We’re excited to introduce you to the always interesting and insightful Aarav Sharma. We hope you’ll enjoy our conversation with Aarav below.

Aarav, thanks for taking the time to share your stories with us today How did you come up with the idea for your business?

I created my business, Smart Bin AI, after learning about the extremely inefficient and inaccurate ways that current cafeterias and kitchens use to understand their food waste. Initially, I conducted some market research, especially with schools around my area, to understand the current solutions they are using, if any, to identify and possibly reduce the waste. After doing this, I later understood that many cafeterias simply don’t employ solutions to this problem because there is no product/service in the market at an affordable price or that meets customer needs. Immediately, as soon as I reached home after this, I started ideating possible ways I could solve this problem, while keeping in mind that I maintain affordability, and that was when I came up with Smart Bin AI. The best and most affordable solution to identify food waste and take action on how to reduce it.

Aarav, love having you share your insights with us. Before we ask you more questions, maybe you can take a moment to introduce yourself to our readers who might have missed our earlier conversations?

I’m Aarav Sharma, a 15-year-old founder passionate about solving real-world problems through technology. The idea for Smart Bin AI came from observing how food waste tracking in most cafeterias is either inaccurate or not done at all. I realized that despite how common this issue is, hardly anyone was addressing it in a practical and affordable way. That realization pushed me to combine my interests in AI and engineering to design a simple, data-driven solution. After experimenting with different prototypes and approaches, I developed Smart Bin AI which is a tool that helps kitchens and cafeterias accurately monitor what food is being wasted and use that data to make meaningful changes.

Smart Bin AI is a module that applies Artificial Intelligence (AI) image classification to recognize both the type of food wasted and the percentage of the food left on a plate. It uses a deep learning model, specifically a convolutional neural network, to identify patterns in waste and classify food types accurately. The module is set up above a food disposal area, such as a food waste bin, where a camera captures the contents of the waste during a desired time. It will then compile a report with all the food waste information and suggest to the food provider various ways of reducing the waste, such as decreasing portion sizes.

What I provide is simple and focused: a compact module that captures real-time images of food waste, uses AI to analyze what’s being thrown away, and then turns that into a clear report with practical recommendations for reducing waste. For schools and food providers, I am providing them a simple and accurate way to understand what food is being wasted, why it’s happening, and what actions they can take right away. This directly helps them make quick decisions like adjusting portion sizes for specific dishes to cut down waste.

What sets me apart is that I actually built this for real kitchens and cafeterias, not just as a concept. Smart Bin AI is already a proven business model since it has been implemented at an international scale with many schools and colleges around the world using the modules. The system has already been implemented in countries such as Singapore, Thailand, and Costa Rica. I ensure to keep the solution affordable and easy to install, and I make sure the output is something that food providers can use the same day.

Can you talk to us about manufacturing? How’d you figure it all out? We’d love to hear the story.

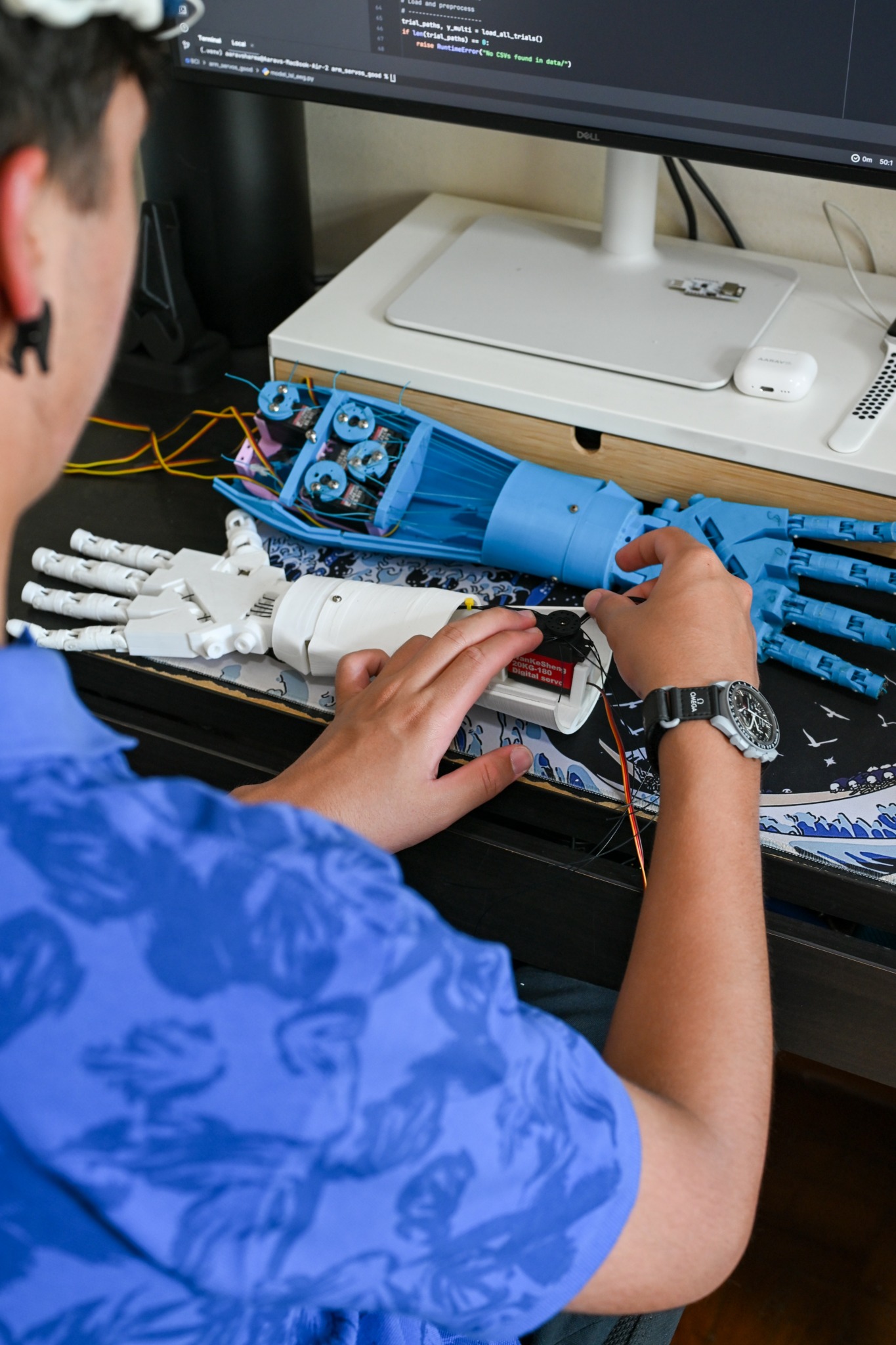

I currently manufacture Smart Bin AI myself because the build needs a high level of precision. Since it combines hardware and software, it is much easier to do it in an environment completely controlled by me. Doing it by hand lets me control small tolerances, check software configurations, and fix issues as soon as they show up.

As there are no third party collaborations, this maintains the affordability aspect of the module. I order the main parts in bulk from reliable suppliers—the camera, compute module, enclosure pieces, mounts, and wiring—and then handle the fitting, calibration, and software setup on my side. This approach keeps costs reasonable while making sure every unit behaves the same out of the box.

As I am still a 15-year-old high school student, I wasn’t experienced in the manufacturing aspect. Over time, I learned by building, breaking, and rebuilding. During the process, I even made the design more modular so parts could be swapped easily, started using simple jigs and checklists to keep alignment consistent, tested at each stage instead of only at the end, documented exact screws, connectors, firmware versions, and calibration steps, and kept extra critical parts in stock so small delays wouldn’t stall the whole build.

Going forward, I plan to work with vendors to scale production. That will free up more time for research, development, and other ventures. At first, I’ll keep sensitive calibration and final quality checks in-house, and once the build is fully standardized, I’ll shift more of the process to a manufacturing partner. This way, I can grow output without lowering the quality that makes Smart Bin AI dependable.

Can you share a story from your journey that illustrates your resilience?

When I first started building Smart Bin AI, nothing worked the way I imagined. The camera alignment was off, the software kept crashing due to low specifications, and the AI model wasn’t recognizing the food types correctly. I spent countless hours debugging small details that ended up breaking something else later. There were moments when I genuinely thought of dropping the idea altogether. But instead of quitting, I forced myself to pause, understand what went wrong, and rebuild each part from scratch without much external support.

Over time, I learned lots; each failed test taught me something new, such as how to make the camera more stable, how to select better training data, and how to make the model faster on my hardware. As I created multiple versions of the module, I slowly started to see improvements until it finally worked exactly the way I wanted. This process reminded me that resilience isn’t about never failing, but it’s really about staying patient when things go wrong.

Contact Info:

- Website: https://aaravinnovate.com/

- Linkedin: https://www.linkedin.com/in/aarav-sharma-

- Other: Business link about Smart Bin AI: https://smartbinai.com/