Alright – so today we’ve got the honor of introducing you to James Gibson . We think you’ll enjoy our conversation, we’ve shared it below.

James , thanks for joining us, excited to have you contributing your stories and insights. To kick things off, we’d love to hear about things you or your brand do that diverge from the industry standard

There are two things that stand out to me. First, we are ruthless when it comes to our design ethos. What I mean by that is that there are a myriad of designs that we have come up with over the years that, no matter how much we like them, we have not made because they do not fit within our point of view. The net effect is that all of our garments, whether part of the same collection or not, are curated. As a result, you can find ancestral links between the very first garments we ever made and our most current garments of today. All of them are born in the same up-country home, if you get my meaning.

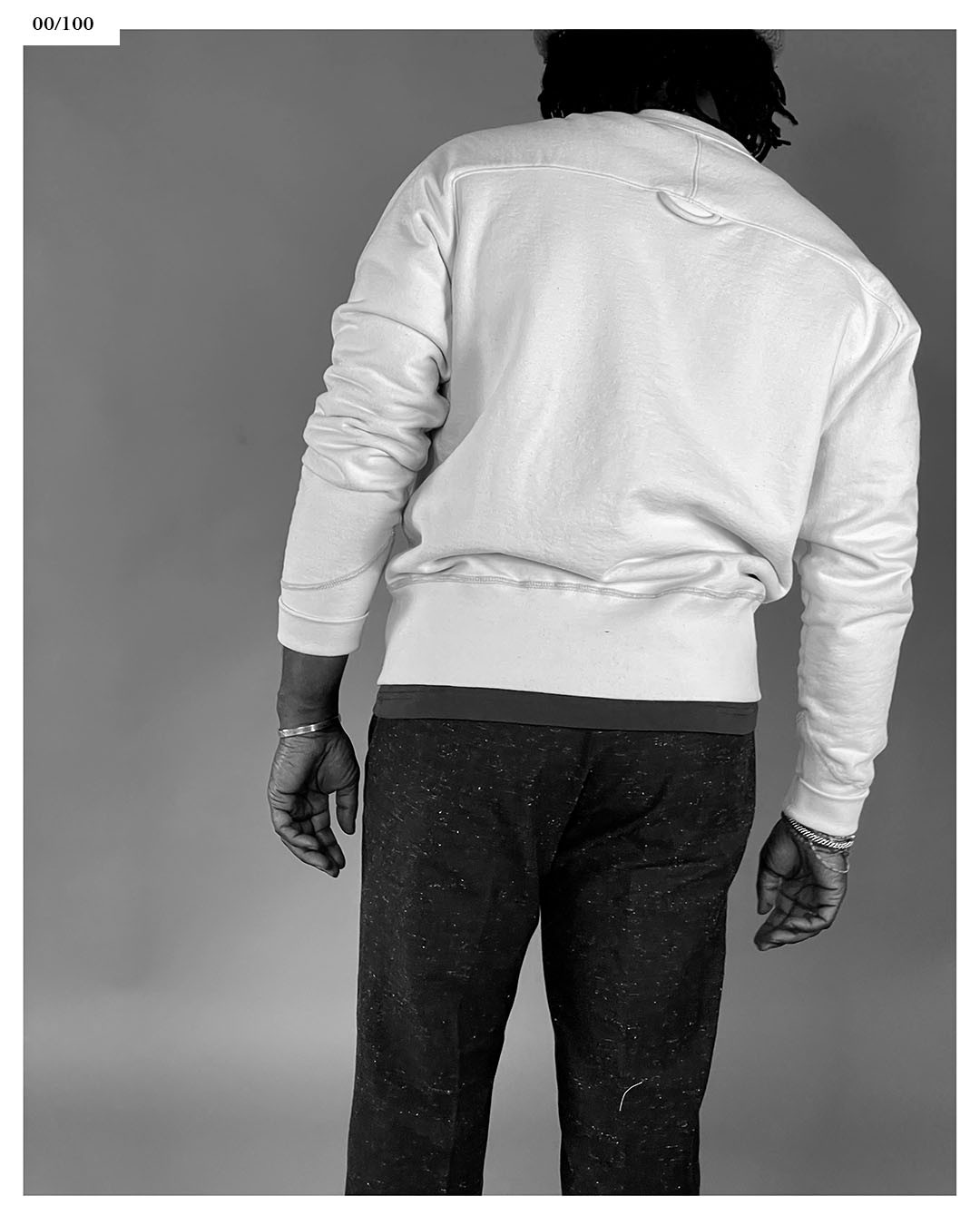

Secondly, we will only make a garment if our design has something singular to offer. There are so many excellent brands out there that make traditional Oxford shirts or sweatshirts, for that matter, that if we didn’t have a unique take on our garments we would not produce them. Our Oxford shirt, for example, has details like a button-collar with a workwear tab and our MRR. utility pocket with a smuggler’s compartment. Likewise, our sweatshirt has a lot of vintage-inspired details like a functional V-insert and scalloped cuffs at the wrist, but it also has an innovative split rear yoke with a locker loop to allow for maximum mobility and comfort.

Our focus is on making garments with functional details and differentiators that truly create a unique experience for our supporters.

James , before we move on to more of these sorts of questions, can you take some time to bring our readers up to speed on you and what you do?

Messrs. R/R is a menswear brand. I have two partners- Que Lynch and Nene Kisseih. Depending on your perspective, we make elegant workwear or functional tailored wear. For example, we make an oxford shirt. Our oxford fabric is sourced from one of the preeminent mills in the world. So, we have taken the elegance of the fabric and the general philosophy of an oxford shirt and coupled them with attributes like a workwear tab collar, a utility pocket with a smuggler’s compartment, and a triple stitched back yoke with a locker loop to turn a closet staple into an altogether new experience.

I think the thing that most sets us apart from others are the edge effects of our garments. In ecology, the greatest biodiversity is found where multiple ecosystems overlap with one another. That increase in biodiversity is called an edge effect. Messrs lives within the overlap of workwear and tailored wear. This allows us to combine the best bits of these disciplines in order to create an altogether new garment and singular experience for our supporters.

What I am most proud of and the most challenging aspect of operating our brand are synonymous- growth. And to be clear, we have not yet reached the summit. We are certainly on an uphill climb every day. I think the best way to understand where you are is to look at where you have been and chart the coordinates of where you want to go. From a backward-looking perspective, we are light years away from where we started. The reason for that is the growth of us as individuals and as a team. Looking forward, we still have a ways to go before we reach our destination. But, as a part of that growth we are learning how to read the stars, how to follow the streams, and I am confident that if we maintain our charted course (and get a little good weather) we will get there.

Can you talk to us about manufacturing? How’d you figure it all out? We’d love to hear the story.

Currently, we manufacture all of our garments in Los Angeles. We work with a couple of manufacturers out there depending upon the garment we are making.

We were bona fide rookies when we started, so the process of locating a manufacturer was an arduous one. It included a lot of late nights researching, cold calling, and taking a lot of meetings to find the right fit for us. And this process is ongoing. We are always looking to leverage new relationships.

Two related lessons stand out for me. First, you need to be as much of an expert as you can on the manufacturing process. It will only make you a better designer and will allow you to have more constructive conversations with your manufacturer about what you want. You need to be able to speak the same language.

Let’s talk about resilience next – do you have a story you can share with us?

I think the entire experience of us running Messrs. has illustrated our resilience. We came into this space relatively cold and have had to quite literally learn on the job. You quickly recognize that having good and creative ideas is not enough. There are so many talented people out there that have amazing ideas. That is almost a given, especially in a place like Atlanta. You really have to be dedicated to operationalizing those ideas and that can be uncomfortable. We have had to remain equally enthusiastic and prescriptive about designing our… sweatshirt in a bar in Amsterdam as we are about sourcing zippers. It all matters and the process you use to execute those tasks likely matters a lot more than merely having an exciting new idea to begin with. You have to relish the mundane as much as the extraordinary because those decisions quite often make the difference.

Contact Info:

- Website: www.messrsrr.com

- Instagram: @messrs_rr