Today we’d like to introduce you to Gerard Furbershaw

Alright, so thank you so much for sharing your story and insight with our readers. To kick things off, can you tell us a bit about how you got started?

I studied architecture and industrial design in college and spent most of my career at Lunar, the design firm I cofounded in 1984. The company quickly established itself as a firm that was highly regarded by clients, employees, and the design community. Over my three-decade tenure at Lunar, our efforts amassed more than three hundred design awards. Our work was showcased in over twenty museum exhibitions, including prestigious venues like MOMA and the Cooper Hewitt Smithsonian Design Museum. Notably, in 2014, Lunar received the esteemed Cooper Hewitt Smithsonian Design Museum National Design Award, recognizing our three-decade body of work. While Lunar’s legacy stands as a remarkable collective achievement, I launched Furbershaworks in 2019 to pursue a personal legacy.

In my concluding years at Lunar, I had immersed myself in several conceptual furniture projects. I became captivated by the notion of furniture as art. These conceptual explorations unveiled a realm where objects were visual statements that weren’t confined by business requirements—a departure from the constraints of designing and producing commercial products. This revealing journey led me led to a profound transformation—from industrial design to art.

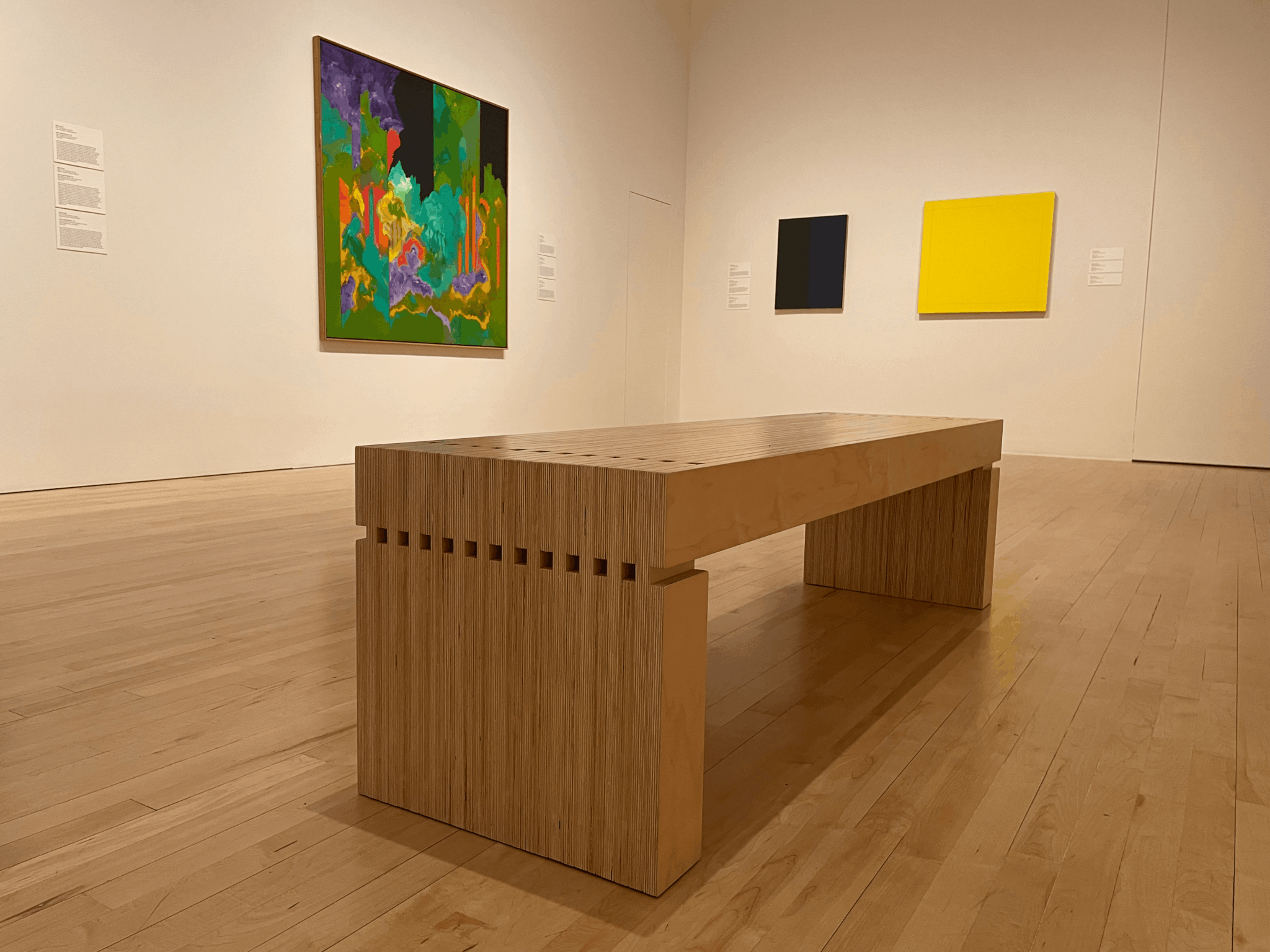

Furbershaworks serves as a platform for expressing my artistic sensibilities by creating and showcasing my art furniture. I initially focused on exploring the boundaries of art furniture through computer aided design (CAD) renderings, looking at the impact imminent production 3D printing could have on aesthetics. I then became interested in creating art furniture I could make in the present. I was drawn to layered plywood pieces that use a negative/positive space framework to create forms that appear solid visually but are in fact about half plywood and half empty space.

Over the last four years I have created a body of work that consists of more than a dozen pieces including benches, stools, tables, and a chair.

I’m sure it wasn’t obstacle-free, but would you say the journey has been fairly smooth so far?

It’s been a relatively smooth journey. Five years ago, I set out to explore the impact production 3D printing could have on the aesthetics of art furniture. Free from the constraints of conventional manufacturing and fabrication processes, the conceptual explorations provided visually fresh perspectives. While gratifying, this work wasn’t completely fulfilling as it didn’t yield tangible results. As previously mentioned, I redirected my focus to plywood art furniture that emphasized layering and negative/positive space. Initially crafted from high-end 13-ply maple plywood, I later explored Plyboo bamboo plywood.

I pursued a number of approaches to gain visibility for my work—from social media campaigns to donating pieces to museums, pitching articles to magazines, entering award programs, and selling online. None of these efforts proved fruitful. I decided to showcase my work at a large international art fair in San Francisco. The response was transformative; having my work showcased in a forum that enabled people to see and touch it in person led to significant leads and sales. While I’ll continue to use social media, pitch articles, and sell online, art fairs will now serve as the cornerstone of my program to build and sustain momentum.

Thanks – so what else should our readers know about your work and what you’re currently focused on?

While my work resides in the realm of art furniture, I rely heavily on my industrial design background to create and make my pieces. I am particularly fascinated with digital fabrication. Leveraging my CAD skills enables me to visualize and refine my pieces with computer generated renderings and use high-precision computer numerical control (CNC) machining. This technology ensures that the parts that comprise my art furniture pieces fit together precisely based on the geometry I’ve defined in CAD. It also allows me to create intricate details that conventional woodworking techniques are unable to easily achieve. Following this, I meticulously sand, apply finish, and assemble the parts. Each piece proudly bears the Furbershaworks name, seared into the wood with a branding iron.

Diverging from commercial furniture manufacturers that operate at different mass production volumes, I make art pieces one at a time. My slogan encapsulates this essence: “art you can sit on.”

We’d love to hear about any fond memories you have from when you were growing up?

When I was a child, my family moved to an expanding suburban housing development. I watched as homes progressed through sequential phases of construction—some with only foundations, others with 2×4 wood framing, and the rest fully completed. As electrical conduit, plumbing, and then exterior sheathing were added to the wood framing, it appeared to me as though nerves, blood vessels, and skin were growing around an organism’s skeleton. This experience ignited my fascination with architecture and set me on my initial educational path. My architectural studies eventually led to a degree in industrial design which launched my design career.

Contact Info:

- Website: https://www.furbershaworks.com

- Instagram: https://www.instagram.com/furbershaworks

- Facebook: https://www.facebook.com/Furbershaworks

- Youtube: https://www.youtube.com/channel/UCOjUA7m7BMu6DeKHvFA6Jnw