We caught up with the brilliant and insightful Trent Esser a few weeks ago and have shared our conversation below.

Trent, looking forward to hearing all of your stories today. Let’s start with a story that highlights an important way in which your brand diverges from the industry standard.

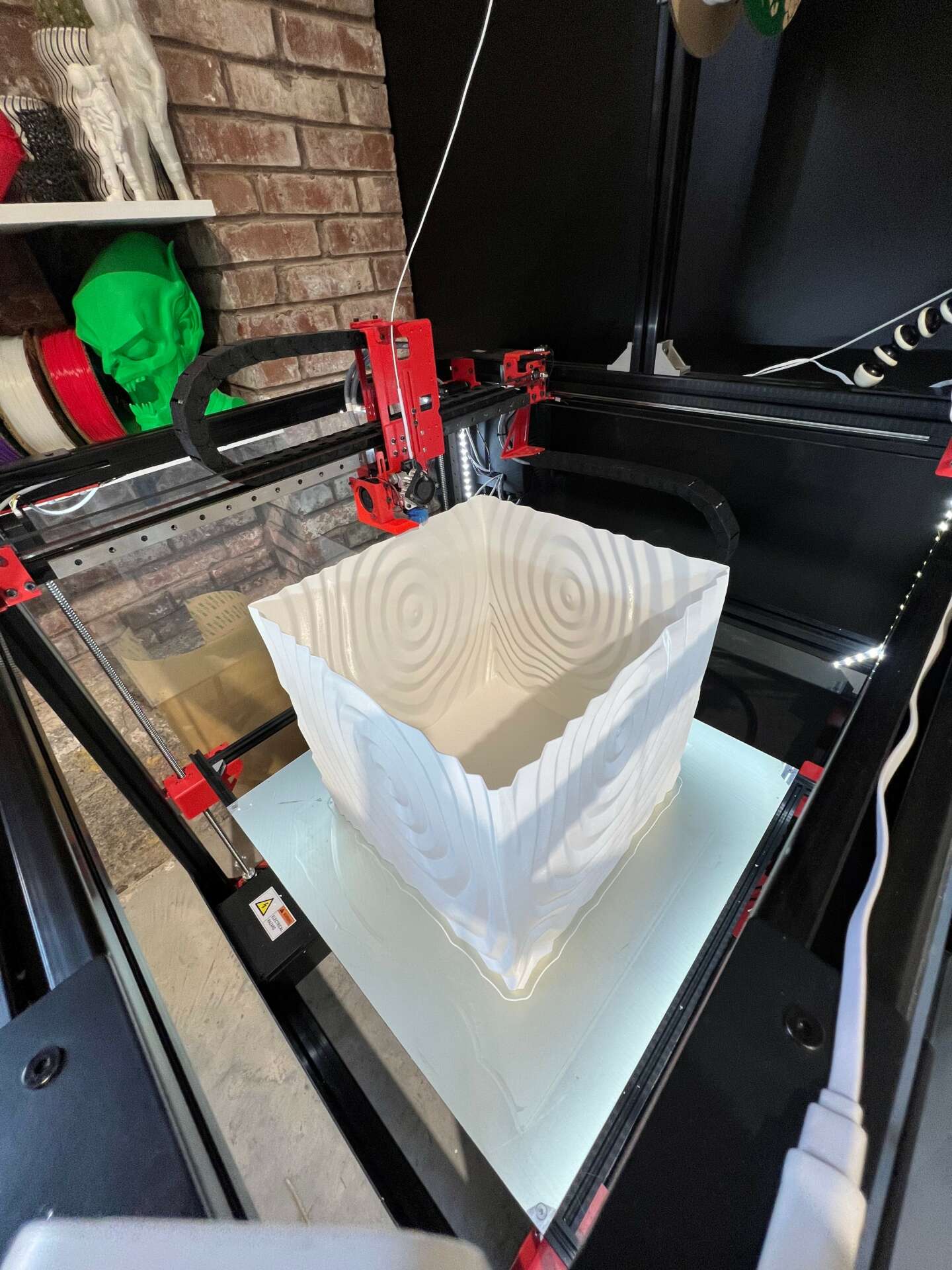

At Printerior, we take immense pride in our ability to diverge from the industry standard by pioneering sustainable mass production 3D printing services. While the manufacturing industry has long relied on conventional methods like injection molding and large aluminum mold making, we have harnessed the power of Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Large Format Additive Manufacturing (LFAM) to chart a new course for production.

Our commitment to sustainability sets us apart. In an industry often marked by significant environmental impact, we have embraced 3D printing technologies that minimize waste and energy consumption. This move towards eco-friendly practices not only aligns with our values but also addresses the growing concern for environmental responsibility.

The shift from traditional manufacturing methods to 3D printing has not been without its challenges, but our dedication to creating a more sustainable future has been the driving force behind our success. One illustrative story comes to mind – a client in the automotive industry approached us with the goal of producing lightweight and fuel-efficient components. By leveraging our diverse range of 3D printing technologies, we were able to not only meet but surpass their expectations.

In this particular case, the client had initially considered traditional manufacturing methods, which would have resulted in higher costs and longer production timelines. However, by adopting our sustainable mass production 3D printing services, they not only achieved their desired weight reduction but also experienced a significant reduction in production time and costs. This success story exemplifies how our divergence from industry norms can yield tangible benefits for our clients, both in terms of performance and economic efficiency.

Printerior’s ability to innovate and deviate from the corporate/industry standard has not only positioned us as a leader in sustainable 3D printing but has also allowed our clients to reimagine what’s possible in their respective fields. We believe that embracing change and challenging industry norms is not just a choice but a responsibility, and our journey with Printerior reflects our unwavering commitment to that principle.

Great, appreciate you sharing that with us. Before we ask you to share more of your insights, can you take a moment to introduce yourself and how you got to where you are today to our readers.

I’m Trent Esser, the founder of Printerior, a company that has redefined the landscape of manufacturing through sustainable mass production 3D printing services. My journey into this industry was fueled by a passion for sustainability and a desire to revolutionize traditional manufacturing methods.

The inception of Printerior was inspired by a vision to provide businesses with a faster, more economical, and environmentally friendly method of production. We specialize in leveraging advanced 3D printing technologies such as Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Large Format Additive Manufacturing (LFAM). This diverse range allows us to meet different market needs and replace conventional manufacturing techniques like injection molding or large aluminum mold making.

At Printerior, we pride ourselves on solving critical problems for our clients. By embracing sustainable 3D printing, we minimize environmental impact, reduce material waste, and offer efficient alternatives to traditional manufacturing. Our services cater to a wide array of industries, from small businesses looking to make their first product to aerospace manufacturers, providing solutions that are not only innovative but also economically viable.

What sets us apart is our unwavering commitment to sustainability. We believe in challenging industry norms and pushing the boundaries of what’s possible. Our 3D printing technologies not only match but surpass the quality and efficiency of traditional methods, offering our clients a unique combination of cutting-edge technology and eco-friendly practices.

One of the achievements I am most proud of is our ability to transform the manufacturing process for businesses. We’ve worked with clients across diverse sectors, helping them achieve their goals of sustainability, cost-effectiveness, and faster production times. The positive impact we’ve had on both our clients and the environment is truly gratifying.

For potential clients, followers, and fans, I want them to know that Printerior is not just a 3D printing service – it’s a commitment to a better, more sustainable future. We are driven by innovation, excellence, and a dedication to leaving a positive mark on the world. If you’re looking for a partner who can bring your ideas to life while making a difference, Printerior is the answer. Join us in reshaping the future of manufacturing, one sustainable print at a time.

Can you tell us about a time you’ve had to pivot?

In the early stages of Printerior, our journey was shaped by a mix of enthusiasm and unforeseen challenges. Securing a grant from The University of Missouri EQ Accelerator marked the beginning of our venture into LFAM (Large Format Additive Manufacturing), and we were poised to launch our business. However, fate took an unexpected turn when COVID-19 prompted a shutdown just one week after we received the grant. Navigating the complexities of international partnerships during a pandemic became a formidable challenge, prompting us to reassess our strategy.

In response to the hurdles posed by the global crisis, we made a strategic pivot. Relocating to St. Louis, we seized the opportunity to join the thriving entrepreneurial ecosystem and were fortunate to be awarded an Arch Grant. This pivotal grant not only facilitated the establishment of our facility in St. Louis but also played a crucial role in the successful launch of our materials business. The shift toward sustainable 3D printer filament production and material sales proved to be a smart move, aligning with the increasing demand for eco-friendly solutions in the 3D printing industry.

The success of our materials business became the catalyst for our expansion into a broader spectrum of 3D printing services, supported by our print farm and automation technologies. With a solid financial foundation in place, we revisited our original goal of LFAM technology. The combination of innovative LFAM capabilities and the thriving materials business created a synergistic dynamic, propelling Printerior to new heights in the industry. Our journey, from winning a grant at The University of Missouri EQ Accelerator to overcoming the challenges posed by COVID-19, underscores the importance of adaptability and resilience in the face of unforeseen circumstances. Today, Printerior stands as a testament to our ability to pivot strategically, build a sustainable business model, and push the boundaries of what’s achievable in the realm of 3D printing.

Does your business have multiple or supplementary revenue streams (like a ATM machine at a barbershop, etc)?

Printerior’s journey underscores the interconnectedness of our diverse business sectors, each reinforcing and complementing the others to create a cohesive and dynamic ecosystem. The evolution from LFAM technology to sustainable materials production and 3D printing services reflects a strategic and integrated approach. Relocating to St. Louis and establishing a facility became instrumental in shaping our trajectory, leading to the successful launch of our materials business. The synergy between materials production and 3D printing services, supported by advanced technologies like our print farm and automation capabilities, forms the backbone of our comprehensive solutions. Now, as we reintroduce LFAM technology, the strength of our diversified business model, where each sector builds on the successes of the others, propels Printerior forward, offering a holistic range of services with resilience and adaptability at its core.

Contact Info:

- Website: Printerior3D.com

- Instagram: https://www.instagram.com/printerior.designs/?hl=en

- Facebook: https://www.facebook.com/Printerior3D

- Linkedin: https://www.linkedin.com/company/printerior-designs

- Twitter: https://twitter.com/printerior3d?lang=en

- Youtube: https://www.youtube.com/@Printerior3D