We’re excited to introduce you to the always interesting and insightful Kevin Miranda. We hope you’ll enjoy our conversation with Kevin below.

Kevin, looking forward to hearing all of your stories today. What do you think Corporate America gets wrong in your industry? Any stories or anecdotes that illustrate why this matters?

In an age where almost everything you own is made at an unknown location by a nameless, faceless person (or persons), the surfboard industry is one where many members wish to do things differently. For some, it may be about the fame or recognition, and for others, it may be about standing behind your work proudly. Regardless of the reason, in providing the consumer an honest product with a transparent production process (or at least semi-transparent), both the consumer and the creator have much to gain. Despite there still being plenty of variety when choosing things like a new blender or shelving for your room, buying a product like a surfboard requires much more knowledge, understanding, and personalization in order to get a proper fit. With so many variables to factor in, such as wave conditions, surfer’s size, ability, personal equipment preferences, and future surfing goals, pairing the right surfboard to the surfer is closer in alikeness to a samuri needing a custom crafted sword than someone merely going to the store and grabbing curtains or a pot that fits your color scheme. Unfortnately, as what happens with many companies and industries that become focused on increasing output while also creating a greater profit margin, this customization process becomes a thing of the past and both the consumer and creator are left with a few drawbacks. Although there are many people around the world who are doing their best to operate their business in a way that stays true to the craft, there are also many other companies who look at what they make as purely another on-the-rack , “pop-out” product rather than an artisan creation, and in doing so, are greatly changing the landscape of the surfboard industry.

When the customer has no knowledge of who was hands-on during the production process, where the product was made, and at least a basic understanding of how the product was made (understandably leaving out certain details if they’re trade secrets or key developed techniques), they are less aware of everything it took to get their product in their hand, which in turn will result in a decrease in perceived value of the product. The consumer has been left with a heavily saturated market of companies keeping their production behind closed curtains and making their sole aim to sell higher volume while paying less to the people who make them, thus making the possibility of earning a liveable wage as a surfboard builder decrease. There are many ways in which a surfboard builder can add value to the customer when there is greater involvment between them. Certain key converstations that would take place between the consumer and creator that dial in all the fine details to create a personally-tailored surfboard often increase the odds of the consumer spending their hard-earned money on a board that properly caters to their desires. It is when the local board building communities are able to do their thing that the craft stays alive. However, without it, surfboards will simply become another mass produced product made overseas that has lost its “soul”.

Kevin, before we move on to more of these sorts of questions, can you take some time to bring our readers up to speed on you and what you do?

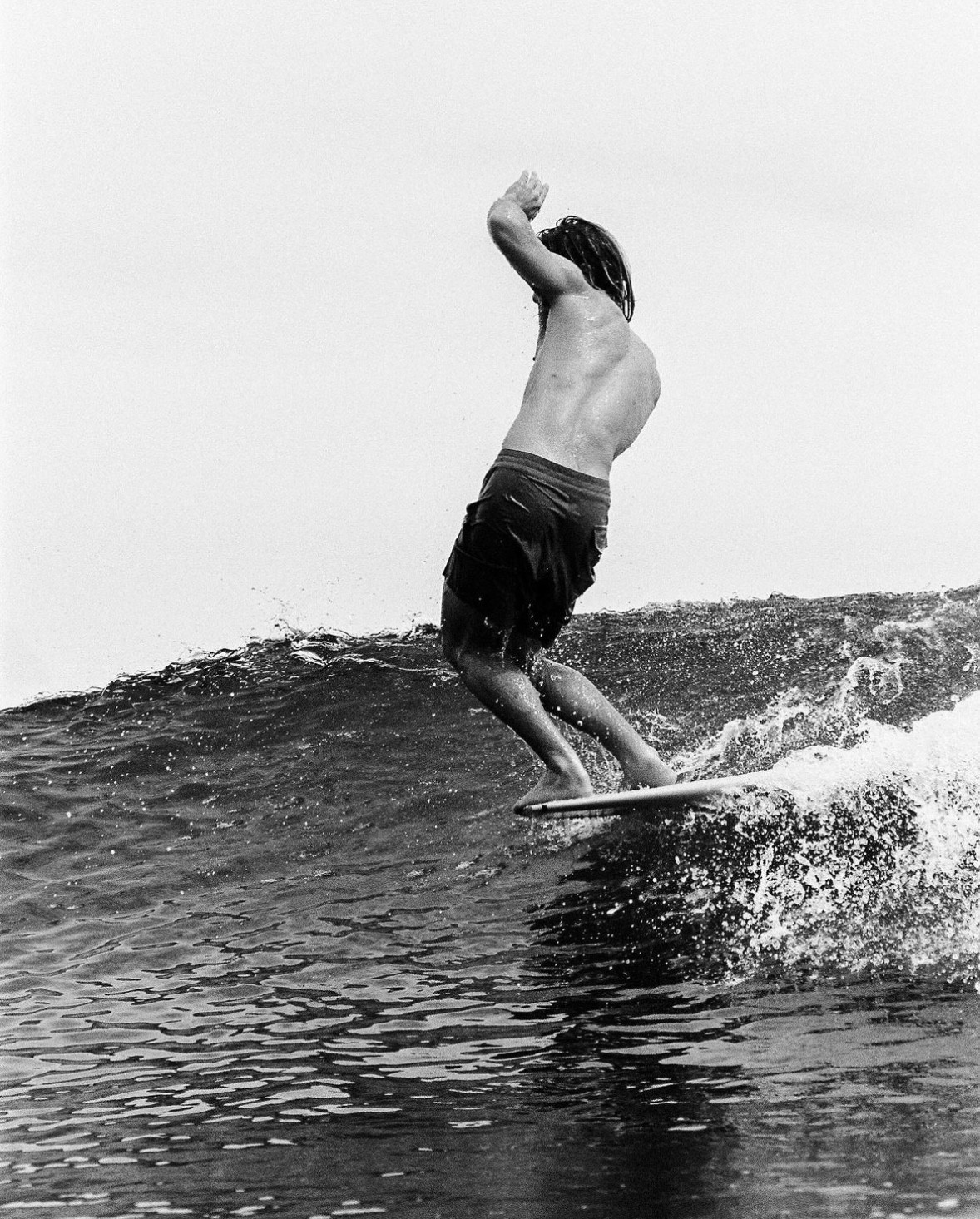

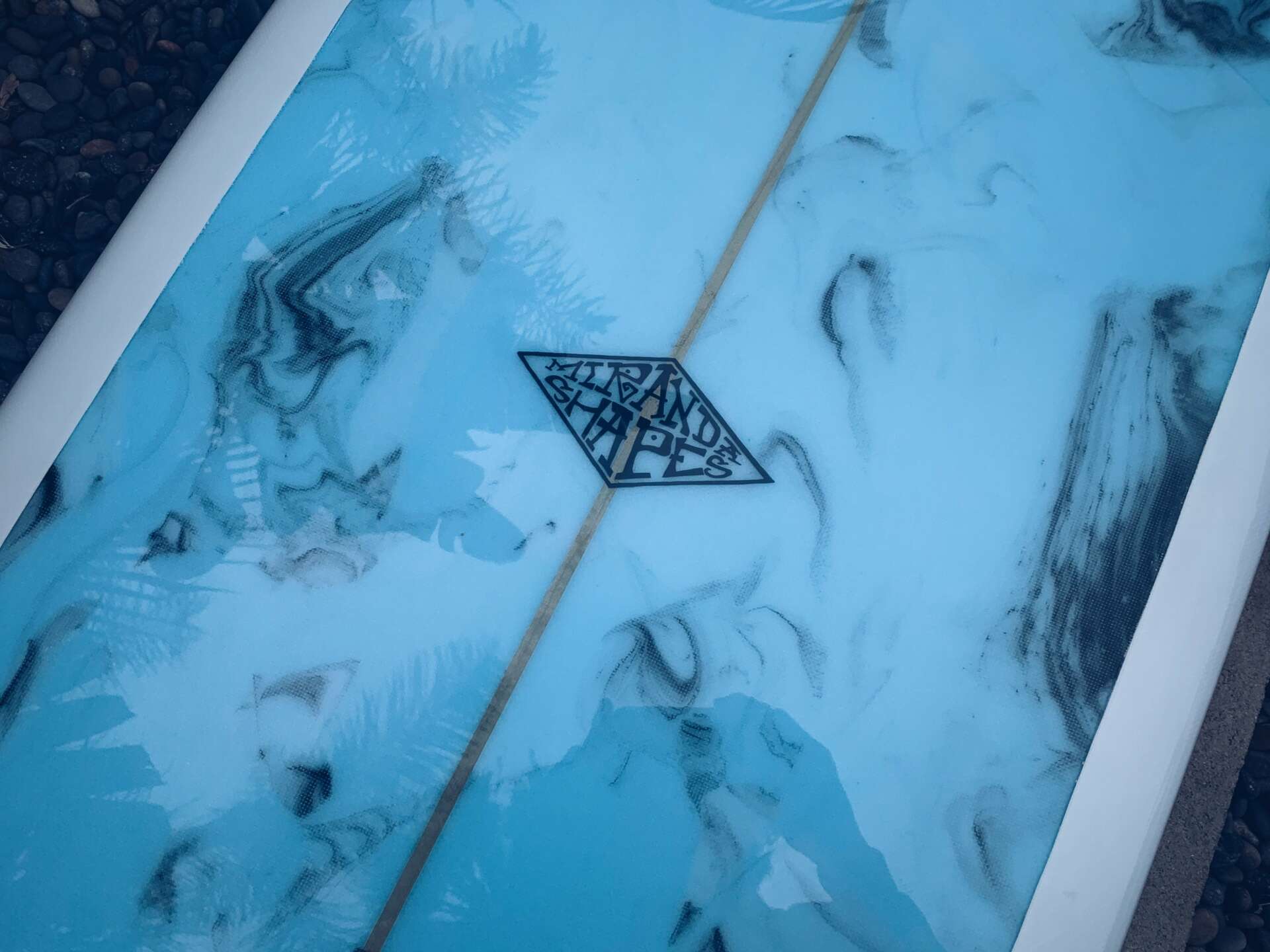

My name is Kevin Miranda, I’m 24 years old, from Long Beach, CA, and I am the owner of Miranda Shapes. I enjoy shaping surfboards of great variety in lengths, styles, designs, colors, etc. for others (and myself of course) to put to use. I entered the industry shortly after graduating high school in hopes of finding a creative outlet that was a bit more practical to the buyer than the previous artwork I was making, which was primarily drawings and paintings on paper and canvas. Given that surfing had become a big passion of mine during high school, the board building industry seemed like a great opportunity to connect two of my favorite activities, surfing and making art. Shortly after picking up shaping and making myself a few boards, I began to get friends of mine asking me to make them a board, which then turned into friends of friends asking, and eventually I had people I hadn’t met yet asking (many of which became new friends shortly after). What started as wanting to make a few boards for myself so I could further explore different feelings on a wave turned into a never-ending puzzle of how to acheive those sensations under foot for other surfers who come to me wanting to experience something specific. For some, it may be wanting to have a board that gets them into plenty of waves easily so they can learn faster, or a board that is insanely fast without trying so that it flies all over the wave, or maybe even a board that surfs “slow” so that you can stay deeper in the wave. Regardless of what they want to feel, my job is to take their surfing goals and pair it with the best possible surfboard I can make (at the time) based on my knowledge of hydrodynamics, board design, and overall surfing body-mechanics.

As I began to get more interested in learning as much as I could about shaping surfboards, I also became increasingly interested in creating an overall aesthetically pleasing surfboard. For some, whether the surfboard is one color or the other makes no difference. However, for others having a surfboard that is equally visually appealing as it is functional is of great importance. Thus, as I learned different techniques for shaping and new design elements, I also began to seek out the same towards making a surfboard that stood out from all the plain white boards out there, Although I must say that I believe the functionality and performance of the board comes first and foremost, designing the colorways, choosing how they’ll be applied, and seeking to create surfboards that look how I want has provided lots of room for creative expression. This process as a whole, from shaping out the form of the surfboard, to the conception of the colors/design, to seeing the finished product placed under the surfers feet and them enjoying it has been one of the most rewarding and fulfilling experiences I’ve had as both an artist and a surfer.

Can you talk to us about manufacturing? How’d you figure it all out? We’d love to hear the story.

The manufacturing process for surfboards is one of many steps, from the shaper, laminator, fin box setter, hot coater, sander, polisher, etc., and each requiring a particular skillset and knowledge about the materials, tools, and techniques. For some, they choose to build the whole surfboard, from step A to Z, and for others, they choose to narrow down their focus to one or a few of the disciplines. Although I enjoy learning about all the steps involved in making a surfboard and seek out to learn as much as I can from the industry professionals around me, I have chosen to start with seeking to master the first step which is the shaping of the raw foam blank into a functional form of my design. My very first surfboard was shaped under the tutilage of Kevin Kunhart at Foam E-Z, a surfboard supply shop in Westminster, CA that sells surfboard materials, various surfboard services, and also happens to offer shape lessons (which I now teach). After that day, I knew I just found a new addiction. I sought out to devote as much of my earnings from my job at the time towards shaping, buying a new blank for myself whenever I could. After about a year and a half of coming back to Foam E-Z to rent out their shaping bayfor the day, I was able to snag a job at the shop, and that’s when things really started to get going. Thanks to working there, I was able to surround myself not only with the materials and tools involved in this industry, but also surround myself with industry experts, many of which have been extremely kind and gracious in lending advice or a helping hand when needed. If it wasn’t for this job, I wouldn’t have learned as much, nor would I have been able to devote as much time towards developing my skills. In doing so, I have been given many opportunties to see various pros and cons when it comes to the manufacturing process, both from personal experience and from listening to those around me.

I think one of the biggest lessons I’ve learned when it comes to manufacturing a product, whether you look at one individual step or the whole process, is that there’s always room for improvement no matter what. The moment you begin to believe your product is perfect is the moment you blindside yourself to all the ways it could be developed or improved. With surfboards (depending on who you ask), there’s always room for improvement, or at least a little tinkering. Over the centuries that suring has been around, surfboard design and manufacturing has come such a far way, none of which would’ve happened if at some point we decided that the board was perfect and needed no change. With such a diverse selection of wave types around the world, different sizes and shapes of surfers, and different surfing goals we wish to achieve, there’s always room to see what lies in all the grey areas that have yet to be explored. Whether it be in the shape of surfboard, the lamination, fins, or materials, the next best feeling for the surfer is out there waiting to be discovered. However, it won’t be found if us producers decide that what we create is perfect. That’s not to say we haven’t found some winning formulas or combinations, but there’s always room to find what might be better. In doing so, not only do you keep learning and developing, but you keep the passion alive for what you do.

Have you ever had to pivot?

As I mentioned earlier, when I first started getting into shaping surfboards, I was working another job. I worked for a company called the Skate Kids which gave skateboard lessons to kids all over southern California. I was very passionate about the job and really did love what I was doing, enough so to be willing to work 6-7 days a week happily, but I felt there was a lack of opportunity to use my creativity in a way I wanted. I spent about a year a half asking my boss every couple of weeks to have a day off so I could go shape a surfboard, whether for myself or for a customer. He was very supportive of me going after a dream of mine since he shared the same entrepeneurial spirit, and he had no problem with me taking a day off here and there. They say if you hang around the barbershop long enough, eventually you’re going to get a hair cut. The same thing happened with me and getting a job at Foam E-Z. I was a frequent returning customer for long enough that when a spot opened up, I was there to take it. Getting the opportunity to work there was huge for me and felt like a major milestone in the right direction. I did my best to work the two jobs together, but the more time I spent working at the shop, the more I realized that was the path I wanted to pursue. Although I still enjoyed working with the kids and opening their worlds up to everything that skateboarding gave to me, I started to wish I had more time and energy to devote towards making my way into the surfboard industry and learning more about the craft of board building. It was then that I realized I could either continue splitting my time and giving a split effort towards the two, or I could choose one and devote myself fully towards it.

Although it was a hard decision since my boss at Skate Kids and I were not just great co-workers but also great friends, he was understanding and supportive of my choice to commit to my passion, even in following years. In making that choice, I was naturally able to spend more time at the shop, surround myself with more industry professionals from whom I could learn, invest more effort into developing the skills of the trade, and ultimately focus in on what was the most interesting artform I ever picked up. Making this pivot was one of the greatest decisions I had made for myself looking back from my current position.

Contact Info:

- Instagram: @mirandashapes

Image Credits

@nikonosg (black and white surfing photo) @the_turquoise_shadow (both photos of me shaping…not the photo with 3-in-1 pictures though)