We recently connected with Donald Bless and have shared our conversation below.

Donald , thanks for taking the time to share your stories with us today Can you tell us a story about a time you failed?

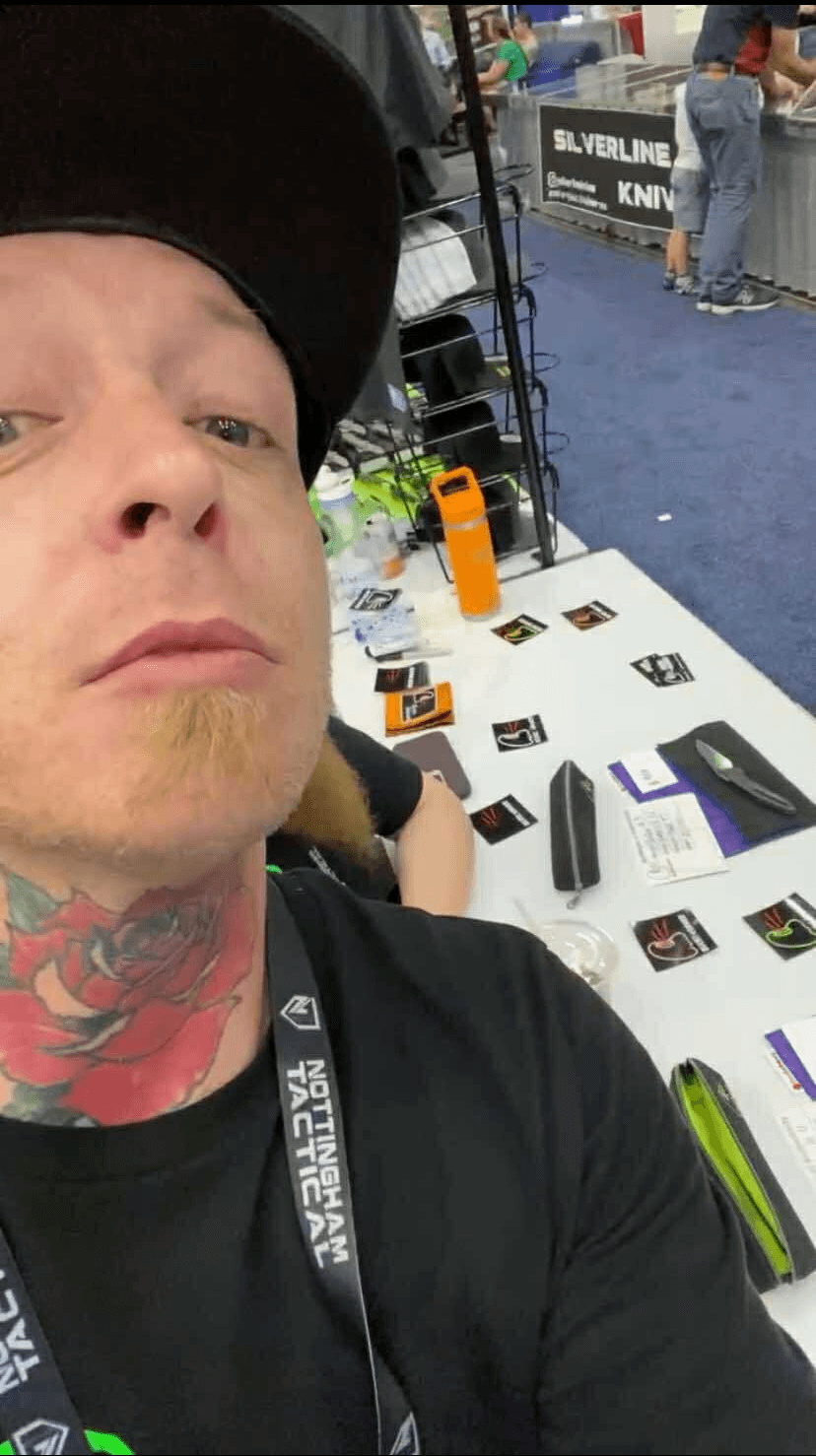

I had started making fixed blade knives when i was still working at the tattoo shop as a side interest/hobby. The shop closed for over a year when the pandemic hit; leaving me with no means of income. With support from my brother I decided to push myself to decided to push my to make knife making work as a legitimate source of income. I designed two folding knives and learned how to make them. Feeling over confident I booked a table at Blade West. Blade West is a custom and production knife show put on by Blade Magazine in SLC,Utah. I made 6 knives for the show. We drove 17 hours from Omaha,Ne to Slc Utah. I had many people; including fellow makers, compliment my design theory. However there were issues with my work that i was just ignorant about. My work wasnt up to the quality for the price i was asking. So after working the 2 day show; I sold nothing. No sales. It was crushing. However I met makers and social media creators that have been my friends since. I also met folks who were willing to teach me how to make my work better. I spent the next year prototyping and learning.

Awesome – so before we get into the rest of our questions, can you briefly introduce yourself to our readers.

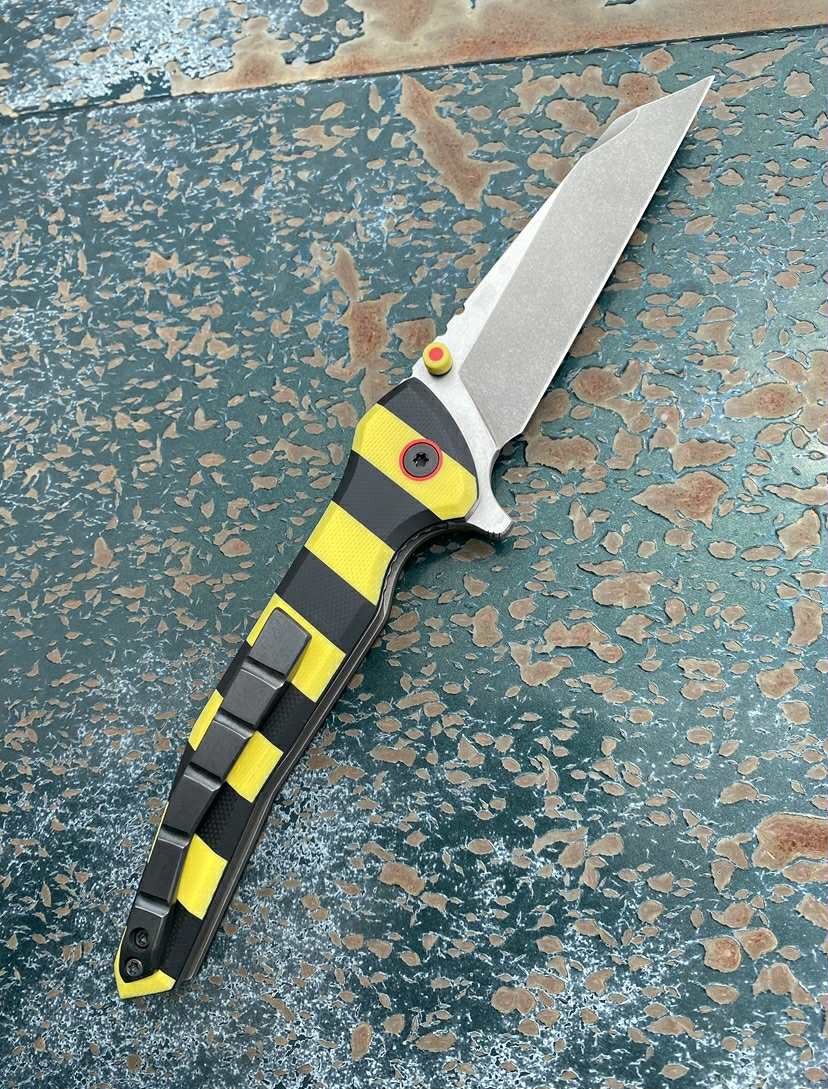

I pierced and tattooed at American Tattoo for 18 years until the pandemic hit. After losing my job due to the pandemic; I decided to try and make knives for a living. I have always been an advocate of carrying a folding or fixed blade pocket knife. I got my first at 5 years old; I still have that one. I started making fixed blades while still working at the shop. The first tool I bought for the hobby was heat treating oven. I decided if I couldn’t do every process of making a knife; why do it. So I began learning how to heat treat steels to make them hard enough to be a knife. At that time I was using metal hand files to shape the blades. I learned hoe to file them rather quickly but that process is very slow. I bought a proper 2×72″ grinder to speed things up; also as that is the standard machine for knife making. At this point i was pretty savvy with heat treating and building a complete and functional knife. I started selling them around my city; by word of mouth and in a couple local retail stores. Next challenge was folding frame locks. I spent two years learning how to build folders as mentioned previously. Folders were always the end goal. I make high end frame lock folding knives as well as fixed blades( pocket/hunting/kitchen). I fell I set myself apart from the majority by my design language and building approach. I make everything rather manually. No milling machine and no cnc machine. MY designs are not only inspired by other makers but also my love of sci fi films, tattooing, skateboarding culture and I’m sure others I’m forgetting at the moment. My flagship model, the Ripley is named for Lt.Ripley from the Alien franchise. Non traditional and highly functional are my loose thoughts when creating a model.

Im also very active with the knife community online. I go live on YouTube solo when Im in the shop making and constantly interact with the folks in the live chat. I also join other enthusiasts/content creators on their live shows.

Im most proud of my attention to detail and symmetry and communication with my clients. Also the fact that I have learned to make a knife by hand that looks like a machine made it.

Contact Info:

- Instagram: https://www.instagram.com/blessknives/

- Facebook: https://www.facebook.com/donald.bless

- Youtube: https://www.youtube.com/@BlessKnives

- Other: e-mail: [email protected]