We recently connected with Jaspar Schirmer and have shared our conversation below.

Jaspar , looking forward to hearing all of your stories today. Getting that first client is always an exciting milestone. Can you talk to us about how you got your first customer who wasn’t a friend, family, or acquaintance?

Starting our first year in business was all about trial and error, which we embraced. My partner, Jaylin, and I brainstormed ways to reach people beyond our immediate network, researching options like flyers, paid media, organic impressions, and directly contacting everyone we knew. We surveyed nearby areas to understand their needs and identified a significant gap: many competitors lacked a strong online presence. This is common in metal fabrication, as most businesses in the industry were established over 20 years ago.

Social media became our top priority, starting with Nextdoor. Jaylin managed our online presence, sharing my work from when I was a welder for a landscaping company. Our posts received incredible support from neighbors. Being able to connect with people in our own community helped us quickly reach our target market. After our second post, we landed a dream project: a 14-foot trailer restoration for our first client, Dominick.

Dominick was the ideal client—patient, punctual, and receptive to additional repair suggestions. This project not only introduced me to my steel distributor, Steel Mart in Tucker, GA, but also helped me identify my strengths and areas for growth.

As a small fabrication shop, we aren’t as niche as larger, more established businesses, so we took on clients of all sizes. This approach allowed us to explore which services were in demand and which smaller, unique jobs we enjoyed taking on. Over time, we began to refine our specialties and carve out a niche in the market.

Having a great first client like Dominick, acquired through organic media, was a clear sign that our services were in demand. It also showed us that growth didn’t require spending hundreds on ads. The support from our neighbors and their trust in our work has been a strong foundation for Jstarr Fabrication to build on.

Awesome – so before we get into the rest of our questions, can you briefly introduce yourself to our readers.

My story began when I was 13 years old. A family friend, Chris Dawson, owned a cart fabrication shop in East Atlanta, where I was first introduced to the world of steel and welding. It took me a few years to get comfortable with the heavy machinery, but after working long hours after school and on weekends, I made significant progress. Chris was more than a mentor—he taught me not only the craftsmanship of fabrication but also the business side of the trade. If my work didn’t meet his high standards, he made me redo it until I got it right.

I carried this determination into my home life, setting up a small garage shop to create artistic pieces for school projects and friends. For my 8th-grade project, I welded a 7-foot steel dinosaur as my final presentation. As the years passed, welding took a backseat while I focused on school, but it was always on my mind.

My final high school project reignited my passion for metalwork. I designed and created three handmade metal sculptures inspired by Alexander Calder, an American sculptor. That project reminded me of why I loved welding—bringing my visions to life and crafting pieces that were both functional and artistic.

When people ask me, “Why welding?” I tell them it’s because I feel most creative and authentic when I’m building. The moment I strike an arc, all my problems dissolve—it’s just me and the weld. Welding is both calming and exhilarating. Steel, with its unmatched durability and flexibility, is the perfect medium for turning ideas into reality.

After high school, I worked with landscape architect Luke Love, who nurtured my passion and gave me my first residential jobs, including custom handrails, gates, and fences. I earned recognition and credibility in my community for my craftsmanship and attention to detail. At just 20 years old, people were often surprised to see me onsite welding and installing my own work. Their reactions motivated me to push myself even further.

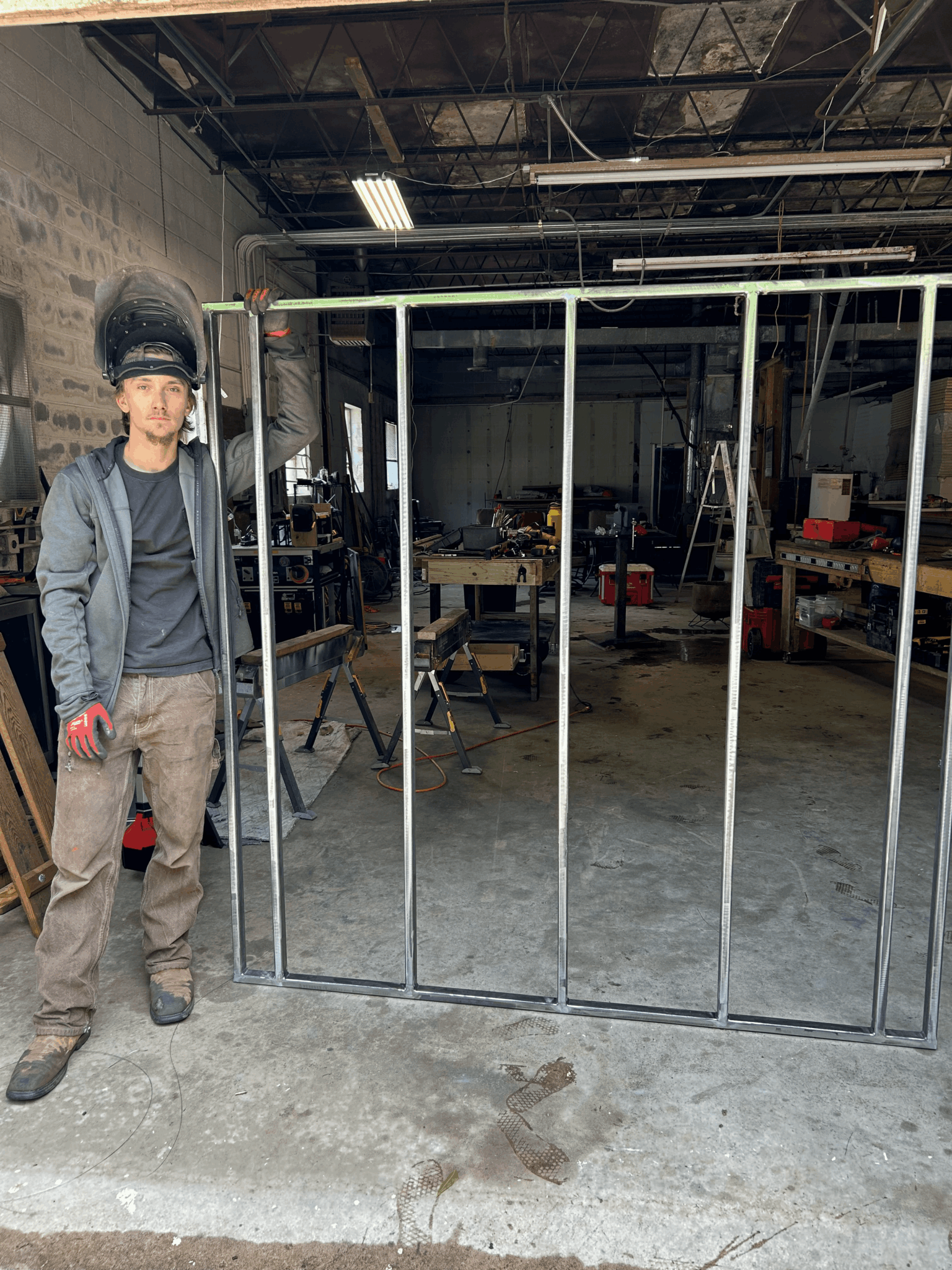

In 2023, I opened my own shop with the help of my friend and partner, Liv Vignos. My shop is like a second home to me, and it has elevated my abilities to take on larger and more complex projects, from 70-foot fences to 14-foot trailer restorations, boat trailers, and custom handrails. Our specialty is trailer restorations and functional exterior projects.

Establishing our brand has been a journey. We pride ourselves on excellent craftsmanship and a strong online presence. Sharing behind-the-scenes glimpses of our projects on social media has built trust and a sense of community. Every project teaches me something new, and I carry those lessons into the next job.

What truly drives me is seeing the excitement on my customers’ faces when a project turns out exactly as envisioned. It’s a reminder of how far I’ve come since I first picked up a welding torch at 13—and how much farther I can go.

We may be a small shop for now, but the quality of my work speaks volumes. If there’s one thing I hope people take away, it’s my passion for what I do and my gratitude for everyone who has supported me along the way.

We’d love to hear the story of how you built up your social media audience?

Social media is one of the best free tools available for small businesses to grow their audience. Whether through paid or organic strategies, it allows you to connect with the right customers quickly and effectively. For our small fabrication business, reaching local clients within a 15-mile radius has been crucial since we specialize in commercial and residential exterior projects. Getting our name out there has always been a top priority, and finding the right platforms was our first step.

We focused on three key platforms: Nextdoor, TikTok, and Meta (Instagram and Facebook). Each plays a unique role in our strategy. Nextdoor helps us connect with potential clients nearby, fostering trust and credibility within our local community. TikTok, on the other hand, allows us to reach a broader audience quickly, thanks to its rapid organic growth potential. Meanwhile, Instagram and Facebook serve as portfolio platforms, showcasing our completed projects while building lasting relationships with quality customers.

Our approach is all about tailoring content to each platform’s audience. On TikTok, we get creative, sharing behind-the-scenes clips and fun, engaging content. On Nextdoor, we focus on project updates and fostering local connections. Instagram and Facebook strike a balance between creative storytelling and polished professionalism, highlighting project showcases, updates, and announcements.

For those just starting to build their social media presence, my advice is simple: start small and stay consistent. Focus on one or two platforms that align with your target audience, and post regularly to stay visible. Showcase a variety of content, from tutorials to behind-the-scenes glimpses, and always engage with your followers by responding to comments and messages. Lastly, experiment with your content to see what resonates best, and adjust your strategy accordingly.

Social media is a long-term investment, but the connections you build can have a lasting impact on your business. For us, it has been an essential tool in growing our audience, strengthening our brand, and connecting with clients who value the craftsmanship and dedication we bring to every project.

We’d love to hear a story of resilience from your journey.

Problems are no stranger to us, especially when starting out. This year alone, we’ve faced challenges like finding the right accountant and securing reliable transportation for materials. One of the biggest lessons I’ve learned came this summer during a major steel pickup.

I hadn’t yet installed a proper rack on my truck to handle heavy loads, and I ended up transporting 800 pounds of 24-foot steel rods. It was one of our largest pickups, and while the trip from our steel supplier was only ten minutes, it felt much longer. My truck was at maximum load capacity, with the rods hanging over the back and swaying back and forth as I drove. It was a nerve-wracking experience, but thankfully, we made it back to the shop safely and unloaded without an issue.

That close call taught me the importance of preparation and safety. Afterward, I designed and installed a cage-like rack for the truck to protect its top and efficiently handle heavy loads. It was a valuable lesson in adapting and problem-solving—essential skills when running a small business.

Contact Info:

- Website: https://jstarrwelds.com/aboutus

- Instagram: jstarrfabrication

- Facebook: Jstarrfabrication

- Linkedin: https://www.linkedin.com/company/jstarr-fabrication/?viewAsMember=true

- Youtube: https://www.youtube.com/@JstarrFabrication

- Yelp: https://www.yelp.com/biz/jstarr-fabrication-avondale-estates

Image Credits

Jaylin Osborne