We’re excited to introduce you to the always interesting and insightful Aquinas. We hope you’ll enjoy our conversation with Aquinas below.

Aquinas, thanks for joining us, excited to have you contributing your stories and insights. Before we get into specifics, let’s talk about success more generally. What do you think it takes to be successful?

Success is a result of positive action. It’s choosing to start, taking a step forward towards the accomplishment of a goal that you may have. That goal can be as large or small as you have need. It may take one step or a hundred. The key however, is to move forward on the thought, one step at a time; brick by brick. It’s choosing to continue forward on the journey, overcoming obstacles, solving problems, doing things you haven’t done before, asking for help and delegating tasks and keeping the end product in mind.

For us, success means delivering quality, utilizing the best techniques over speed, being detailed oriented, flexible, and circling back with the client to make sure they are satisfied with the product.

In our creation process we measure success in stages within a crossfunctional environment, using established project management standards as a blueprint starting from the client brief all the way through the installation and follow up. We ask a ton or questions initially and listen to our clients needs and concerns. We develop quotes and designs to make sure they are a reflection of our clients vision. Then we move to production. Many times we’re doing something new, mistakes happen, failure happens but we continue to push forward while documenting the process’s, lessons, and solutions. That part is very important! This is how we build our SOP’s. Once production is completed we’ll schedule time of the delivery or installation. We’ll follow up with a field visit report detailing what took place.

To be successful one has to have a “can do” attitude. I already know that I can do anything that has been done already. If I want something and I put my energy towards it, that thing I want I will have from a material sense. Seek and ye shall find.

Now more than ever, for me to enhance my success, I choose to become even more intentional, less wasteful of my time. Things which limit me, slow me down, serve as distractions they only get a few minutes of my time now. Whereas on the filp side, things that expand my skillset, knowledge set, things that build more neural connections has a higher priority.

Growing up I’d hear from the old heads that “There’s more than one way to skin a cat” lol not sure where that originated from but that take home is there’s more than one way to do something.

Awesome – so before we get into the rest of our questions, can you briefly introduce yourself to our readers.

Sure thing, I did 5 years at DeVry, there obtaining a bachelors of science degree in biomedical engineering. I started my professional career as a field service engineer for a well known biotech company. For more than a decade I traveled domestically and abroad providing top level customer service in that field. I installed systems, fixed them, trained end users, trained engineers, managed teams and provided technical support. The experience change my life 180 degrees for the better. I was able to travel, become more cultured, was invited into different circles and rubbed elbows with some high profile and well known individuals in the scientific community. The things I liked most about that position is that it didn’t 100% feel like work. I was my own supervisor essentially responsible for representing the company and maintaining a high level of integrity while getting the jobe done. Everybody I met was amazing.

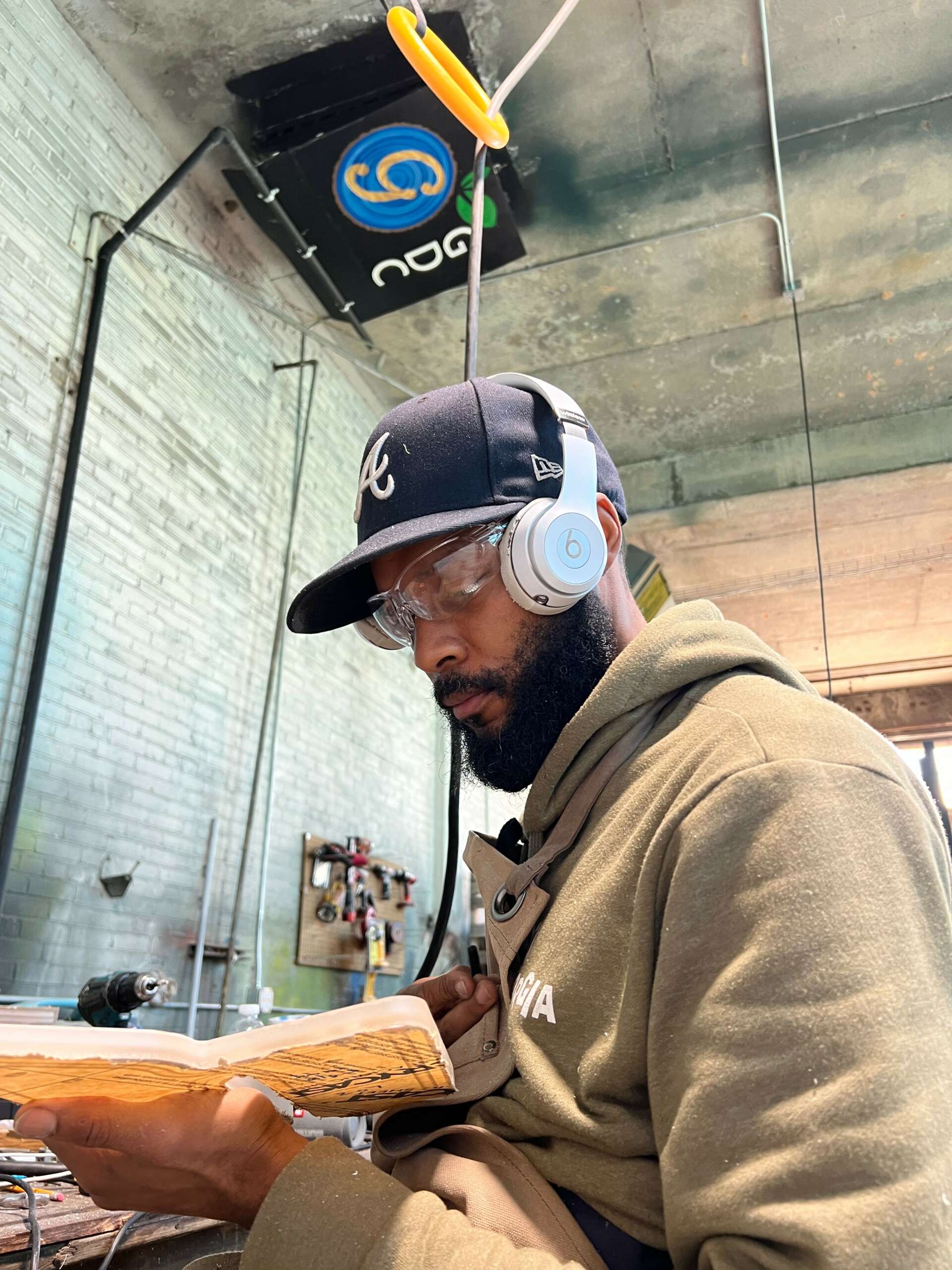

Over the years though I began to think about my own goals and things that I wanted to achieve in life. I was doing good work but was feeling unfulfilled. For a long time I’ve always wanted to invent something, something that I could do on my own and be proud of. At my core, since I was a child I’ve always been artistic and as I grew in my teenage years and into my career my art transitioned from drawing hands, cartoons and people to drawing buildings, sketching out products and technical schematics. At the company I gained experience in working with various robots and lasers and how they helped with my clients workflow. At the time I didn’t know what I wanted to make so I left that part open. I just knew that I needed the tools necessary to make anything. The major tools I started out with at the time was a 3d printer, a cnc machine and some other wood working tools. From there in my basement Grain Design Concepts was born! I figured I’d do some woodwork, make some art and signs then transition into the tech from there. we made few signs, shipped them abroad and from there I knew It was possible. We found a location, and old warehouse with big garage doors and got to work. A few years later in 2021 i decided to leave my company of 13 years and invest that time into manifesting something bigger than myself.

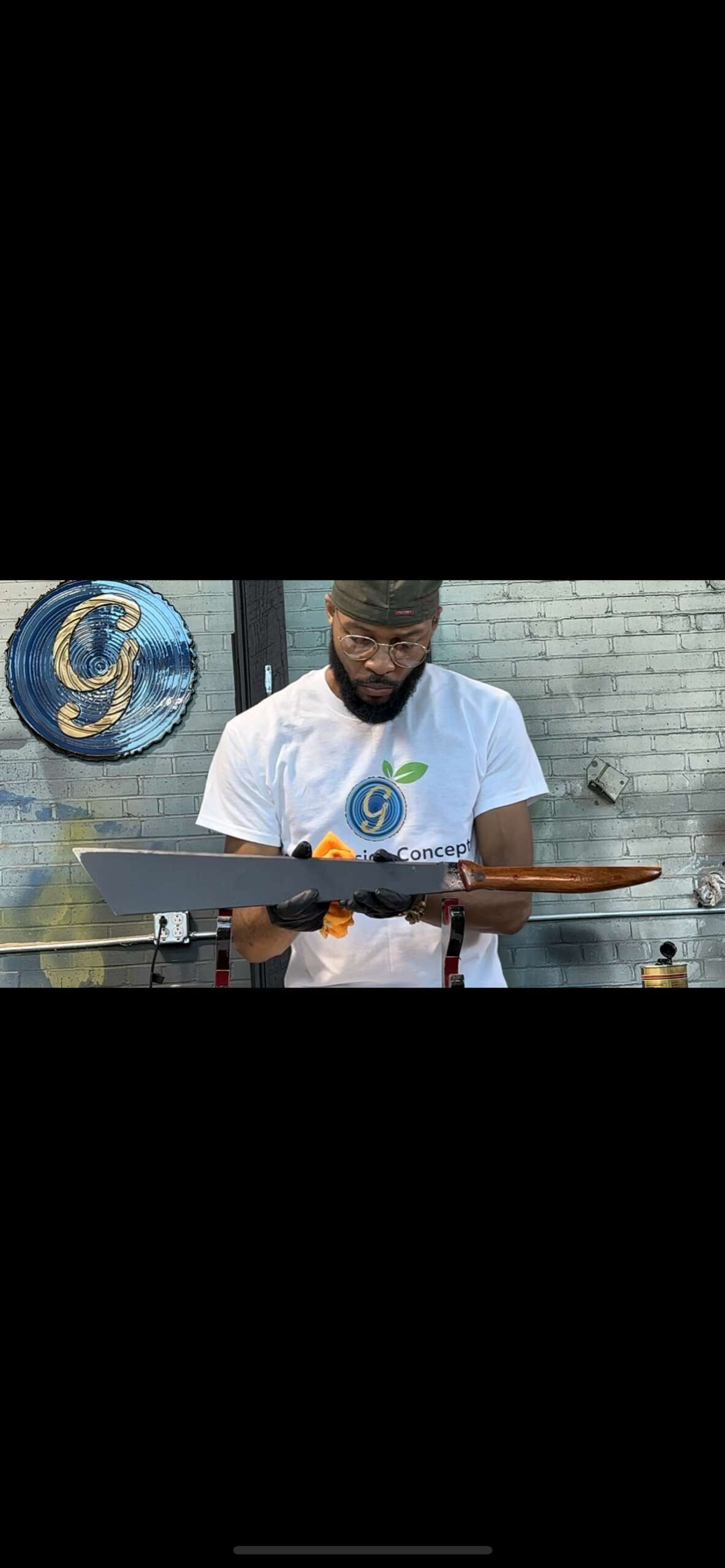

Two years later and many projects completed, today I’d describe Grain Design Concepts, as a creative multifaceted fabrication and design enterprise that specializes in custom signage, unique lighting solutions, prop creation, furniture production, and other innovative design services. We manufacture all of our signs and carpentry works from scratch we also offer installation services of everything we produce. We also excel in 3D design and mockups for art, products, interior decor, and other woodworking projects. Our capabilities extend to offering specialized services such as welding, laser cutting/engraving, CNC services, small batch mfg, automation solutions, educational workshops, Large format print services, vehicle wraps and decal installation.

The majority of our clients right now come to us to create for design elements, to create for them something that fits their space and to be apart of their creation/manifestation process and to see it through is a great feeling and honor!

innovation quality and communication are three values which are at the root of all of our creations. because we intend to make things that stand out, things that last, and we love to build with you through the process and celebrate at the finish line.

Okay – so how did you figure out the manufacturing part? Did you have prior experience?

We manufacture all of our products 95% of the time. We’ve made all types of signage: vinyl cutouts, vinyl on acrylic, led neon signs, back lit signage, cnc engraved painted and stained signs, 3d contoured signage and channel letters. They all start out the same, with an idea and/or a design the client already has. For every product we do research the materials and the “how to”, but the things we haven’t done before we do more research. Youtube University!

Chances are someone has already done what you are trying to do so it’s our job to become knowlwdgeable of the in’s and out’s of a process.

Many times, it’s not feasible for me to do all of the legwork and sometimes a machine may be down. To sustain the project timeline I rely on my partners of the needed discipline. We have graphic designers, print specialists, electricians, engineers and other contractor we partner with. How I’ve come to make these connections is through asking my peers and searching the web then through trial and error we are able see who we want to continue to build a relationship with.

Some lessons i’ve learned in manufacturing are: 1. use scrap material until you can dial in the specs you want before utilizing the finish material 2. get multiple quotes for a job that you’ve delegated and know what the differential factors are. 3. keep track of the time, materials used and cost invested in the mfg process. 4. Make the jigs needed for faster production.

What’s a lesson you had to unlearn and what’s the backstory?

Quoting a project appropriately so that you can complete the job in the timeframe agreed upon and see profit was tricky for me initially and in some ways we’re still unlearning some behaviors. In the beginning I would do everything on my own but then I had a complex atrium sign to make and I quoted it from a perspective of me doing it alone which was a big mistake. Because I didn’t factor in that I needed 4 additional hands I ended up in the negative at the end of the project. I also ended up putting more time into the project after the completion date. I learned to factor into the quote the additional people I’d need upfront. If there was a project that needed work in 4 different areas then I know i need to quote it with those individuals as if how much I would pay them to do the job and create a large enough budget for materials. Take your time and don’t rush the quote, get all the information and ask as many questions that you can ask to be as informed on the project as possible. To get my quoting in check I watched some educational videos and asked other business owners about their process.

Contact Info:

- Website: www.graindesignconcepts.com

- Instagram: graindesignconcepts

- Youtube: graindesignconcepts