We recently connected with Gnitter and have shared our conversation below.

Gnitter, thanks for taking the time to share your stories with us today Getting that first client is always an exciting milestone. Can you talk to us about how you got your first customer who wasn’t a friend, family, or acquaintance?

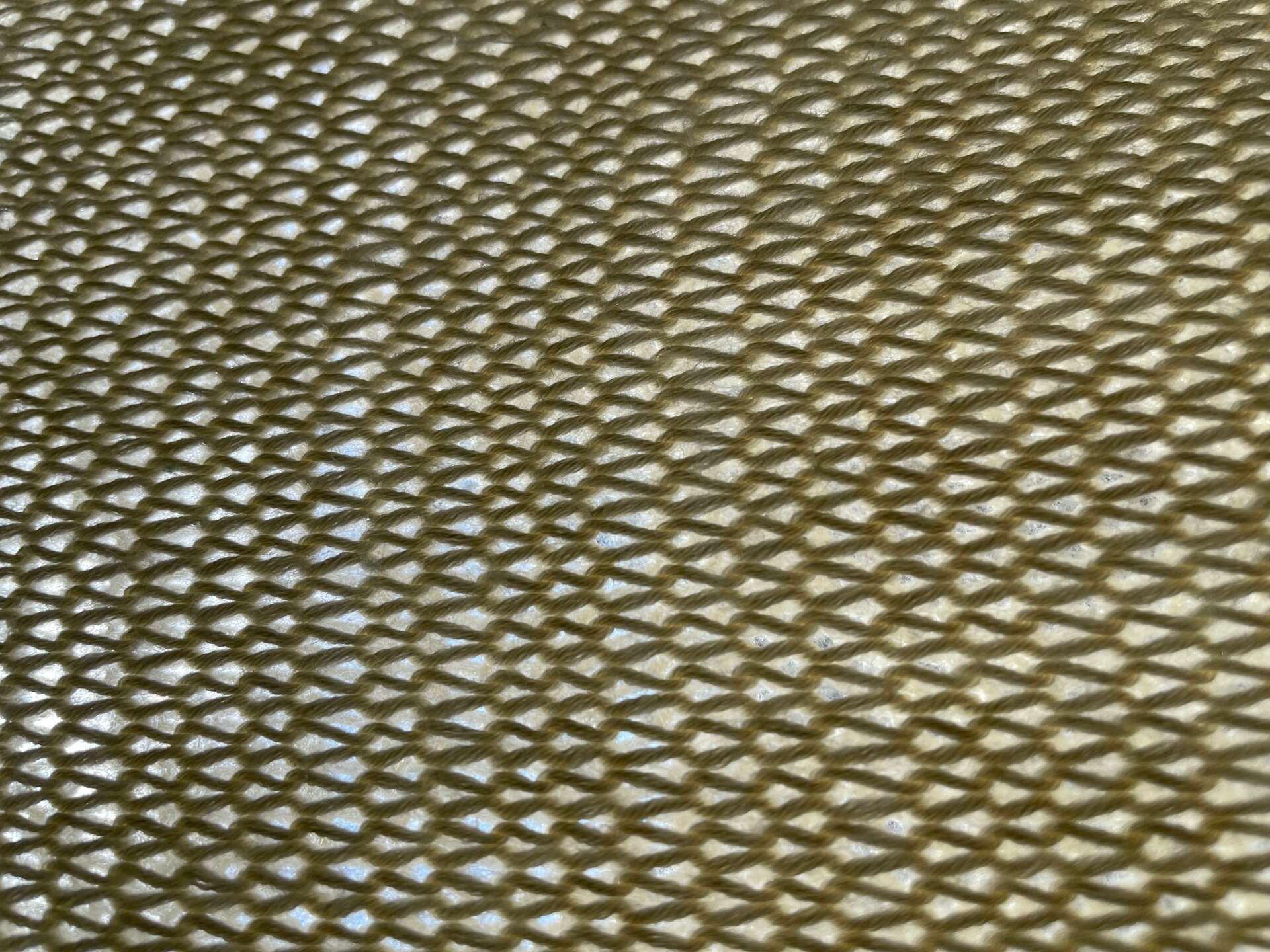

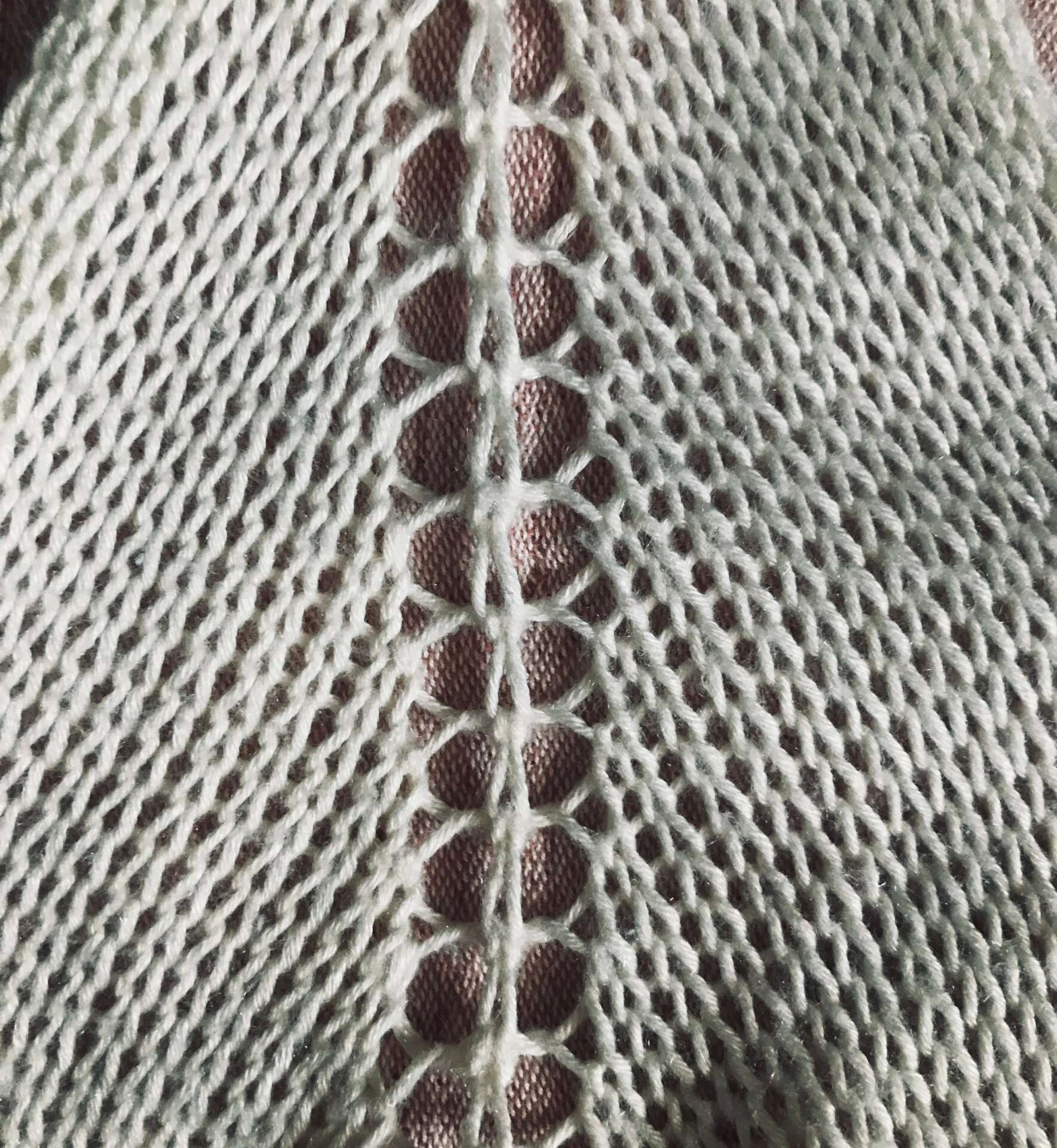

My first customer actually came at random. I posted a “the process” photograph to my social media story of a garment I was making for myself; he [Trillion] responded to it requesting a men’s, long-sleeved, fitted shirt. The specification between a crochet and a knit stitch was made, and he was able to choose the variation he wanted for his woven fabric based upon the photo he responded to. He chose crochet, which was a delight to me, because at the time I was more familiar with gauging crochet pieces for exact + snug measurements. The piece curated for him was actually featured in the last interview Voyage conducted with me. It was free for all as far as the design I came up with, however, I was influenced by his vibe and wanted to create something that I felt would fit him and his style of dress. I finished his shirt within about 2 weeks — an original pattern — and I charged $90 because at the time I did not have a pricing scale created for myself. The particular design ,inspired by him, has actually been requested for consumption by other men, however, I make subtle variations such as seam-work, fiber, length, etc. so it’ll be clear that my first customer gets to move around in the one-of-one prototype.

Gnitter, love having you share your insights with us. Before we ask you more questions, maybe you can take a moment to introduce yourself to our readers who might have missed our earlier conversations?

So, my craft was physically introduced to me at the age of 9, courtesy of my paternal grandmother. One summer day I walked into her room to find her yarn stash sprawled across her bed. I was intrigued by my finding, and my clear interest was apparent to her leading to her teaching me the mechanics of crocheting. I never planned on basing my livelihood on the art, it came into fruition in my early adult/late teen years. I initially made garments and small pieces to give away to family, however, I noticed that strangers were interested in my work as well as the time went, so Gnitter was birthed. It’s a very small, one woman operation that consists of me either reproducing pieces — upon request — that were experimental prototypes, as well as creating original designs based upon what I feel will suit my client best.

When we had our last conversation, I was working with myself, independent of a job. I was able to support myself for about 6 months until business slowed down and I began working for the man.The biggest challenge for me thus far has been time management and production. My current work environment doesn’t allow much, if any, time for personal use, which was stated to me, in so many words, about a month ago. Previous to this, I would work on projects in my down time. This leaves me with the evening time to work on anything I want to complete; it took me great discipline to actually allot time to complete certain tasks, especially since I prefer to do everything at my own leisure. I hate fixed schedules.

Nonetheless, I still weave garments for sale. I’m still a Gnitter. Continuing to keep motion on that end, whilst dealing with a job and iffy rest (except for the weekends) gives me a bit of a driving force. Gnitter, built to last.

Any advice for growing your clientele? What’s been most effective for you?

Word of mouth. Initially I would think about how I could continue to expand and connect with new potentials, since I didn’t have a “marketing strategy,” however, people seeing my garments on other [as well as people seeing my in the motion of making something] grew my clientele. My clientele grows my clientele.

We’d really appreciate if you could talk to us about how you figured out the manufacturing process.

I manufacture all of my products. Slow, manual manufacturing is a skill set I take pride in, I feel like the process is more intimate that way. I have ventured into producing items with a non-electronic loom I bought from Walmart, however it’s still a very hands on process. Math, I’ve come to find, is the most important aspect of my production. Whether it be proper measuring techniques, gauges, stitch count, etc. the numbers always prove their importance. There’s nothing like a beautiful piece with a horrible drape all because I didn’t treat the numbers like they were important.

Contact Info:

- Instagram: @gnitter

- Business Email: [email protected]