We caught up with the brilliant and insightful DeAndrae Douglas a few weeks ago and have shared our conversation below.

Alright, DeAndrae thanks for taking the time to share your stories and insights with us today. Naming anything – including a business – is so hard. Right? What’s the story behind how you came up with the name of your brand?

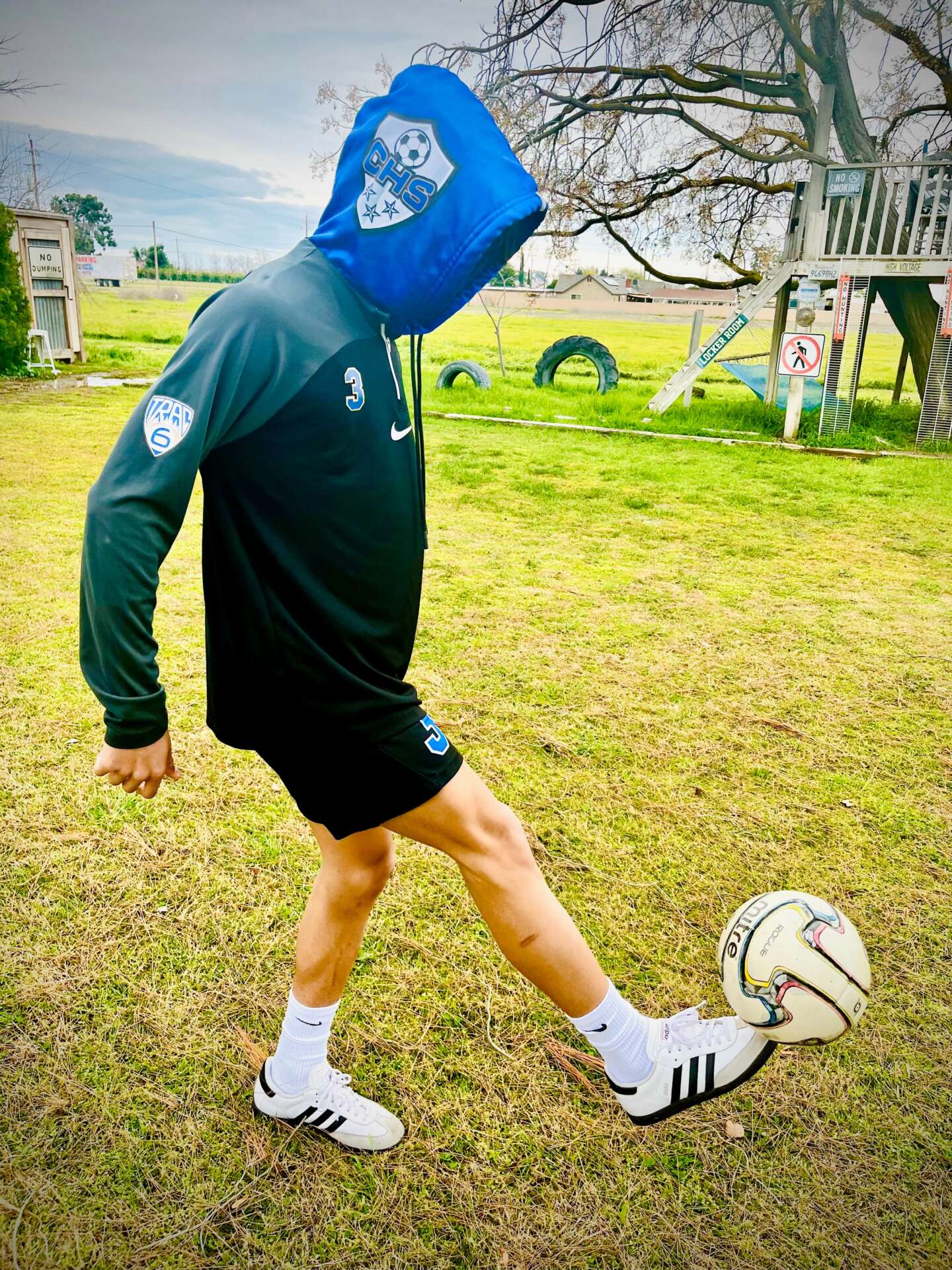

As you know, I make a very unique product. So unique that I was able to get it patented. When I came up with the idea I had to go with something that stood out but closely represented what I believed my product did and I didn’t want to come up with just a general name. I said to myself, since my hoodies transform regular outfits into hoodies, there is something magical about that. I started thinking about famous magicians and came up with Hoodeenys, named after Harry Houdini, and my slogan read “Like magic, we turn outfits into hoodies”. I also created a logo of a rabbit coming out of a hat wearing my hoodie. To my misfortune though, I was soon informed by my patent attorney that I couldn’t use that name because another major clothing company made a jacket that was called a Houdini jacket that was trademarked. This took place months after I had already gone into production so I then had to cut all the labels off my apparel and go back to the drawing board. I resolved that it needed to be something even more descriptive of my product but still simple and then “Boom” it hit me.. Andahoodie! Why Andahoodie? Because it literally describes what it does. Wear any outfit And-A-Hoodie. And it flows so smooth off the tongue. I started imagining strangers saying it. I pictured myself walking around and hearing random people saying the name. It made sense to me and I stuck with it.

DeAndrae, before we move on to more of these sorts of questions, can you take some time to bring our readers up to speed on you and what you do?

First I would like you to know that I have never been much into fashion. I would throw clothes on growing up that didn’t match, I would accidentally bleach my colored socks and wear them to school anyways. I only cared about playing soccer. With that being said, I came up with Andahoodie back around 2012 when my now 15 year old son was still in preschool. It was a rainy day and I needed to pick him up from school so I grabbed a this waterproof jacket I had just bought but it didn’t have a hood on it. I then decided ai would wear a hoodie underneath it but the bulk of the hoodie prevented me from being able to fit my arms in the sleeve of the jacket. It was at this point that I started to reflect on a piece of safety equipment we use at my job as a full time firefighter that we call a “flash hood” which helps protect our neck and ears when we go into fires. We wear these under our turnout coat so I thought if I can wear that and it cover my head, why can’t I do the same with a regular hoodie with a similar design ..and then “boom”, Andahoodie was born. I then started realizing that there were hoodies everywhere, hoodies at school, hoodies at church, hoodies on the movie screen, hoodies all over social media, hoodies being worn even in the summertime. Literally everywhere I looked I saw hoodies. They call this the Baader-Meinhof effect, but not only did I just notice people wearing just hoodies, I started noticing how many people were wearing them under their shirts and under their jackets. Seeing this only served to confirm that I invented something that was not only innovative, but practical. The next step in this process was to bring my idea to life in the form of an actual pattern, so I found a fashion designer to take my vision and put it on paper. A pattern is each piece and component of your product put on a piece of paper that can be used to make more of your hoodies. Basically sewing instructions, and just so you know, a custom made pattern was absolutely necessary to this product as opposed to a t-shirt or jeans because is new and has not been done before. After the pattern was made, I had to protect my idea so as you already know, I started to work extra 24 hour shifts and saved up all my money to get it patented. Once it was patented by my attorney I started the search for the fabric I wanted to use for this product. Once I sourced the fabric I had to find someone to cut it all. Most cutters require a marker “a large piece of paper that lays out your pattern in a way that the cutters know how to cut it for the most yield. After the fabric is cut, you need to find a finisher/someone to sew the pieces together using the sewing instructions you had made by the fashion designer. After the product are sewn you need to package them and now the hard part begins of marketing your product. It’s easy to market a product that people are used to wearing already like t-shirts and jeans but not so easy to market products no one has seen before. Nonetheless that’s where determination and grit come in because when the world doesn’t see you, it’s easy to get frustrated and down but you can’t quit on your product because you then quit on yourself. The amount of trials we have faced on this journey so far is enough to make you wanna walk away but when you understand that you can’t find success without trials then you look at them as a right of passage. There’s land mines everywhere but they won’t kill you and you have to look at trials that way. You may lose an arm or a leg but in this industry if you don’t give up, it will grow back. It only kills you when you quit trying to make it. I’m on a mission though and I have my goals and dreams that I want to achieve before I’m ready to settle down. I will say though, my goals are something that can always be met before I set larger goals. At first my goal was to sell one hoodie to a stranger. Something about selling it to someone I have never met validates the idea that something I came up with is valuable enough for someone else to spend their money on it. Now that this has been completed I moved on to bigger goals like selling them to teams and whole schools. I’m currently at this stage but my dream and my vision for Andahoodie is to walk into a stadium one day and look around and see my hoodies on all the fans cheering for their favorite team.

I personally touch every Andahoodie that’s made. I want perfection so if I don’t think it looks right then I correct the problem, even if it’s just a loose string. To me, loose strings screams cheap and I don’t make a cheaply made product. I want to be known as a company that makes a good apparel. Part of how I do that is to keep my manufacturing here in the United States. Yes it costs more but I also have more control over how I want it to look in terms of quality. I send the pieces out to get sewn, they come back to me done, and I inspect them and bag them. Is it stressful? Yes but you gotta do this in the beginning when you build it from the ground up. Someday I know I will look back and say “Dang, I remember when I set up shop out of the spare bedroom in my small house”

Have you ever had to pivot?

My first time introducing Andahoodie to an audience was right before covid hit. We were in Reno and I had a booth set up at a convention. When people saw the hoodie they were amazed. I generated so much interest and people were ready to buy them for their schools as part of their spirit wear collection but what happened next was somewhat unpredictable on my end because that week Covid made land fall to the U.S. and had started to take off. By the time we got home from the convention, within a week they were calling for all the schools to shut down. All the momentum I built at my first convention was taken away. It was truly bad luck. I wanted to keep making these hoodie because other companies were showing interest. I contacted my fabric cutter to see if he could cut me some pieces. He told me he couldn’t because under the govorner everyone in the apparel manufacturing industry was only allowed to make medical related supplies that our country was short on to help fight Covid. In my opinion I thought it was awesome to see the whole industry pivot for the good of man kind but it left me in a position where I had to make decision. Do I sit on my butt and do nothing or do I pivot myself. I pivoted, and started making masks. Although it wasn’t my main product, it was a product that people needed at the time and I was happy to be able to supply them with it. It worked out well but it wasn’t my bread and butter and as Covid stopped impacting us as much as it was, I began to pivot back to hoodies full time. Till this day there are Andahoodie masks still floating around though.

We’d really appreciate if you could talk to us about how you figured out the manufacturing process.

The process I went through to building my product was a long and difficult process. It could have been easier but I didn’t know anything about the fashion industry before I got started. There are companies out there though that will do everything for you but I chose a different path for cost control reasons. When I first invented my product, I had a dream to take it to the next level but I didn’t know how, and as fate would have it, I ran into someone who could help me with the first step.

I was at dinner with my mother and our server used to be a good friend of my sister back in elementary school. He used to live in LA as a fashion designer but was back in Fresno because things didn’t go as planned for him. I told him about my invention and that I didn’t know what I should do next and that’s when he asked if I had a pattern made. I said no. He said that’s the first thing I needed. I asked him if he could help me with this and he said yes and came over a couple days later and drew me up an official pattern.

The next step was to find the fabric I wanted to use so I took a trip down to LA to find some with a buddy of mine. We searched all day long and by late afternoon we found some of the sweatshirt fleece we were looking for. We then bought it and proceeded to walk around downtown with these huge rolls of fabric on our shoulders looking for someone to cut it. We used google to find one, walked up to their door and cold call knocked on it. They opened it and looked at us strangely. I said “ we’re here from out of town and are looking for someone who could cut our fabric”. The two people looked at each other and then asked if we had a marker. A marker is a giant piece of paper the width of your roll of fabric that has all the pieces to your product drawn on it and tightly spaced so the cutters can cut as many pieces as you can get out of that roll of fabric. At the time I didn’t even know what a marker was so I said “No but I have a pattern”. They looked at each other again and said “Ok, we can use that”. Then we asked, “Do you also happen to know any sewers?” They said they did and would send the pieces and the pattern to them after they were done cutting. 2 weeks later I had my first batch of Andahoodies. We have since established a relationship with a fabric supplier and have it delivered straight to the cutter who then cuts them and sends them to me. I take the fabric and apply the care label and dye the fabric. Next I ship the fabric to the sewers who put them together and send them back to me and they go through a last quality control check and then go out to the customers. I have a very active roll in my product but in the future I will be taking a more hands off approach. In the beginning I believe you have to have a more hands on approach until the cost of your time outweighs the cost of production.

The most important thing I had to learn on this journey was that when mistakes are made at the beginning of the process, the whole process is thrown off. Even when you ship something and it doesn’t get there the day it needs to, the whole job gets thrown off. You have to take this into account when you are quoting turnaround times. Also, don’t let loyalty get in the way progress. Sometimes you have to cut it off when things mistakes are continually made because those mistakes cost money and effect your bottom line. You also have to test your sewers before you go with them. You do this by giving them a completed sample and have them make another one for you. If the quality is good and the price is right, you can set up your sewing through them. If the quality isn’t there and/or the price isn’t right, you gotta move on. I’ve had to learn a lot of this the old fashion way of trial and error and making many mistakes but as long as you can recover and learn from those mistakes and keep pushing forward, you should be able to accomplish what you wish to accomplish.

Contact Info:

- Website: www.andahoodie.com

- Instagram: @andahoodie

- Facebook: Andahoodie

Image Credits

Photo 1: Tristan Garcia and taken by Priscilla Ellerbrock Photo 2: Abby Kuhtz and taken by Mary-Anne Douglas Photo 3: Cynthia Pineda and taken by Priscila Ellerbrock Photo 4 Syelus Sells and taken by Charles Sells Photo 5: DeAndrae Douglas and taken by Priscilla Ellerbrock Photo 6: Cherene Johnson and taken by Priscilla Ellerbrock Photo 7: Josh Wilson and taken by Nicole Simes Photo 8: Keola Park and taken by Megan Park Very 1st photo on fire engine is DeAndrae Douglas taken by Michael Ressler