Alright – so today we’ve got the honor of introducing you to Jarret Schlaff. We think you’ll enjoy our conversation, we’ve shared it below.

Jarret, looking forward to hearing all of your stories today. How did you come up with the idea for your business?

We didn’t start Pingree Detroit with a product in mind, instead we created our cooperative to address two problems; The need for purpose driven work, especially accessible to US veterans in our community who want to work with their hands, and the severe lack of sustainable alternatives to the wasteful, toxic, carbon heavy footwear and fashion industries who put profit ahead of the well being of their workers and the planet.

I landed on footwear in 2015 when I was still researching what we could do to create work and resiliency for veterans. An elder in my neighborhood in the Islandview neighborhood in Detroit actually said, “Sounds like you’re going to be the Boots on the Ground in Detroit”. I had considered footwear, but this was the inspiration I needed, and at that moment I threw my figurative hat over the fence and got to work on bringing forth the first shoes manufactured in Detroit since the 50’s.

Awesome – so before we get into the rest of our questions, can you briefly introduce yourself to our readers.

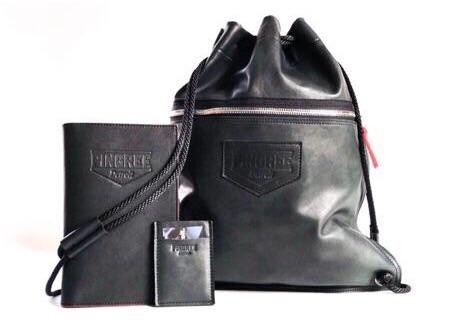

We like to say our Pingree Detroit products smell like a new car because they nearly were.

The leather used by the Detroit Auto industry is some of the most durable, beautiful, and soft material on the planet. When you sit in a car for the first time, and touch that leather steering wheel, you have an instant appreciation for the craftsmanship of that car and the worker who made it. We saw an opportunity here in Detroit to take the leather that was unused or “scrap” from the production of new cars and put it in the hands of our skilled veteran makers instead of it getting shipped overseas or landfilled. The result is something that is uniquely Detroit and gives this leather new life. We are on a pathway as a company to becoming zero waste, toxic free, and carbon negative in all our processes by 2025. We aim to eventually grow and manufacture many of the textiles and components we use in our production process as well as source the majority of our materials from the Great Lakes Watershed.

Can you talk to us about manufacturing? How’d you figure it all out? We’d love to hear the story.

I’ll start by saying you don’t have to have experience in the field you want to get into – just start with what you’re good at, or what you’re passionate about, and work at it every day. I had zero manufacturing experience, but I really cared about helping people, was passionate about creating stronger neighborhoods and not leaving anyone behind, and I found other people who shared my values and were willing to mentor me and join our team to bring this Idea to life. We started with duct tape patterns of shoes, I slowly found a shoe designer named Steve Schock who then helped us grow our team, we eventually found people with hard skills who were willing to teach others, industry experts to mentor our team, and then found larger partners to donate old sewing machines, a place to share space with us ( AnewLife Prostetics) where we could afford a very low rent while we launched production, and then 3 private investors and the Gingras Maker Fund who believed in us and our vision enough to put $150k collectively into getting us off the ground. It took 2.5 years of development and failing at hundreds of small things, and learning from those failures, putting payroll on my personal credit card, to eventually launch footwear and accessories, now with over 28 product skus and a team of 14 people 8.5 years later. My mantra is, “Make a way, anything is possible.”

How’d you build such a strong reputation within your market?

We stand behind our products for life, and seek to have nothing we make ever go to landfill, so word of mouth increases incrementally every year. I also personally oversee all customer service, and will until I can afford to hire an operations person who can hold that space. But being attentive and open to hearing customer needs, being honest about limitations, ( Few realize how complicated it is to design, fabricate, test, and launch something that people will actually want and buy – we have a 7 page design process document, and we get a request nearly every week of someone who wants to pay us Amazon prices for a 1 of 1 custom thing they want because we don’t currently offer it. )- It’s amazing and inspiring that people want to give us their business, but everyone is not our customer and we can’t make everyone happy. So have a bunch of pre-saved ” templates” to respond to the same questions you’ll get regularly, that are on your FAQ that no one reads, ha, and just genuinely come from a place of gratitude and know you are only where you are because of the relationships you have and the quality of goods/services you offer.

Contact Info:

- Website: www.PingreeDetroit.com

- Instagram: https://www.instagram.com/pingreedetroit/

- Facebook: https://www.facebook.com/PingreeDetroit/

- Linkedin: https://www.linkedin.com/company/pingree-detroit

- Youtube: https://www.youtube.com/channel/UC9ttRjdvbY4LQaybk1o0S4g

- Other: Tik Tok: https://www.tiktok.com/@pingreedetroit

Image Credits

@PingreeDetroit