We’re excited to introduce you to the always interesting and insightful Aaron Lucas. We hope you’ll enjoy our conversation with Aaron below.

Aaron, thanks for taking the time to share your stories with us today Let’s jump right into the heart of things. Outsiders often think businesses or industries have much larger profit margins than they actually do – the reason is that outsiders are often unaware of the biggest challenges to profitability in various industries – what’s the biggest challenge to profitability in your industry?

I think the average consumer is extremely uneducated regarding the production of custom pieces. This applies to the availability of materials, specialty tools needed for the project and the time it takes, not only to design but then to create a piece. For example, a recent commission was for a custom box with an interior engraving. The client wanted 2 different woods for the inside and outside, hidden hinges and a message laser engraved inside. I am guessing that Etsy showed them some beautiful mass produced items, similar in ascetics, for $40 or $50 dollars. These are product made in a factory, with a problem free process, making them in the thousands, meaning all costs are down. The wood for the box was over $100, specialty woods remember, and specialty tools used only on this project costing around $400, already $500 has been spent before designing, jig making and then everything involved in creating the piece, which took over 40 hours due to multiple laminations. I believe this stems not only from a market flooded with low price imports but the fact that schools no longer offer things like shop class, metal class, home economics and the any I may have missed. The average consumer goes into young adulthood with no real concept of the difficulty to manufacture things, much less do a specialty one off. But from my side, how can I justify to someone like that 40 hours of labor and material costs, which would total above $3000 with my lowest “rough style” hourly rate? The answer is that most times you cannot, so typically I do not take on these types of commissions. I prefer to be able to give the customer a good rate and make a bit of a profit. I did end up doing the box though because it was for family.

Aaron, love having you share your insights with us. Before we ask you more questions, maybe you can take a moment to introduce yourself to our readers who might have missed our earlier conversations?

All things wood really. If you can dream it then I can probably make it. I grew up with woodworking and it has always been apart of my world. As I have aged I have refined my craft pushing me into a kind of specialty market. I am always willing to talk and brainstorm as well as trouble shoot with any client, which I pride myself on. I am very proud of the fact that several long term commissions have come to me from International Corporations telling me I am the only one they can find that can make whatever it is they need, pretty cool.

Can you tell us about a time you’ve had to pivot?

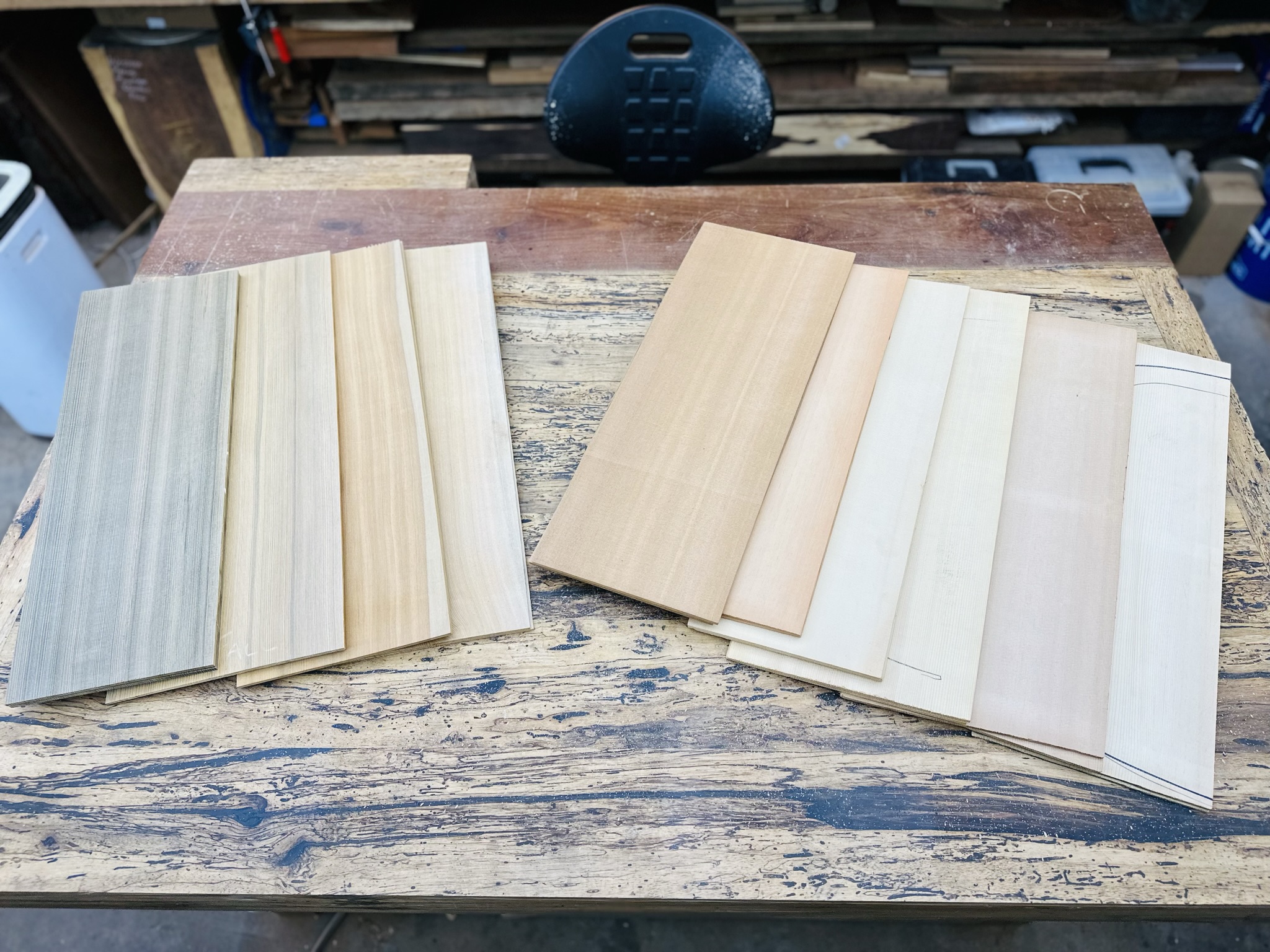

7 years ago with a second child on the way I decided to pivot from running my wood shop to running a sawmill, allowing me more time with my family. A few years later I decided to pivot away from the saw mill and go back full time to my custom wood shop. But upon returning I knew I could not be satisfied with the , to me, mundane repetition of housewares, restaurant service pieces, furniture and brewery pieces. I really wanted to challenge myself and acoustic guitars seemed to be a perfect fit. But upon pursuing that dream I was drawn back into the sawmill world but for the production of instrument grade wood, only this time from my own shop, and I could not be happier. I still try and work at building guitars and hope to do a couple this year but I am not pressuring myself. Life rolls on regardless and I like to think I roll right along with it, always trying to keep my job satisfaction at its highest.

We often hear about learning lessons – but just as important is unlearning lessons. Have you ever had to unlearn a lesson?

Going back to the average consumer not really understanding what it takes to make something and some makers putting insane prices on things was the reason I kept prices low for the first few years. How can the general public even consider making something if they think only the wealthy can afford hand made goods. When I was at the sawmill there was a customer who would buy a slab from us, have us fully flatten and mostly sand it, for under $1000 dollars. Then they would take it to their shop, put a finish on it and attach some metal legs, then sell it for a minimum of $10,000. This to me is false representation to the customer that they actually made the piece, as well as drastically over pricing the piece. At one point I hand carved hundreds of individual beer tap handles and sold them for $8 each, trying to charge what I thought the market could actually afford, silly on my part. These are 2 extremes in the world of makers, drastic under and over pricing. I had to unlearn my grand notions that my products, being affordable, would help drive the dying maker industries. Setting limits and learning to say no when you cannot make a profit, no matter how you look at it, is an invaluable lesson. Being able to educate clients about what is really involved in a project is the key. But you not only need to be brutally honest with the client, but yourself as well.

Contact Info:

- Website: https://www.aaronlucaguitars.com

- Instagram: @aaronlucasdesigns

- Facebook: @aaronlucasdesigns

- Youtube: @aaronlucasguitars

Image Credits

Aaron Lucas