Alright – so today we’ve got the honor of introducing you to Donna Dearinger. We think you’ll enjoy our conversation, we’ve shared it below.

Donna, appreciate you joining us today. Let’s start with the story of your mission. What should we know?

My life took a turn when I volunteered for the Red Cross after hurricane Katrina in New Orleans. After 25 years in high tech manufacturing, I needed to use my business skills for something that mattered to people. Weeks after Katrina my husband Russ got his back tattooed. He woke up to find the bed sheets stuck to his tattoo! As an inventor he began researching ideas for a product to protect new tattoos. He incorporate a new business, applied for patents and trademarks and found a manufacturer in the medical supply business. When my job went to China he asked me if I wanted to run the company and I did.

Our first product was Tatu-derm® – a breathable transparent thin film that forms a waterproof barrier on the dry skin around the new tattoo – protecting the open skin from infection and abrasion while containing the body fluid avoiding cross contamination. This was a game changer for the tattoo industry and we still produce our brand in Texas.

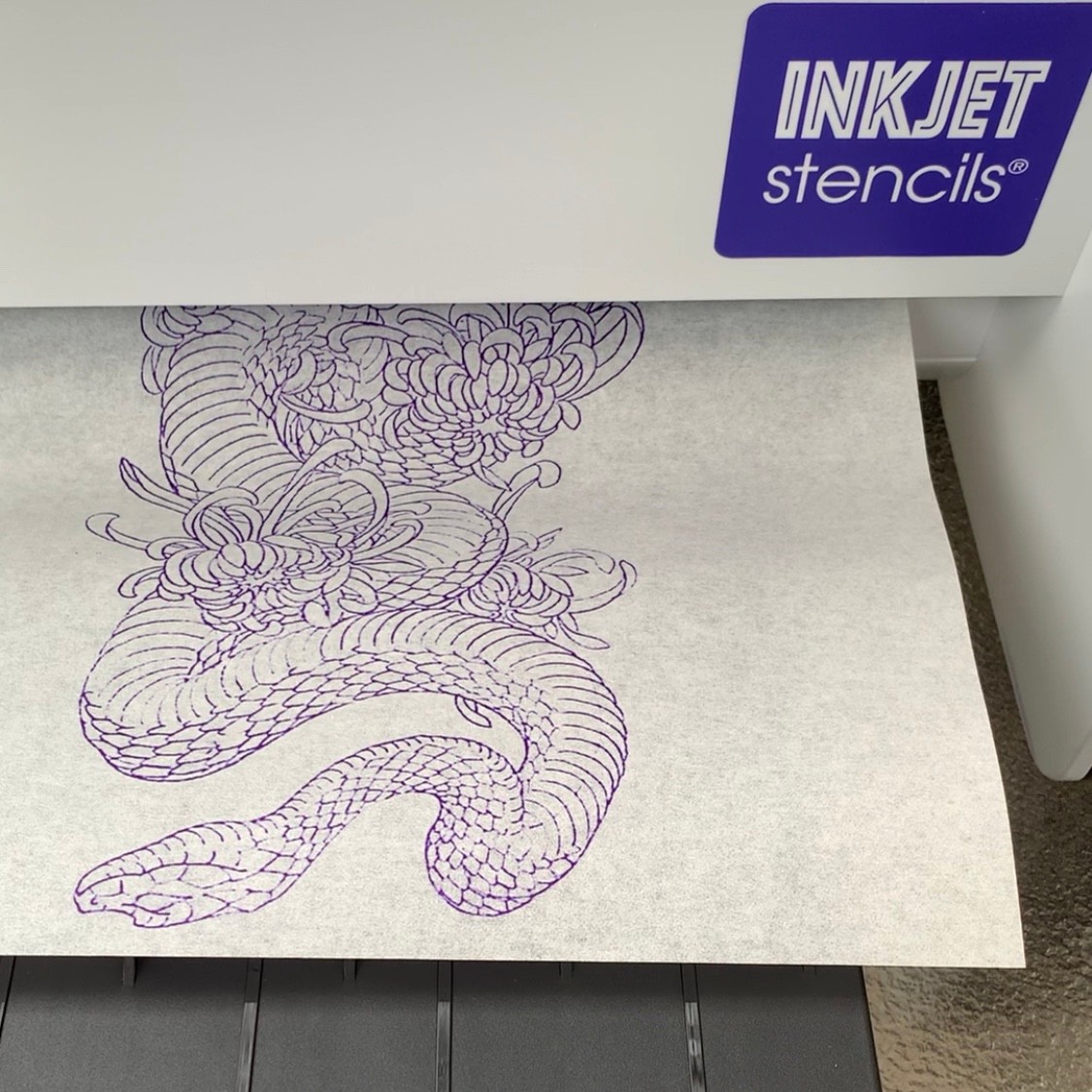

Tattoo conventions were the best way to get our products in front of our tattoo artist customers. Russ closely observed the tattoo process and looked to see where he could improve the status quo. We saw tattoo artists draw their designs on an iPad and place the iPad on a copier, then make a tattoo stencil using carbon paper. Tattoo arts were improving exponentially but the stencils used printing technology originally patented in 1923. Russ went to work filing a patent on printing tattoo stencils with 21st century inkjet printing technology and I went to work looking for a printer manufacturer to make printers for us. At the time we thought we needed our ink in a cartridge but no printer companies would partner with us knowing the application would be on human skin – it didn’t fit their business model. After 8 years in our development, Epson launched the first tank printers. We found a local industrial ink manufacturer to make our ink and began field tests with 6 tattoo artist customers. Our ink in a new Epson EcoTank printer created a photographic quality hi resolution tattoo stencils for 30% of the cost of traditional carbon paper stencils. We launched InkJet Stencils® in January 2018 and had customers on all continents (except Antarctica) in just 10 weeks!

The plan was to offer a better quality stencil for the same price or lower than traditional stencils. Paper was an integral piece of the system. One artist tested 12 different papers during field testing and found the lowest priced paper worked the best – simple off the shelf tracing paper worked really well. It needed to feed through the printer easily and allow the ink on the stencil to transfer to the skin. I wasn’t planning on being in the paper business and advised customers where they could buy the paper, at a local store. One artist said – “If I can’t buy the paper from you than I won’t buy your ink!” So I called the paper company and they made a custom product for us – regular tracing paper cut 8.5X11″ to fit the printer – in reams of 500 sheets. We are now selling nearly 30 million sheets of paper a year.

The InkJet Stencils® business took off quickly with great customer feedback at tattoo conventions. One day at a show in Chicago a couple of young artists came by to talk to us. They were very excited about how InkJet Stencils® was changing how they tattoo. We were not aware of how many hours artist spend hand drawing traditional stencils. These guys said they save 1 to 5 hours a day eliminating hand drawing stencils. Printing directly from their iPad to the printer is so simple and quick! They were crying and one said “We can go home and have dinner with our families and put our kids to bed!” – instead of staying late drawing a stencil for the next day’s tattoo. This was a huge game changer – changing the lives of tattoo artists world wide.

Business is still growing with our products selling at over 100 tattoo supply distributors worldwide. We sell mostly wholesale. Everything is made in the USA. We have one employee managing operations. We have a 3PL managing our inventory and shipping orders. We are using our business skills for something that matters.

Donna, love having you share your insights with us. Before we ask you more questions, maybe you can take a moment to introduce yourself to our readers who might have missed our earlier conversations?

My husband Russ and I both had 25 years of manufacturing experience when we started our business. Russ was an inventor at 3M and I was in sales and supply chain in the circuit board industry. He could develop a great single product and I could ramp it to high volume. He had many products patented and I had great selling skills. Russ was not satisfied with the status quo and was always looking at ways to improve a product or process. I was always driven by sales growth and new the manufacturing process needed to be efficient to have a high quality product and reliable supply chain. I answer the phone. My phone number is everywhere and when customers call I answer. That means a lot.

We care about our customers, our environment and our employee.

We have just 4 products that all sell to the same customer base.

We are committed to manufacturing in the USA – with our experience we understand our manufacturing partners and collaborate well for optimal results. This helped a lot during the pandemic – we had no delays when container shipping was constrained.

Russ had several tattoos when we got started in the business and eventually I have collected many myself.

What sets us apart from others is we are the innovators, so many others sell cheap copy products. We only sell what we manufacture.

Can you talk to us about how your funded your business?

We have always been self funded. We started with just $30,000 cash, selling direct to consumers with many small retail orders. The margin was good but the volume was low. We invested our retirement fund resources for cash flow for the first ten years.

Although we had great credit scores and lots of home equity no bank would give us a business line of credit – until we didn’t need one. Bankers would love our story and business model but would never go beyond that.

Most businesses give up when they aren’t profitable right away. We persisted knowing we offered great innovations to the industry and it has paid off.

We paid more in taxes in 2023 than our total revenue in 2017. Now we have a business line of credit with our bank but we don’t need it. We are debt free and are generous donors.

Have you ever had to pivot?

After visiting some of our largest customers I saw how many employees they had and the expense of office and warehouse space, I made the decision to focus on wholesale. This strategy paid off.

Early on our average order was less than $50. Now our average order is $6,000

The wholesale strategy keeps expenses very low – one employee, no brick and mortar.

Last year we started drop shipping direct from our manufacturers to our distributors. We offer free shipping to the customer which is a huge incentive for them to buy in bulk. We save the cost of shipping to our warehouse, receiving the products, storage fees, picking, packing outgoing shipments… Now we ship an average of 70% of our revenue direct from the manufacturer to the distributor.

It’s a win win.

Contact Info:

- Instagram: @inkjetstencils

- Youtube: www.youtube.com/watch?v=VFukgfhwcEk

- Other: phone 408-891-8181