We recently connected with Kathleen Batalden Smith and have shared our conversation below.

Alright, Kathleen thanks for taking the time to share your stories and insights with us today. Can you talk to us about your team building process? How did you recruit and train your team and knowing what you know now would you have done anything differently?

For the first few years, it was only Justin and I working on and in the business. About two years in, we decided it was time to hire our first woodshop assistant. I’ll never forget interviewing our soon-to-be-new hire. Justin welcomed him into our kitchen and proceeded to eat a bowl of cereal while asking Bryan about his life and work experience. (Bryan was a great fit, by the way!)

We’ve found that when you’re genuine, transparent, and understanding of people’s life experience and their unique personal circumstances, it’s usually fairly simple to attract and hold on to the type of employees best for your business.

Looking back, if we could do anything differently, two things come to mind: Hire earlier (before we felt 100% ready financially), and document standard operating procedures from the get go, even when it was just 1 or 2 people involved in a task. Having as many aspects as possible of your business standardized (whether in a written SOP, a how-to video, or some other resource) makes it so much easier and more efficient to onboard new team members.

Kathleen, love having you share your insights with us. Before we ask you more questions, maybe you can take a moment to introduce yourself to our readers who might have missed our earlier conversations?

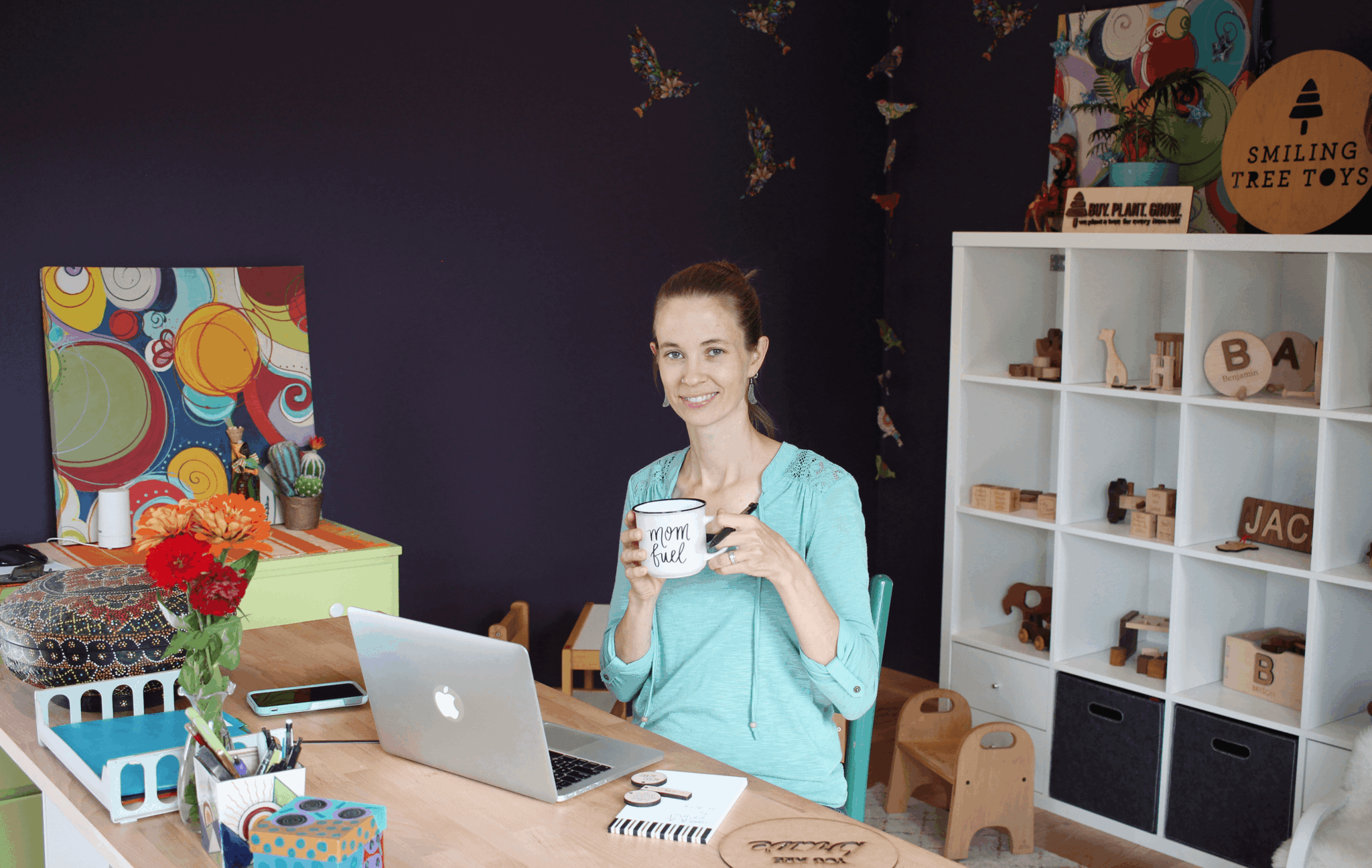

As new parents back in 2010, my husband Justin and I founded Smiling Tree Toys with the vision of helping families make childhood memories through sustainably made, all natural, keepsake wooden toys. But that vision was about so much more than just toys; it was fueled by our personal passions for protecting the planet and doing our small part to ensure it remained healthy and green for the next generation. It was our hope that owning a business hyper-focused on environmental sustainability would give us the means to protect and even improve upon the health of our planet.

The business and our family both grew (a lot!) over the next decade. We moved the woodshop from our unfinished farmhouse basement, to a little white garage alongside our farmhouse, into what is now our beautifully renovated historic red dairy barn turned modern woodshop. As we established a name for ourselves in the high end, keepsake wooden toy space, businesses looking for gifts started to take notice. Soon we were filling larger corporate orders for our toys to be used as employee and client gifts. Many of the requests were for custom engraving on our classic wooden alphabet blocks. No longer were we engraving just the letters of the alphabet and adorable animals to go along with them; now we were turning out blocks upon blocks custom engraved with companies’ logos, brand messages, and other special event graphics.

Fast forward to 2024; we still operate out of our acreage on the Minnesota prairie that we call home, not far farm Kathleen’s family farming roots. We’ve grown our family to four kids, two dogs, one cat, and too many chickens. We’ve scaled our brands – Smiling Tree Gifts and Smiling Tree Toys – to seven figures and now manage a team of ten (some on-site and some remote). Justin oversees production while I focus on scaling and visibility. We have an incredible, tight-knit team of talented, passionate, and reliable people who we’re proud to call part of the Smiling Tree family. We keep our workplace easy going, flexible, and light-hearted. Our promise to our employees is to ensure their work fits into their lives, and not the other way around. The Smiling Tree culture we’ve created and our ongoing commitment to sustainability are two accomplishments we’re incredibly proud of.

It’s a little cliche to say “we’re living the dream,” but for the most part it couldn’t be more true!

We’d really appreciate if you could talk to us about how you figured out the manufacturing process.

We handcraft our entire product line (sustainable wooden toys and corporate gifts) from start-to-finish on our rural acreage in southern Minnesota. Justin made our very first toys and kitchen products one at a time on a scroll saw in the unfinished basement of our farm house using scrap wood collected from local cabinet shops.

Within a year, we’d moved into a single car garage on our property – still cutting one toy at-a-time as the orders came in. During our first holiday season (which coincides with cold Minnesota winters!), Justin would crank up the portable heater in the uninsulated garage and work for a few hours at a time, until his hands got so cold he’d have to come into the house until they warmed up again. Then back out for more.

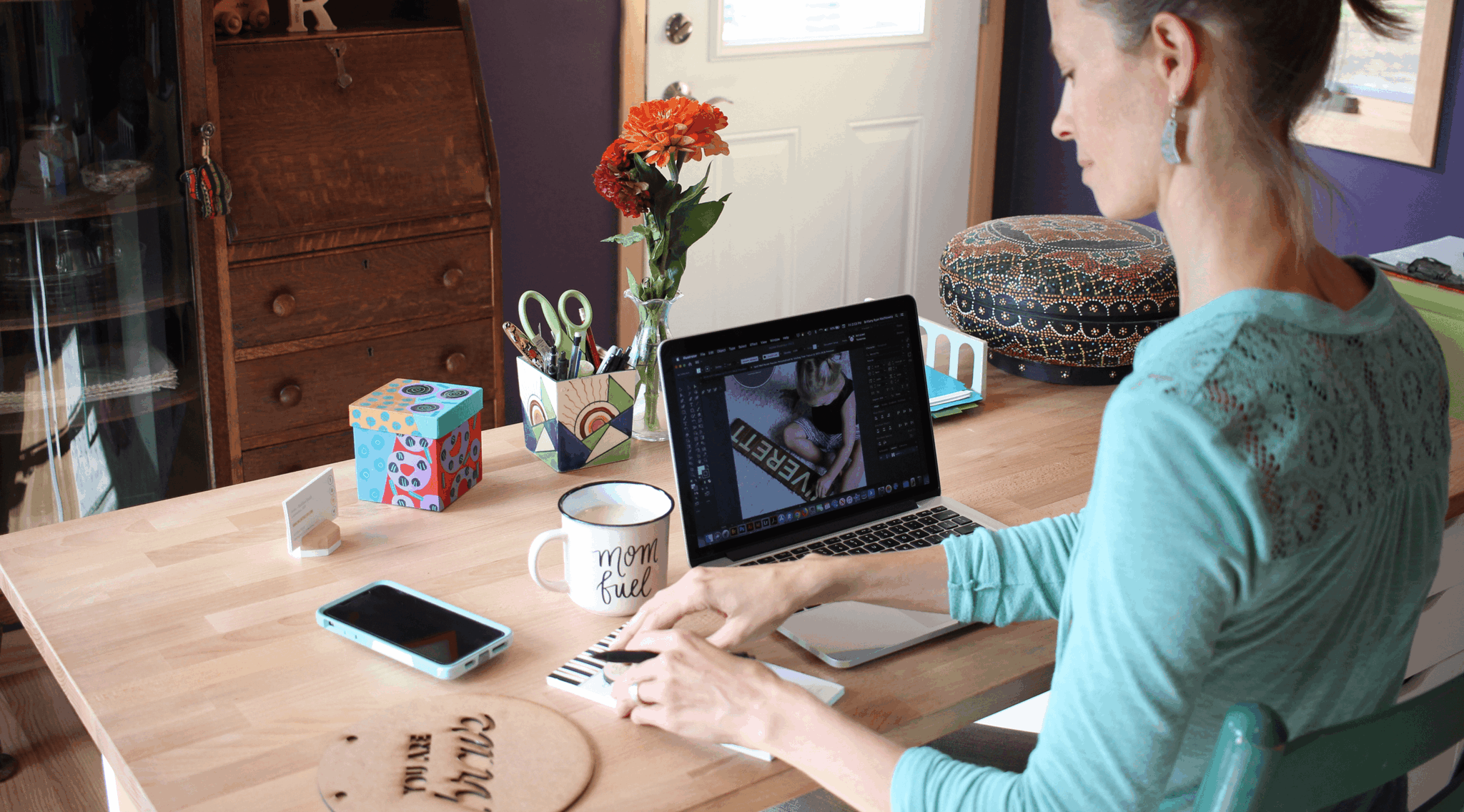

At this point, we were using more wood than we could reclaim from local wood shops, so Justin called around to local and regional lumber companies comparing products and pricing. Meanwhile, I was designing, taking photos, marketing, and shipping orders while also being Mom.

Our original production methods got us through our first few years, but it soon became evident that if we were going to build something that could support our family for years to come, we’d need to take our production to the next level. So we purchased a laser engraver and a CNC machine. They were game changers. The learning curves were high, and we spent countless hours getting to know the machines, experimenting with settings, test engraving and cutting, and ruining more products than we’d like to admit through it all! But it ultimately gave us the ability to produce in larger batches and cut down on our production costs.

Our biggest takeaway? Manufacturing in-house is hard work. It inherently means you need plenty of physical space, overhead expenses will always be affecting your bottom line, quality control never stops, and you’ll have to solve your own production problems.. But given our commitment to sustainability and exceptional quality, outsourcing production was never an option for us. Keeping it all in-house means we maintain control over lead times, quality, costs, and our eco-footprint. And those are things we can’t imagine turning over to anyone else.

Are there any books, videos, essays or other resources that have significantly impacted your management and entrepreneurial thinking and philosophy?

A few books have been especially impactful on my entrepreneurial journey: Fix This Next by Mike Michalowicz, Building a Story Brand by Donald Miller, and Buy Back Your Time by Dan Martell.

Fix This Next helped me standardize, systemize, and rely on systems rather than people to operate and scale our business.

Building a Story Brand completely reframed how I thought about marketing, namely the importance of story telling and framing our brand voice in a way that makes our customers the “heroes” of our story.

Buy Back Your Time gave me the courage to make a key hire that not only let me hand off much of our operations and administrative tasks, but more importantly freed up my time so I could focus on what I do best: bringing visibility to the brand, nurturing our key existing customers, finding new ideal customers, and growing our website traffic.

Contact Info:

- Website: https://smilingtreegifts.com and https://smilingtreetoys.com

- Instagram: https://www.instagram.com/smilingtreegifts, https://www.instagram.com/smilingtreetoys

- Facebook: https://www.facebook.com/smilingtreegifts, https://www.facebook.com/smilingtreetoys

- Linkedin: https://www.linkedin.com/in/kathleen-batalden-smith

- Other: The Friendly Faces Behind Smiling Tree Gifts

https://youtu.be/uxYjRPSS7u0“We Borrow The Earth” – The Story of Smiling Tree Toys

https://youtu.be/vWEoQ5uQHEQ