We recently connected with Adam Godet and have shared our conversation below.

Adam, thanks for joining us, excited to have you contributing your stories and insights. Let’s start on the operational side – do you spend more of your time/focus/energy on growing revenue or cutting costs?

Cut costs. I intend to remain a one person business with part time contract help. Growth costs a lot of money and I spend my time trying run my business as smartly as possible.

Some strategies: I recently started offering woodworking classes in my home studio. There is really no overhead with teaching in this way–just time and I am able to offer a service to the community.

I also worked out of shared co-op. We share a huge workspace and all of the power tools. This reduces my rent to about 50% of what my colleagues in solo shops pay.

Cutting costs also means spending money to save time. I recently outsourced part of a small batch manufacturing job to a fellow woodworker with a CNC. This saved me multiple days of my own time and that of an assistant.

Revenue only matters if profit is going up too. And the fastest way to profits is cut costs.

Great, appreciate you sharing that with us. Before we ask you to share more of your insights, can you take a moment to introduce yourself and how you got to where you are today to our readers

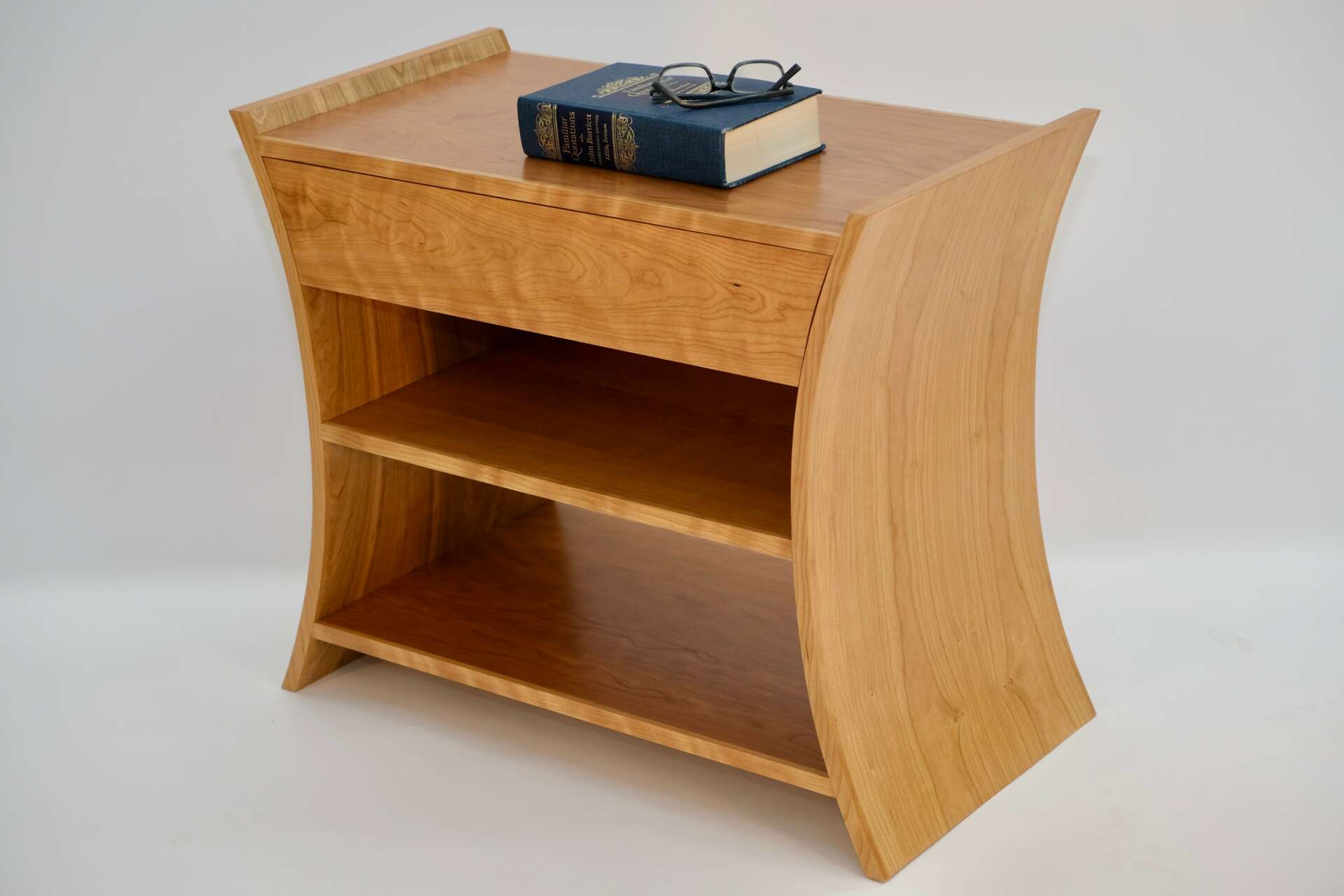

I design and build custom hardwood furniture. I love working with clients to design exactly the piece they are looking for. While I have my own aesthetic and believe that people know my work when they see it, I work in many different styles. I try to take a collaborate approach to design. While I will make the piece by myself, the customer lives with it for a very long time. I want to make sure we design exactly what they’re looking for both in terms of form AND function.

Most clients seeking custom furniture have a specific need for a specific space. Solving this need is where I get really excited. If you need a table that will fit in an awkward space and do some unconventional things…you’re not going to find anyone more excited than me to help you solve that puzzle!

I tend to work, primarily, with traditional tools. Really, I’ll use whatever the right tool is for the job, but as the industry moves toward CNC’s and digital design, I like older machines and traditional hand tools. I take a lot of pride in handcut joinery (especially dovetail joints) which I cut using a handsaw and a chisel. There are probably 12 ways to do it faster, but I’m not interested. I enjoy the process and the look of my joints when I cut them this way.

My motto with my work is “better, fewer things”. I don’t intend to grow with a team of employees or with automated machines I aim to make 15-20 really nice pieces each year. Each one will be made with all of the clients’ needs in mind and with attention to every detail.

How I got into the industry.

When people ask how long I’ve been woodworking, I usually say, “pretty seriously since 2009, but I’ve been making things my whole life.” When I was about 7 or so, my dad brought home a small coping saw for me to play with. I had been messing with his tools and scraps of wood for a while and he was supporting my interests. He probably also wanted me to get out of his toolbox. Since the saw has an easily replaceable blade and is not powered by gas or electricity, it was relatively safe. This was the 1980s when people still smoked inside and people threw lawn darts, so he was well within his rights.

Eventually, in high school, I made Rube Goldberg machines as part of an annual Science Olympiad. These were basically over complicated machines that did a simple task; for example, you had to move a ping pong ball into a cup. BUT, you had to include multiple kinds of energy transfers, do it a specific sized box, within a certain time window, etc. This helped spark a love of basic engineering and problem solving in physical space. Skills that apply really well to furniture design.

In 2009, I was well on my way into a government career. I was getting promoted, doing cool things, wearing nice suits. But a general anxiety and depression set in. I kinda felt out of sorts. Ungrounded. Despite having all the things in order (good job, good finances, good relationships, good marriage, etc.). I think a lot of people feel this at various points in life. As I stood back and reflected, I noticed that at previous times in my life I had turned to making things in similar instances. When I graduated college I lived with my parents for a few months before moving to Baltimore. As the move approached, I realized I needed some bookcases and despite never having made a piece of decent furniture, I decided to build my own. When I went to graduate school, I built myself a desk for my 9X9’ bedroom in a group house. First place in DC? Built a bunch of furniture for the tiny “English Basement.” In all of these periods of tumult and change, I found myself making things. Kind of returning to my roots, in a way; roots of childhood and perhaps even more deeply, just basic human roots.

My job sent me overseas for the summer and I read Matt Crawford’s book Shopcraft as Soulcraft This book gave me an intellectual framework to help understand the general malaise I was feeling and was the kick in the butt I needed to get back into a shop. I came home, signed up for an Adult Ed class, and never looked back. I remained a federal employee for years as I built skills and business and finally went into woodworking exclusively in 2021

Can you tell us about a time you’ve had to pivot?

I’m actually coming off a recent pivot. For years, my business was split between a home goods line that I sold in retail locations, craft shows, online, etc. Throughout 2022, I saw demand for these tried and true designs slowly drop. The Downtown Holiday Market in DC, which I had done for several years saw a 40% drop in sales from the year before. While this could have been chalked up to just a bad season, I took it as an opportunity. While I intend to continue with this line, the realization I had was that I was trading off a lot of time and attention (and administrative overhead) to keep that side of the business healthy and going. It had no guarantee of certain sales numbers (especially at the holiday market). And, my heart is in making furniture.

I took this opportunity to launch a woodworking instruction program out of home studio. My goal is to supplement money from furniture sales with teaching. If the teaching goes well, I hope to expand offerings and possible partner with other local woodworkers to offer more opportunities to learn woodworking in the Washington, DC area.

What else should we know about how you took your side hustle and scaled it up into what it is today?

I was making things as a side hustle for over a decade before it become my exclusive income source.

There are lots of jokes about how you make money in woodworking. My favorite is how do you make $1million woodworking? Start with $2million.

It’s not as bad as all that, but like any small business, it’s challenging. And being an artisan is perhaps an added challenge.

I took it slow and set up a long term strategy. My wife and I followed principles of frugality espoused by the FIRE movement (Financial Independence, Retire Early). To be clear, this is not retirement. I work harder than ever. But we wanted to have a really solid financial foundation before I took this financial risk.

While I did that, I was able to really focus on building skills. I did not focus on growing a huge client list or on basic business principles (I wish I had focused on the latter). I spent time making projects for clients who were incredibly patient. They got good deals because I didn’t fully understand the market. To be fair, they waited a long time for their projects too because I had limited shop time.

As my skills improved and I got faster at the work, I had more opportunities to make more things. I went to part time in my federal government job and slowly transitioned to self employment.

Contact Info:

- Website: godetfurniture.com

- Instagram: Godet_Woodworking

- Linkedin: Adam Godet

- Twitter: AJGodet

Image Credits

Photo of me: Shawn Bruce Photo of Dresser: Shawn Bruce Photo of square side table: Shawn Bruce