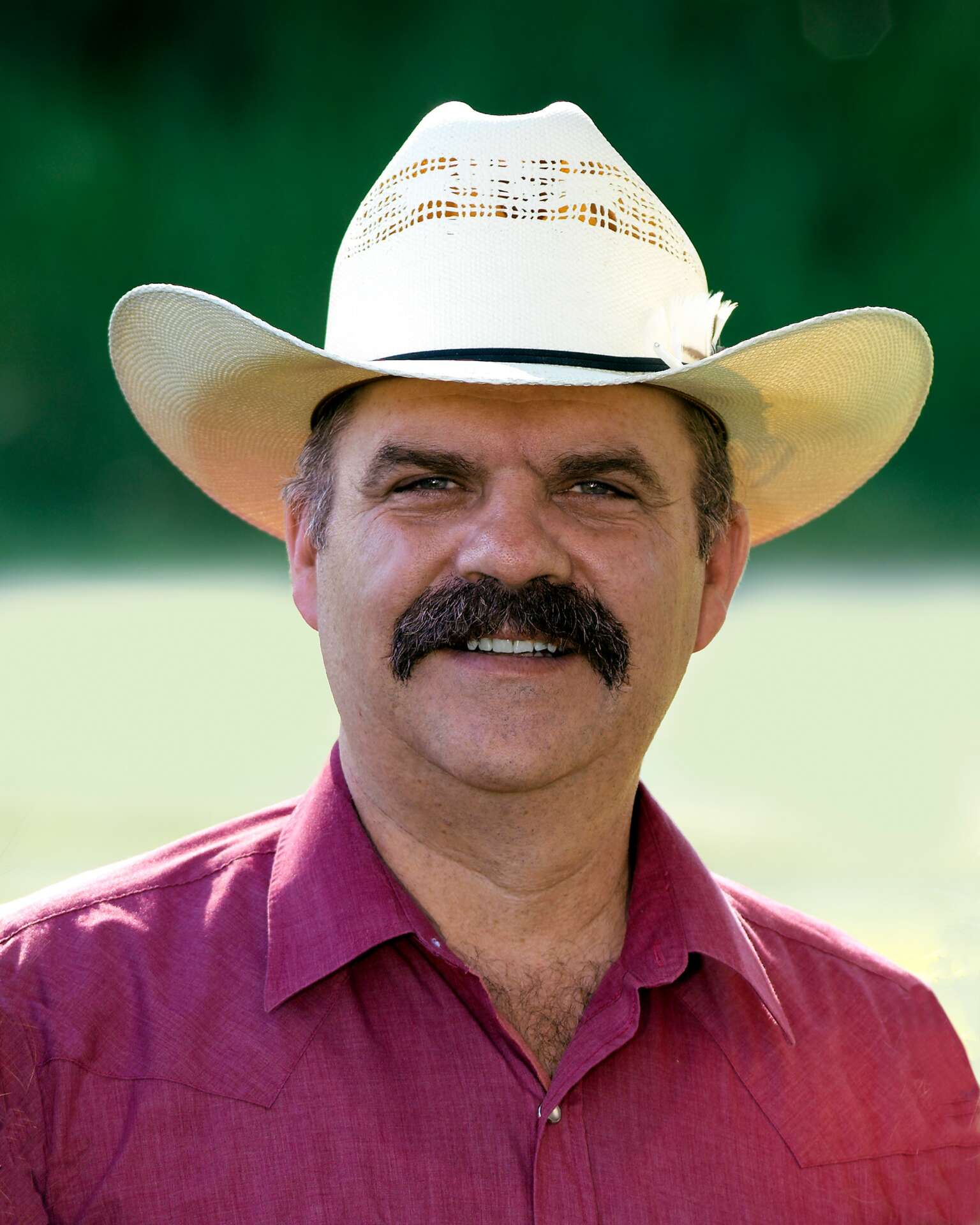

We recently connected with Bill Briggs and have shared our conversation below.

Bill , appreciate you joining us today. So let’s jump to your mission – what’s the backstory behind how you developed the mission that drives your brand?

Close to twenty years ago, my ol’ cowboy grandfather came to me one day with a crisis. He was in his mid eighties at the time and his hand tooled leather belt was worn to the point that it was about to break in half. He had worn this belt every day for at least twenty years. He was really upset because, as he explained to me, he had been searching for over a year, to no avail, for someone to build him a new hand tooled belt. In all my life growing up around this man, I had never seen him without a leather belt on; it was a required piece of his daily attire. He asked me if I could help him. So I searched around and inquired with everyone I knew who might know of a custom leather belt maker. I was “skunked” as well. Finally, to avert the crisis, I convinced my cousin Dan Mayer, a master custom saddle maker, to make Grand Dad a new belt.

Throughout that process, I began to realize that most of the old leather crafters, specifically the custom belt makers, had faded out and were no longer available. Instinctively I knew there was still a lot of demand out there for authentic, hand tooled belts, particularly among the older generation. Now, it is critical to understand that we are not talking about an average, factory produced leather belt. Cowboys and westerners of my grandfathers generation were very particular about the quality and appearance of the belts holding up their britches. First of all, the leather was genuine, vegetable tanned cow hide . . . and thick enough and strong enough to hold up to day to day wear and tear of the working man’s lifestyle. These belts were also deeply hand tooled with floral and geometric patterns to provide some style and reflect the historical working cowboy culture of the West. So there was a lot of artistry involved in the creation of these belts. In most cases, to the discerning eye, the actual belt maker would be recognized by the pattern and style of the tooling; just like any other artist.

Growing up in the culture, I understood all of this and how important these works of art were to the historical culture. In 2011, my family and I set about creating a leather craft business to fill that incredible void and provide people with a genuine hand tooled belt that was a true representation of all of the qualities previously mentioned. To keep the tradition alive, these belts had to be made from the best leather money could buy for durability and also be tooled in a fashion that would be visually attractive and reflective of the old authentic styles.

The Briggs family represents six generations of actual authentic working cowboys. None of those cowboys would have been caught dead without their belt on. With every custom, hand tooled belt we make, we try hard to provide our customers with a true, traditional work of art that also serves the practical purpose of it’s design.

Awesome – so before we get into the rest of our questions, can you briefly introduce yourself to our readers.

In 2011, in the small town of Cokeville, WY, in a conversation around the evening dinner table, our family of seven made a decision to start a family business. I had been aware for several years of a significant void that existed in the custom hand tooled leather belt category. We resolved to create a business that would serve to fill that void to the best of our ability. Our family heritage was one of cattle ranching and authentic western culture so we understood the value of genuine hand tooled leather products and the fact that they are actually a work of art. Convinced that there were still a lot of people out there who had a desire for quality leather craft, we decided to focus our efforts on custom made belts.

Even though we had been exposed to the craft, none of us actually had any skills in belt making. Furthermore, we had never been actively involved in retail sales or marketing. So the decision to start a family business literally from scratch was a fairly bold move. I had $700.00 in cash saved up from some professional guiding I had done. With that cash, I purchased some leather belt blanks, a leather tooling manual by the famous Al Stolman, and the basic tools I would need from Tandy Leather. I have a cousin, Dan Mayer, who is a world class saddle maker. Even though lived about three hundred miles away, he served as inspiration and sent me some critical hand tools. I ruined a lot of good leather for several months in my attempt to develop my tooling skills. It was very discouraging at first, but I just kept at it and eventually, I saw significant improvement in the quality of my tooling. Next I had to learn how to build a web site and how to effectively publish it with the search engines in order to go directly to the people to sell our product. Those two projects proved more difficult than perfecting the tooling, but eventually we had success there also. Our two sons, John and Roland soon followed in the craft and have booth become master belt makers. My wife DeAnn jumped in and helped with every aspect of the business other than the actual tooling. Our three daughters, Kallie Kay, Bethaney and Adrianna have all been involved and have helped a lot with the technical or computer based aspects of the business and some of the actual finish work on the belts.

Custom hand tooled leather belts are a very unique and rare product item. As mentioned before, they are definitely a work of art due to the fact they are produced with individual hand tools and swivel knives. There is a great deal of hand work and unique artistry involved. No two of these belts are the same. As the floral patterns are laid out and installed, the elements of the design have to be crafted and changed to fit the length of the belt. Each belt can take as much as six to seven hours of hand work to complete.

The quality of the leather we use is a very important aspect of each belt. It has to be both strong for longevity and flexible for comfort. If a person is going to invest hard earned money in a belt designed to be unique to them, it definitely needs to last a long time. Because the belt is unique to the purchaser, they grow fond of their belt. It becomes an important part of their daily apparel; sometimes these belts are even passed down from one generation to the next. I still have one of my grandfathers original hand tooled belts that he had made as a young man. He wore it for at least forty years. It sits on my work bench to serve as inspiration.

One of the important things we try to point out with respect to our product lies in the fact that back in the 80’s and 90’s the larger corporate retailers that were selling belts transitioned from genuine, American made cowhide to manufactured or synthetic “faux” leather. Why did they do this? Simply because actual cowhide or vegetable tanned leather is very expensive and harder to come by in volume. Because of this change, belts became less expensive and would also wear out a lot faster. Most retail belts are now produced in factories overseas. In the early stages of our business, I had a good friend come to the house. He was a working man and very large in stature. He brought a box of four belts with him that he had purchased over the past year and a half at retail stores. All four were torn at the adjustment holes and were in various stages of coming apart. He handed me the box and asked, “Can you fix this problem? I need a belt that will last more than six weeks.”. We built him a belt. Ten years later I checked with him and he was still wearing that belt. Mission accomplished.

Because we are the product of many generations of working cowboys and cowgirls, we value authentic, well made cowboy gear. Belts are a big part of that tradition. There are a lot of great custom saddle makers out there – far fewer good custom belt makers.

With our brand of Lone Tree Leather Works custom belts, we want our customers to enjoy the daily use of the belt for at least fifteen years. Now of course, genuine leather requires good care in order to last that long and we do try to teach our customers how to effectively care for their belts. For each of our customers, we want to create a belt that is unique to their personal style, traditions and culture. Even so, most of our belts are created within a traditional Western theme.

When we first started our business, it was important to us to design and create our own unique floral tooling patterns. This was for two reasons. First, we didn’t want our success to be accomplished on someone else’s work or creation. Second and maybe most importantly, we wanted our tooling patterns to be recognized and associated with our business, within the industry.

How’d you build such a strong reputation within your market?

The answer to this question is two fold: First and foremost is “Quality of Product” Second is “Customer Service”.

It was absolutely vital to us that we develop the ability to produce a custom leather belt that was as good in quality as money could buy. Having grown up in the authentic cowboy culture, we were fortunate to know the critical elements of a high quality belt. We needed genuine vegetable tanned cow hide leather in 10. oz thickness. It needed to be of a special “tooling” grade so that the tool marks and artistry would hold up to daily wear and tear. Also important was in finding leather that had the color tones or dye installed during the tanning process so that the color was not going to rub off or fade with time. Then we had to develop our tooling skills to meet or exceed our competition. We then added other features such as painted back grounds, stitched edge borders, buck stitching and a variety of buckles and conchos to add variety and uniqueness to each belt. About three years into our enterprise, we implemented laser engraving to be able to customize our belts with names, initials, cattle brands and other symbols so that our customers could personalize their belts. Lastly we discovered a finish product called Black Rock Leather N’ Rich that we use as the final finish coat on our belts. This amazing product softens and protects the leather, enhances the color tones and generally really helps extend the working life of the belt greatly.

Really good customer service was our next highest priority. Because we are selling our belts to individual people and each order is unique, it allowed us to interact with the customers on a very personal basis. Many of the orders were placed over the phone in conversations that allowed us to answer questions and get to know our customers personally. As a result, we remember them for future, return orders. I’ve had so many customers comment that they simply could not believe they were talking to the business owner/craftsman. Also, we have always offered a 100%, no questions asked, money back guarantee. If within three days of receiving their belt, the customer decides, for whatever reason, that they are dissatisfied with their purchase, they return the belt to us and we refund their money. That takes a lot of courage and faith in your product but we felt it was critical to back up our product. In just over 5,000 sales (orders), we have provided full refunds to less than 30 customers. We are convinced that some of those refunds resulted from buyers remorse with respect to the amount paid and not due to the quality of the belt. And . . . as anyone in retail production / sales will tell you, some people are just impossible to please. . . . just the nature of the beast . . . . . so to speak. In every interaction we have had with our individual customers we have tried so hard to lean towards the customer or give them the benefit of the doubt . “The customer is always right”. I know this approach has paid big dividends and earned a lot of customer loyalty. Our company theme is that we want every single customer to be very satisfied with their belt. Every customer . . . not 80% of our customers, . . . . every single customer. If that means rebuilding a belt due to a customer mistake, we have done that on so many occasions. Imagine the anxiety of a working woman who saves her money for months to buy her significant other an amazing, highly personalized gift . . . . only to discover when the belt arrives that the size is off four inches. Personally, as the business owner and belt maker, I am going to cover that for her. Individual people matter very much to us.

Can you share a story from your journey that illustrates your resilience?

When the Covid 10 pandemic hit, we were about ten years into our business and had just achieved that magic threshold where you start to stabilize and realize that your business has earned it’s place in the market. When the pandemic hit, our sales dropped severely. For two months our sales probably averaged 10% of normal. We were heartbroken and really stressed out that something completely out of our control was threatening to end our ability to continue.

After many family meetings and discussions (and heartfelt prayers) it occurred to us that we had a very valuable customer base and some customers that were very invested in our company and product. In fact, we believed that most of our customers had an actual vested interest in our survival . . . if for no other reason, so they could order more belts in the future.

In our customer data base we had email addresses for all of our past customers. So we sat down and drafted a message describing our situation and just asking for support – specifically saying that if any of them were thinking of ordering another belt that now would be a great time to do it.

The response we received was overwhelming and so rewarding. Over the next thirty days after the email went out, we received dozens of orders – enough to rebuild our cash flow and get right back to work filling orders. It was so rewarding and amazing to realize that our customers had our back and were invested in our survival during a very difficult time for so many people.

Contact Info:

- Website: www.bigskybelts.com

- Instagram: @lonetreeleather

- Facebook: LoneTreeLeather

- Youtube: Lone Tree Leather Works

- Other: Business Phone: (406) 285-2521 Email: [email protected]