We caught up with the brilliant and insightful Rob Campbell a few weeks ago and have shared our conversation below.

Rob, looking forward to hearing all of your stories today. Before we get into specifics, let’s talk about success more generally. What do you think it takes to be successful?

The key to success is understanding that the concept itself is fluid and self-defined. Many folks measure their success by the numbers on their financial spreadsheets or the size of their warehouse. I take an approach that encompasses many different metrics. Do I feel creatively satisfied by the work? Am I receiving positive input from my friends/peers? Am I making an impact in my community? Do people like me? Do they REALLY like me?

I started screen printing in a very typical way: buy some used equipment, learn the ins-and-outs in my basement, and upgrade my gear/space whenever possible. I did, for many years, spend too much time feeling the pressure of “NEVER STOP GROWING YOUR BUSINESS”. The narrative amongst other small business owners was always to keep pushing: first employee, bigger space, 5th employee, fancier equipment, 50th employee… and so on. Eventually, I learned that it’s perfectly fine to plateau; to reach a point where you’re making some money, your stress level is manageable, and your commute is 15 steps from your door to your garage. I’m sure I could feel an even greater level of capital S Success; it’s not like I’m at the tippy-top of that particular mountain, but in order to keep moving, creating, and growing, I often repeat my mantra that most perfectionists will be unhappy with: GOOD ENOUGH – onto the next thing.

Rob, before we move on to more of these sorts of questions, can you take some time to bring our readers up to speed on you and what you do?

I originally started screen printing out of pure curiosity and a little bit of stubbornness. I was involved in various creative endeavors (making short films and doing some various stage-related projects). Somebody was offering a screen printing workshop in the basement of their store and I mostly wanted to learn so I could make shirts for my film collective (we called ourselves Cinema Queso). I did approach one screen-printing supply shop to see if they had some sort of starter pack, and I’d be lying if I said their dismissive brush-off didn’t increase my desire to learn the process.

I started printing for other people: comedy troupes, bands, some small businesses, etc. I would upgrade my equipment whenever I could afford to. My big advice: the faster a young printer can invest in less-frustrating equipment, the better (although there probably is something to be said for making every possible mistake along the way). I’m still upgrading certain bits, when I can, but nowadays I am more likely to invest in new technology that piggybacks onto what I’m already doing. I now have a laser-cutter, a sticker printer, sublimation, and a 3D printer. Some of those definitely get more use than others, but it’s really fun to have so many different formats available to me.

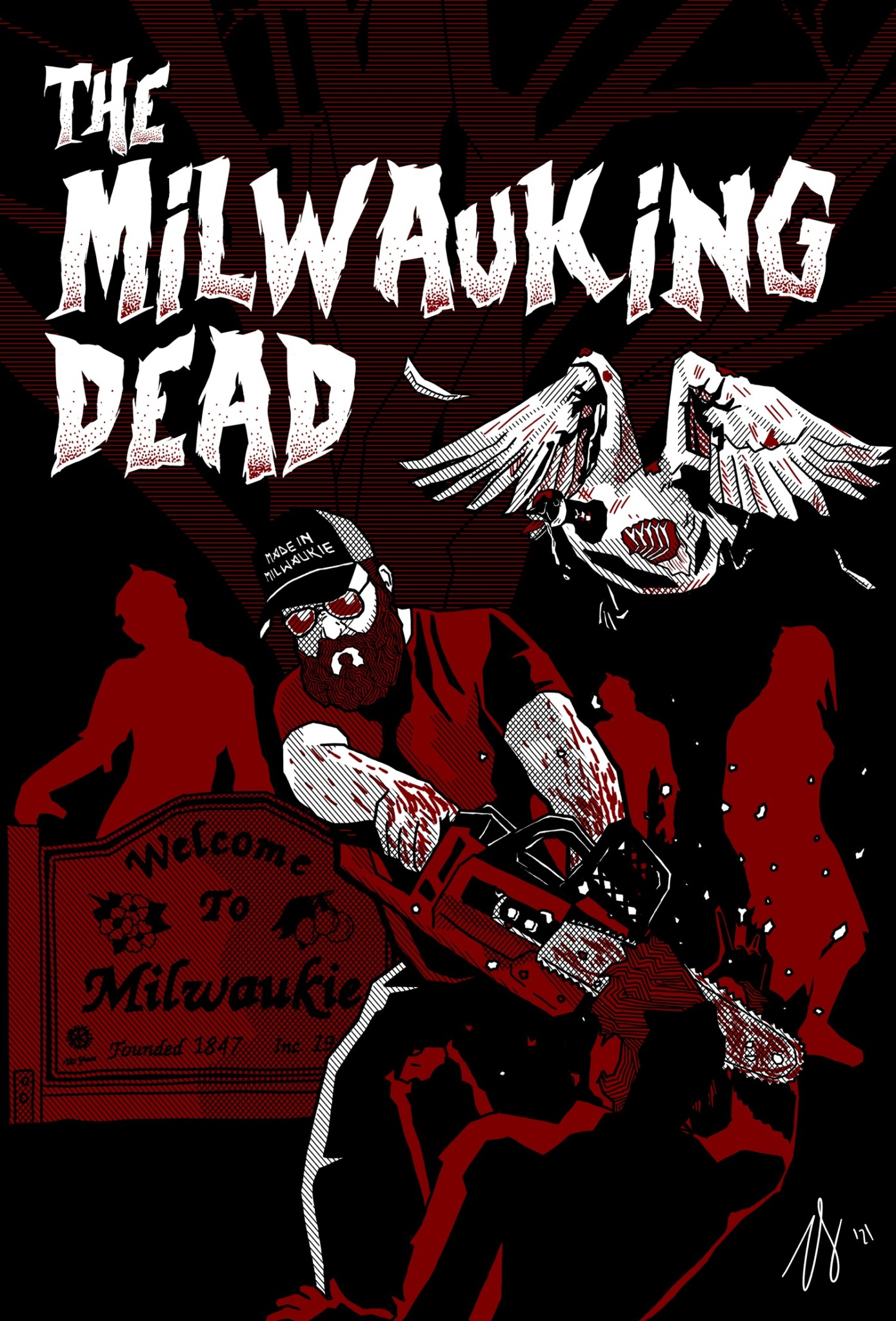

I now have essentially 3 different businesses: Milwaukie Shirt Co (for when I’m printing for other people), Shirt Nerdery (for when I’m printing pop-culture-y stuff to sell online or at comic cons), and, with my business partner Chris Haberman, Made in Milwaukie (a retail store to sell my own line of hyper-local apparel as well as local artist’s work on consignment). The retail store is a good example of “success” that doesn’t have to be super-profitable to feel successful. The store makes a small amount of income, but offers a great opportunity to connect to the community and help support/encourage local artists. It’s very satisfying.

Does your business have multiple or supplementary revenue streams (like a ATM machine at a barbershop, etc)?

I have quite a mish-mash of revenue streams. At first, it was simply: buy blank t-shirts – print someone’s logo onto it – sell it to them for more than I paid. I but blanks for 3 bucks or so; clients get printed garments in bulk for roughly $6-$10 each.

Before long, I started printing my own designs to sell at street fairs, holiday bazaars, or comic cons. I would start to gather other like-minded artists to send me their designs and give them a cut of the sales.

At a certain point, I was trying to capitalize on designs focusing on my hometown (Portland, Oregon) and that was doing ok, but it wasn’t until I moved back to my REAL hometown (the suburb of Milwaukie, Oregon) that I decided it was smarter to aim for being a big fish in a small pond instead of the opposite. At that point I developed a third revenue stream: apparel with hyper-specific references to the area. 2 of my early popular designs:

1) cursive text that said “Milwaukie: Because one bowling alley just isn’t enough” – referencing the existence of Milwaukie Bowl and Kellogg bowl and their close proximity to one another.

2) an image of a sign for a mini-mart near my house (Eric’s Market) featuring a phrase on the readerboard that simply said

LOW BEER

OPEN

This led to eventually stumbling onto a brick-and-mortar space. Chris Haberman was already a well-established artist with innumerable artist contacts, and our 3rd partner was Kyle Black – a fellow screen printer who’s clientelle were more punk-rock/dive bar/biker gang than my own (Kyle passed in 2021 and we still try to celebrate his unique style whenever possible).

The most recent revenue stream is artistic vending machines. I took an online course from Taylor who owns The Venderia (https://www.vendingmagic.com/) and now I own 2 machines that I am working to fill up with clever items to be sold without needing to be manning it 24/7.

We’d love to hear about how you met your business partner.

Chris Haberman is a few years older than me, but we are both lifelong Milwaukie residents and Milwaukie High School alumni (go Mustangs!). He used to run the art galleries on the upper floor of Pioneer Place Mall and also curated the art at many Portland bars/venues. He had always been supportive of artists, myself included. I was invited to take part in The Big 500, a show where 500 artists are given a stack of 8″x8″ wood to make whatever they want and each piece was priced to sell at $40. I screen printed some various pieces for that and got to know Chris a little better. When I caught wind of an opportunity to rent a space in downtown Milwaukie, I knew that I couldn’t run a store alone, and reached out to Chris who had the Made in Milwaukie idea. Together, we brought Kyle onboard to add even more creativity to our particular soup mix, and voila! Thanks to Chris’ contacts and general enthusiasm for other artists, we have a constantly rotating inventory of tchotchks, gifts, apparel, and oddities. Somewhere along the way, we started describing our store as “home-made Hot Topic”.

Contact Info:

- Website: www.madeinmilwaukie.com www.shirtnerdery.com

- Instagram: @madeinmilwaukie @shirtnerdery

- Facebook: @madeinmilwaukie @shirtnerdery

Image Credits

Hamid Shibata Bennett