sales really start to scale.

For luxury apparel, though, there is a ceiling of organic traffic when the brand is still young and relatively unknown. I’m currently focusing on reaching as many applicable wholesale accounts as possible to drive bulk sales and build brand awareness through established retailers and department stores.

Contact Info:

- Website: https://athleticarticles.com

- Instagram: @athleticarticles

- Linkedin: https://www.linkedin.com/in/logan-cannon-988391236/

Image Credits

Marvin Castro Studio; Goodness and Truth Studio